Final Review Slides

advertisement

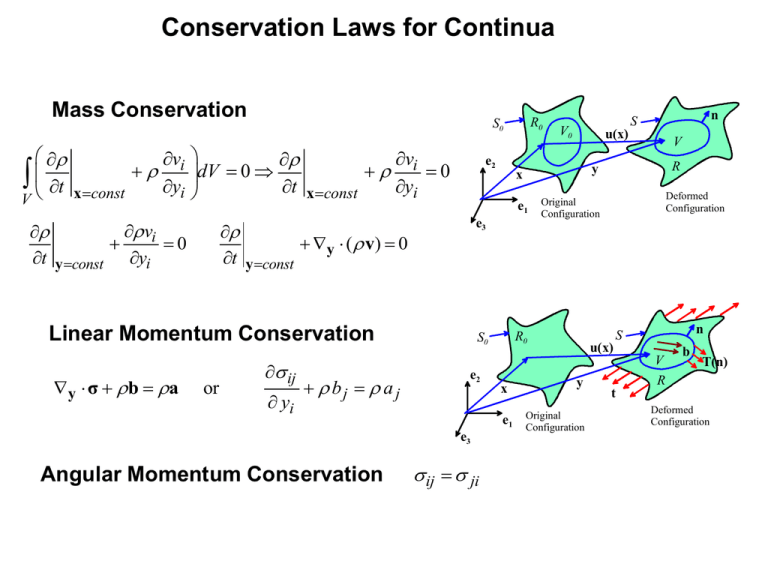

Conservation Laws for Continua Mass Conservation vi t x const yi V vi dV 0 0 t x const yi vi 0 t y const yi e2 y ( v) 0 t y const or ij yi bj a j e2 Angular Momentum Conservation x ij ji V R Deformed Configuration Original Configuration n S R0 e1 e3 u(x) y e3 S0 n S V0 x e1 Linear Momentum Conservation y σ b a R0 S0 u(x) y Original Configuration V R b T(n) t Deformed Configuration Work-Energy Relations Rate of mechanical work done on a material volume e2 d 1 (n ) r Ti vi dA bi vi dV ij Dij dV vi vi dV dt 2 A V V V u(x) y x e1 e3 n S R0 S0 V R b T(n) t Deformed Configuration Original Configuration Conservation laws in terms of other stresses S 0 b 0 a Sij xi 0 b j 0 a j F T 0b 0a Mechanical work in terms of other stresses d 1 r b v dV S F dV v v dV ii ij ji 0 dt 2 0 i i 0 A V V0 V0 d 1 (n ) r Ti vi dA bivi dV ij Eij dV0 0vivi dV0 dt 2 A V V0 V0 Ti(n)vi dA ik F jk 0b j 0 a j xi Principle of Virtual Work (alternative statement of BLM) 1 vi v j Dij 2 y j yi vi Lij y j R0 S0 e2 e3 If ij Dij dV V V dvi vi dV dt Then bi vi dV ti vi dA 0 V S2 ji y j bi ni ij t j on dvi dt S2 y x e1 u(x) S2 V t Deformed Configuration Original Configuration for all b vi S1 Thermodynamics S S0 Temperature Specific Internal Energy Specific Helmholtz free energy s Heat flux vector q External heat flux q Specific entropy s First Law of Thermodynamics Second Law of Thermodynamics e2 R e1 e3 t Original Configuration d ( KE) Q W dt b R0 q ij Dij i q t xconst yi dS d 0 dt dt s (qi / ) q 0 t yi 1 ij Dij qi s 0 yi t t Deformed Configuration Transformations under observer changes Transformation of space under a change of observer y* y*0 (t ) Q(t )(y y0 ) n Inertial frame e2 b y e1 dQ T Ω Q dt e3 All physically measurable vectors can be regarded as connecting two points in the inertial frame Deformed Configuration e2* n* e3* e2* These must therefore transform like vectors connecting two points under a change of observer Observer frame b* y* Deformed Configuration b* Qb n* Qn v* Qv a* Qa Note that time derivatives in the observer’s reference frame have to account for rotation of the reference frame dy d T * * dy* dy*0 v Qv Q Q Q (y y 0 (t )) Ω(y* y*0 (t )) dt dt dt dt * * a Qa Q d 2y dt 2 Q d2 dt 2 T Q (y * y*0 (t )) dy* dy*0 (t ) 2 dΩ * * Ω ) (y y 0 (t )) 2Ω( 2 2 dt dt dt dt dt d 2 y* d 2 y*0 Some Transformations under observer changes The deformation mapping transforms as y* (X, t ) y*0 (t ) Q(t ) y(X, t ) y0 y* y The deformation gradient transforms as F Q QF X X The right Cauchy Green strain Lagrange strain, the right stretch tensor are invariant * C* F*T F* FT QT QF C E* E U* U The left Cauchy Green strain, Eulerian strain, left stretch tensor are frame indifferent B* F*F*T QFFT QT QCQT The velocity gradient and spin tensor transform as V* QVQT L* F*F*1 QF QF F 1QT QLQT Ω W* (L* L*T ) / 2 QWQT Ω The velocity and acceleration vectors transform as dy d T * dy* dy*0 * v Qv Q Q Q (y y 0 (t )) Ω(y* y*0 (t )) dt dt dt dt * dy* dy*0 (t ) 2 dΩ * * a Qa Q Q Q (y Ω ) (y y 0 (t )) 2Ω( 2 2 2 2 dt dt dt dt dt dt dt (the additional terms in the acceleration can be interpreted as the centripetal and coriolis accelerations) * d 2y d2 T * y*0 (t )) d 2 y* d 2 y*0 The Cauchy stress is frame indifferent σ* QσQT (you can see this from the formal definition, or use the fact that the virtual power must be invariant under a frame change) The material stress is frame invariant Σ* Σ The nominal stress transforms as S* J (QF)1 QσQT JF1 σQT SQT (note that this transformation rule will differ if the nominal stress is defined as the transpose of the measure used here…) Some Transformations under observer changes Objective (frame indifferent) tensors: map a vector from the observed (inertial) frame back onto the inertial frame t nσ n Inertial frame e2 σ* QσQT D* QDQT b y e1 e3 Invariant tensors: map a vector from the reference configuration back onto the reference configuration e2* T0 m Σ Σ* Σ Deformed Configuration n* e3* e2* Observer frame Mixed tensors: map a vector from the reference configuration onto the inertial frame dy Fdx F* QF b* y* Deformed Configuration Constitutive Laws Equations relating internal force measures to deformation measures are known as Constitutive Relations General Assumptions: 1. Local homogeneity of deformation (a deformation gradient can always be calculated) 2. Principle of local action (stress at a point depends on deformation in a vanishingly small material element surrounding the point) e2 e1 e3 Original Configuration Restrictions on constitutive relations: 1. Material Frame Indifference – stress-strain relations must transform consistently under a change of observer 2. Constitutive law must always satisfy the second law of thermodynamics for any possible deformation/temperature history. 1 ij Dij qi s 0 yi t t Deformed Configuration Fluids Properties of fluids • • No natural reference configuration Support no shear stress when at rest S e2 y b R t Kinematics • e1 Only need variables that don’t depend on ref. config Lij ai vi y j Lij Dij Wij e3 Dij (Lij L ji ) / 2 Wij (Lij L ji ) / 2 i ijk Deformed Configuration vk ijk Wij y j vi v y v v v i k i Lik vk i Dik Wik vk i t x const yk t t y const t y const t y const k i i i v 1 1 (vk vk ) 2Wik vk i (vk vk ) ijk j vk 2 yi t y const 2 yi k Conservation Laws vi Dkk 0 or 0 t xconst t y const yi v v bi i vk i yk y j t y const i ji q ij Dij i q t xconst yi ij ji 1 ij Dij qi s 0 yi t t General Constitutive Models for Fluids Objectivity and dissipation inequality show that constitutive relations must have form Internal Energy ˆ( , ) s sˆ( , ) Entropy ˆ ( , ) s Free Energy Stress response function ij ˆij ( , , Dij ) ˆeq ( , )ij ˆijvis ( , , Dij ) Heat flux response function qi qˆi , , , Dij yi In addition, the constitutive relations must satisfy ˆeq 2 ˆeq ˆ sˆ 2 cv where cv ( , ) 2ˆ 2 ˆ sˆ ˆeq ˆeq 2 2 cv ˆeq 2 2 ˆ ijvis ( , , Dij ) Dij 0 qi , , yi 0 yi Constitutive Models for Fluids ij ˆij ( , , Dij ) ˆeq ( , )ij ˆijvis ( , , Dij ) ˆ ( , ) s Elastic Fluid ˆ ( ) p ( 1) Ideal Gas cv Newtonian Viscous ˆ ( , ) Non-Newtonian ij eq ( )ij cv cv log R log s0 ij p ij R ij ij ( eq ( , ) ( , ) Dkk )ij 2 ( , )( Dij Dkkij / 3) ˆ ( , ) ij eq ( , )ij 1( I1, I 2 , I3 , , )ij 2 ( I1, I 2 , I3 , , ) Dij 3 ( I1, I 2 , I3 , , ) Dik Dkj Derived Field Equations for Newtonian Fluids Unknowns: p, vi vi Dkk 0 or 0 t xconst t y const yi Must always satisfy mass conservation Combine BLM ji y j bi ai ai vi v v 1 vk i i (vk vk ) ijk j vk yk t y const t y const 2 yi i k v j 1 v Dij i 2 y j yi With constitutive law. Also recall Compressible Navier-Stokes p 2 ( , ) Dij Dkk ij / 3 bi ai yi y j 2 2 v j 1 eq 2 vi b a yi y j y j 3 y j yi i i With density indep viscosity For an incompressible Newtonian viscous fluid 1 p 2vi b a yi y j y j i i Incompressibility reduces mass balance to For an elastic fluid (Euler eq) p eq ( , ) ( , ) Dkk eq yi bi vi 0 yi vi 1 (vk vk ) ijk j vk t y const 2 yi k Derived Field Equations for Fluids i ijk Recall vorticity vector vk ijk Wij y j ijk ak i v Dij j k i y j t xconst yk Vorticity transport equation (constant temperature, density independent viscosity) 2 v 2i 1 2 2 vl vk ijk ijk (bk ) Dij j k i i y j y j 2 y j 3 yl yk y j yk t yl yl For an elastic fluid ijk For an incompressible fluid v (bk ) Dij j k i i x j yk t xconst 2i ijk (bk ) Dij j i y j y j x j t xconst If flow of an ideal fluid is irrotational at t=0 and body forces are curl free, then flow remains irrotational for all time (Potential flow) x const Derived field equations for fluids For an elastic fluid • Bernoulli H For irrotational flow For incompressible fluid eq 1 vi vi constant 2 H p eq 1 vi vi constant 2 1 vi vi constant 2 along streamline everywhere Normalizing the Navier-Stokes equation Incompressible Navier-Stokes v 1 p 2 vi 1 bi i (vk vk ) ijk j vk yi y j y j t y const 2 yi k L Characteristic length V Characteristic velocity f Characteristic frequency P Characteristic pressure change yi Lyˆi vi Vvˆi t ftˆ p pˆ P b gbˆ V L i Normalize as vˆi vˆi pˆ 1 2vˆi 1 ˆ Eu bi St vˆi 2 ˆ yˆi Re yˆ j yˆ j Fr t y const yˆi k Reynolds number Re VL / Froude number Fr V / gL Eu P / V 2 St fL / V Strouhal number Euler number Limiting cases most frequently used vˆi vˆi pˆ 1 2vˆi 1 ˆ Eu bi St vˆi 2 yˆi Re yˆ j yˆ j Fr tˆ y const yˆi k Ideal flow Re vˆi vˆi pˆ 1 ˆ Eu bi St vˆi 2 ˆ yˆi Fr t y const yˆi k Stokes flow eq yi bi vi 1 (vk vk ) ijk j vk t y const 2 yi k V 0 vˆ pˆ 1 2vˆi bˆi i yˆi Re yˆ j yˆ j tˆ y const k v 1 p 2 vi bi i yi y j v j t y const k Solving fluids problems: control volume approach Governing equations for a control volume (review) B R Example v1 A i j Steady 2D flow, ideal fluid Calculate the force acting on the wall Take surrounding pressure to be zero 1 A4 v0 A0 A5 B d n σdA bdV vdV ( v) v ndA dt R R B ( p0n jdA) j A0 0v02 sin j A v2 ( p p0 )dAj 0 A3 F A0 0v02 sin j A2 A3 Exact solutions: potential flow If flow irrotational at t=0, remains irrotational; Bernoulli holds everywhere Irrotational: curl(v)=0 so yi vi 2 0 0 yi yi yi Mass cons 1 vi vi constant 2 t p Bernoulli vi a 2V ( y V t ) r 2 r ( y V t )( y V t ) V e2 a e1 Exact solutions: Stokes Flow Steady laminar viscous flow between plates Assume constant pressure gradient in horizontal direction V v 1 p vi p f bi i 0 2 yi y j v j t y const L y 2 k 2 2 y2 h y1 Solve subject to boundary conditions p y v V 2 y2 (h y2 ) e1 h 2L V p h σ y2 h L 2 Exact Solutions: Acoustics Assumptions: Small amplitude pressure and density fluctuations Irrotational flow Negligible heat flow Approximate N-S as: v p bi i yi t y const k p cs2 t t For small perturbations: Mass conservation: Combine: 2vi 2 p bi yi yi yi t cs p s const v i 0 t xconst yi 2 vi 2v j t yi y j cs2 2 0 2 t 2 (Wave equation) cs2 0 yi yi yk const 2vi 2 p yi t t 2 yk const Wave speed in an ideal gas Assume heat flow can be neglected Entropy equation: cv q s i q s const t xconst yi cv cv log R log s0 p R s cv log R log s0 R/cv exp[(s s0 ) / cv ) R / cv 1 Hence: cs so p k p p k 1 R s const Application of continuum mechanics to elasticity Modulus G' (N/m2) u S S0 e2 y e3 Glassy Viscoelastic 109 x R0 e1 b Original Configuration R Rubbery t Deformed Configuration Melt 5 10 Glass Transition temperature Tg (frequency)-1 Material characterized by General structure of constitutive relations Fij ij u S S0 e2 x R0 y e1 e3 Original Configuration b R t Deformed Configuration ui x j S JF1 σ Cij Fki Fkj Bij Fik F jk Qi JFik1qk Sij JFik1 kj Σ JF1 σ FT ij JFik1 kl F jl1 S ji x j 0bi 0 vi t x const i 1 1 ij Cij Qi 0 s 0 2 xi t t F* QF B* F*F*T QBQT C* F*T F* C Σ* Σ Frame indifference, dissipation inequality ˆ ˆ ij 2 0 Cij ˆ ij 2 0 sˆ Cij sˆ ˆ Qk 0 xk Forms of constitutive relation used in literature I1 I1 trace(B) Bkk I2 1 2 1 I1 B B I12 Bik Bki 2 2 I 3 det B J 2 I1 J 2/3 I2 = Bkk J 2/3 1 B B 1 2 Bik Bki I2 I12 I1 4 / 3 J 4/3 2 J 4/3 2 J J det B B 12b(1) b(1) 22b(2) b(2) 32b(3) b(3) • Strain energy potential W 0 W (F) Wˆ (C) U (I1, I 2 , I3 ) U (I1, I 2 , J ) U (1, 2 , 3 ) 1 W Fik J F jk ij ij ij 2 U U I1 I 2 I3 I1 U U B B B ij ij ik kj 2 I3 I I 2 3 U U 2 1 U U U ij 1 U I1 B I 2 I B B ij 2/ 3 ij 1 2 ik kj 4/ 3 I J J I I I I 3 J J 2 1 2 2 1 ij 3 U (3) (3) 1 U (1) (1) 2 U (2) (2) bi b j bi b j b b 123 1 123 2 123 3 i j Specific forms for free energy function K U 1 ( I1 3) 1 ( J 1)2 2 2 • Neo-Hookean material ij 1 1 1 Bij Bkk ij 2 Bkk Bij [ Bkk ]2 ij Bik Bkj Bkn Bnk ij K1 J 1 ij 5/ 3 7 / 3 3 3 3 J J U N i j 1 • Arruda-Boyce 1 Bij Bkk ij K1 J 1 ij 5/ 3 3 J 1 • Generalized polynomial function U 1 K U 1 ( I1 3) 2 ( I 2 3) 1 ( J 1)2 2 2 2 • Mooney-Rivlin • Ogden ij N Cij ( I1 3)i ( I 2 3) j N Ki ( J 1)2i 2 i 1 2i K (1 i 2 i 3 i 3) 1 ( J 1)2 2 2 i 1 i 1 K 1 11 2 U ( I1 3) ( I12 9) ( I13 27) ... J 1 2 4 20 1050 2 2 Solving problems for elastic materials (spherical/axial symmetry) • Assume incompressiblility e3 eR • Kinematics rr σ 0 0 0 0 0 0 Frr F 0 0 Brr B 0 0 2 0 B 0 dr r Brr B B dR R dr r Frr F F dR R 2 dr r 1 dR R • Constitutive law 0 0 F 0 F 0 e1 e2 2 r 3 a3 R3 A3 U rr 2 0 0 B e r e I1 I1 I1 U 2 I 2 U U 2 U Brr p Brr I 2 3 I1 3 I 2 I 2 U U I U 2 I U U 2 1 2 I1 2 B p B I 2 3 I1 3 I 2 I 2 I1 • Equilibrium (or use PVW) • Boundary conditions d rr 1 2 rr 0br 0 dr r ur (a) ga rr (a) ta ur (b) gb rr (b) tb (gives ODE for p(r) Linearized field equations for elastic materials Approximations: • Linearized kinematics • All stress measures equal • Linearize stress-strain relation S S0 e2 R ui ui* (t ) ij Cijkl ( kl kl ) ij ni t*j (t ) on 1R Elastic constants related to strain energy/unit vol ε Sσ αT t e1 e3 1 ui u j ij 2 x j xi ij xi b j Deformed Configuration Original Configuration 2u j t 2 on 2 R ˆij 2U Cijkl kl ij kl ˆij 2U ij ij σ C(ε αT ) Isotropic materials: ij 1 ij kk ij Tij E E b R0 ij E ET kk ij ij ij 1 1 2 1 2 Elastic materials with isotropy 1 1 11 1 22 0 33 E 0 0 23 (1 )(1 2 ) 0 13 0 0 12 0 0 0 1 11 22 33 1 2 23 E 0 0 213 212 0 ij 1 0 0 0 1 0 0 0 1 ij kk ij Tij E E 0 0 0 1 2 2 0 0 0 0 0 0 1 2 2 0 11 22 0 33 ET 2 23 1 2 0 213 212 1 2 2 0 0 0 1 1 1 0 0 0 0 0 0 11 1 1 0 0 0 22 1 0 0 0 33 T 2 1 0 0 23 0 0 0 2 1 0 13 0 0 2 1 12 0 ij E ET kk ij ij ij 1 1 2 1 2 Solving linear elasticity problems spherical/axial symmetry e3 RR 0 0 0 0 • Kinematics • Constitutive law • Equilibrium du RR dR 0 0 RR 0 0 0 0 0 0 eR e1 u R du 2 dR ET 1 1 u 1 2 1 R RR 1 E 1 1 2 d RR 1 2 RR 0bR 0 dR R d 2u dR 2 • Boundary conditions 2 du 2u d 1 d 1 d T 1 1 2 R2u 0b( R) 2 2 R dR R dR R dR E 1 1 dR ur (a) ga rr (a) ta ur (b) gb rr (b) tb e R e e2 Some simple static linear elasticity solutions Navier equation: 2uk 2ui bi 0 2ui 1 0 1 2 xk xi xk xk t 2 ui Potential Representation (statics): 2(1 ) 1 xk k i E 4(1 ) xi i Point force in an infinite solid: Pi 4 R 2 i 0bi x j x j 0 ui (1 ) Pk xk xi (3 4 ) Pi 8 E (1 ) R R 2 ij Pi x j Pj xi 3Pk xk xi x j Pk xk ij (1 2 ) R R 8 E (1 ) R 2 R3 ij Pi x j Pj xi ij Pk xk 3Pk xk xi x j (1 2 ) R 8 (1 ) R 2 R3 (1 ) 1 Point force normal to a surface: i ui (1 )i3 R P (1 2 )(1 ) log(R x3 ) R i3 (1 2 ) x (1 ) P x3 xi 3i i 3 (3 4 ) 2 E R R R x3 R e3 xi x j x3 (1 2 )(2 R x3 ) ij 3 xi x j ij x32 x3 i 3 x j j 3 xi 2 3 2 2 R R R( R x3 ) P 2 0bi xi xk xk ( R x )2 i3 j3 ij (1 2 ) R 2 3 e1 Simple linear elastic solutions 33 0 Spherical cavity in infinite solid under remote stress: e2 (1 ) 0 a3 (1 ) 0 (5 1) i x3 i3 xi 5 x3 i3 (1 ) R3 (7 5 ) 2(1 2 ) a 2 2 (1 ) 0 a (1 ) 0 (7 5 ) 2 2 2 2 3x3 a (3x3 R ) R a (1 ) R3 (7 5 ) 2(1 2 ) R 2 3 (1 ) 0 5(5 4 ) 2 ui 2 E (7 5 ) a3 6 3 (7 5 ) R e1 e3 a5 x3 i3 R5 2 (5 6) (1 ) (7 5 ) a3 3 3 (7 5 ) R a5 5 x32 1 2 xi R5 R 3a3 xi x j x32 a2 a2 3 5 4 6 5 5 10 ij 0 2(7 5 ) R3 R 2 2(7 5 ) R5 R2 R 2 ij 3a3 i3 j 3 3 a5 15a x3 ( x j i3 xi j 3 ) a 2 (7 5 ) 5(1 2 ) 3 3 5 R2 (7 5 ) R R (7 5 ) R5 a3 Dynamic elasticity solutions Plane wave solution Navier equation ui ai f (ct xk pk ) 2uk 2ui bi 0 2ui 1 0 1 2 xk xi xk xk t 2 Solutions: 0c2 ak ai pi 0 1 2 pi ai pk 0 c2 c22 0 / ai pi c2 cL2 2 (1 ) / 0 (1 2 )