API presentation

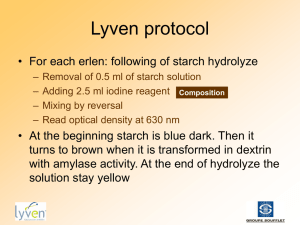

advertisement

NEW WORK GROUP Revision of Starch Specifications in API 13 A Saleh Al-Ammari Saudi Aramco June 29th, 2010 What is Starch? Starch or amylum is a carbohydrate consisting of a large number of glucose units joined together by glycosidic bonds. This polysaccharide is produced by all green plants as an energy store. It is contained in potatoes, wheat, maize (corn), rice, and cassava. Drilling Fluid Materials API SPECIFICATION 13A SECTION 11 STARCH 11.1 Description a. Drilling grade starch can be manufactured from several kinds of native starches. The starch should be made cold water hydratable (pregelatinized) and may be treated further in such a way that it is suitable for use as a filtrate reducing agent in water-base drilling fluids. b. Drilling grade starch should be free-flowing and free from lumps. Drilling grade starch shall be deemed to meet this specification if a composite sample representing no more than one day's production conforms to the physical requirements of Table 11.1, represents the product produced, and is controlled by the manufacturer. Drilling Fluid Materials API SPECIFICATION 13A Table 11.1 - STARCH PHYSICAL REQUIREMENTS Requirement Specification Suspension Properties: Viscometer Dial Reading at 600 rpm in 40 g/L Salt Water in Saturated Salt Water 18, maximum 20, maximum Filtrate Volume in 40 g/L Salt Water in Saturated Salt Water 10 cm3, maximum 10 cm3, maximum Residue Greater than 2000 micrometers No residue Example 1 – Clay free mud Formulation and order of addition: (one barrel) Average Fluid Properties: Water bbl : 0.97 Density lb/ft3 : 66 XC-Polymer lb : 1.0 PV cp : 10 Starch lb : 4.0 YP lb/100ft2 : 14 Lime lb : 0.5 10 sec gel lb/100ft2 : 3 CaCO3 “fine” lb : 32.0 10 min gel lb/100ft2 : 6 Filtrate : 10 : 9.5 pH ml/30min Example 1 – Clay free mud Formulation and order of addition: (one barrel) Average Fluid Properties: Water bbl : 0.97 Density lb/ft3 : 66 XC-Polymer lb : 1.0 PV cp : 10 Starch lb : 4.0 YP lb/100ft2 : 14 Lime lb : 0.5 10 sec gel lb/100ft2 : 3 CaCO3 “fine” lb : 32.0 10 min gel lb/100ft2 : 6 Filtrate : NC : 9.5 pH ml/30min Example 2 – Bentonite mud Formulation and order of addition: (one barrel) Average Fluid Properties: Water bbl : 0.92 Density pcf : 80 Bentonite lb : 10.0 PV cp : 18 Lime lb : 0.5 YP lb/100ft2 : 16 Starch lb : 4.0 Gels lb/100ft2 : 3/6 Barite lb : 122 Filtrate ml/30 min : 8 pH : 9 - 10 Example 2 – Bentonite mud Formulation and order of addition: (one barrel) Average Fluid Properties: Water bbl : 0.92 Density pcf : 80 Bentonite lb : 10.0 PV cp : 18 Lime lb : 0.5 YP lb/100ft2 : 16 Starch lb : 10.0 Gels lb/100ft2 : 3/6 Barite lb : 122 Filtrate ml/30 min : 8 pH : 9 - 10 Example 3 – CaCl2 mud Formulation and order of addition: (one barrel) Average Fluid Properties: Water bbl : 0.67 Density lb/ft3 : 89 Defaomer gal : 0.01 PV cp : 16 XC-Polymer lb : 1.0 YP lb/100ft2 : 20 Starch lb : 6.0 10 sec gel lb/100ft2 : 4 Lime lb : 0.5 10 min gel lb/100ft2 : 8 CaCl2 lb 245 Filtrate ml/30min : 6 22.0 pH : 9.5 : 357k CaCO3 “fine” lb : Chloride mg/l Example 3 – CaCl2 mud Formulation and order of addition: (one barrel) Average Fluid Properties: Water bbl : 0.67 Density lb/ft3 : 89 Defaomer gal : 0.01 PV cp : 16 XC-Polymer lb : 1.0 YP lb/100ft2 : 20 Starch lb : 12.0 10 sec gel lb/100ft2 : 4 Lime lb : 0.5 10 min gel lb/100ft2 : 8 CaCl2 lb 245 Filtrate ml/30min : 6 22.0 pH : 9.5 : 357k CaCO3 “fine” lb : Chloride mg/l Conclusions 1. Increase in concentration 2. Thermal degradation at lower temperature 3. Use of expensive fluids loss additives 4. Encounter more operational problems 5. Face interrupted inventories 6. Difficulty in controlling the quality 7. Ineffective API monogram Suggestions 1. Improve the suspension properties 2. Specify more particles size distributions 3. Include temperature limitation 4. Introduce classifications 5. Develop analytical methods 6. Standardize nomenclature