Teledyne AQMS Training Part2

advertisement

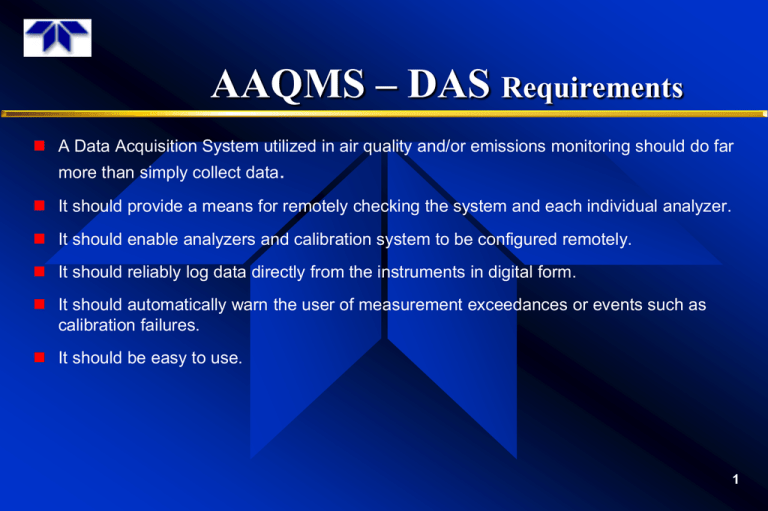

AAQMS – DAS Requirements A Data Acquisition System utilized in air quality and/or emissions monitoring should do far more than simply collect data. It should provide a means for remotely checking the system and each individual analyzer. It should enable analyzers and calibration system to be configured remotely. It should reliably log data directly from the instruments in digital form. It should automatically warn the user of measurement exceedances or events such as calibration failures. It should be easy to use. 1 Teledyne – Win AQMS DAS WinAQMS is a Windows® based system which provides full control over the entire system (remote and onsite) enabling automatic calibrations to be performed and system errors to be monitored. WinAQMS interfaces to analyzers via a RS232 multi-drop serial link, through a USB link or via TCP/IP network link. This allows it to collect data directly from the instruments in digital format thus eliminating digital to analog and analog to digital conversion errors. The bi-directional interface also allows a remote central computer, running Teledyne WinCollect software, to access full control and diagnostics of the analyzers used and data to be collected remotely. The Data Acquisition system has sufficient data storage to hold well over thirty years worth of historical data. 2 Main Features : Win AQMS (DAS) Supports remote communication from anywhere in the world enabling full control over the pollution monitoring system and direct interfacing with supported analyzers Full control over calibration cycle periods Remote communication through dial-up, Ethernet, satellite telephone networks, 3G network as well as short haul modems Solid state hard disk drive eliminates risk of mechanical failure due to shock, high temperatures, vibration and harsh environments. Data retrieval via USB Memory Stick or Mini SD card in the event communication networks are unavailable "Industry Standard" RS232 and USB Communication enables digital communication with a wide range of supported monitoring equipment Captures minimum, maximum, average values and standard deviations Creates calculated channels that allows the user to apply calculations to data (logged automatically) Fifth Generation Data Acquisition & Control System based on 30 years of field experience Data storage space for over thirty years of 5 minute historical data Lightning & surge protection facilities Windows XP PRO Compatible 3 Specifications : Win AQMS (DAS) CPU: ........ 1.6 Ghz+ RAM: 1 Gbytes Hard Drive Config.: Solid State 64 Gbytes Display Driver: Supporting up to 1929 x 1200 (allows dual screen) Operating System: Windows XP Data Storage Format: Data Stored in Ascii format Data Averaging Periods: Up to 4 independent data sets Selectable between 1 minute and 7 days Calibration control: Automatic Span and Zero control. Calibration data is stored separately Communication ports: 1 RS232 /RS485 serial ports standard, 6 x USB2.0 Ports Networking :1000 Base T Ethernet 802.11g WLAN Power: 12 volts < 7 Watt power supply. Size: 10.1 x 11.5 x 2.7 cm 370 grams 4 AAQMS with DAS 5 AAQMS – Sample Conditioning System 6 AAQMS Analyzer Panel 7 Mobile AAQMS Station 8 AAQMS Mobile Shelter 9 AAQMS Cabinet – Rear & Front Side 10 AQMS Calibration Procedure 11 AQMS Calibration Procedure 12 AQMS Calibration Procedure 1] SO2 CALIBRATION: 6400E (Refer manual for reference) The following three-step procedure assumes that the instrument does not have any of the available zero/span (Z/S) or IZS valve options installed. Chapter 7 contains instructions for calibrating instruments with valve options. Chapter 8 contains directions for performing for EPA protocol calibrations. The initial calibration should be carried out with the analyzer’s reporting range for SINGLE range mode with a range span of 500 PPB (factory default settings for most units). This will enable you to compare your results to the factory calibration. STEP ONE: Set/verify the analog output reporting range of the 13 M100E: AQMS Calibration Procedure 14 AQMS Calibration Procedure STEP TWO: Set the expected SO2 span gas concentration. 15 AQMS Calibration Procedure STEP THREE: Perform the zero/span calibration procedure: 16 AQMS Calibration Procedure Check the value of the SLOPE and OFFSET test functions (see Section 6.2.1) to verify that they are within the limits listed in Table 7-5) Model 100E analyzer is now ready for operation. 17 AQMS Calibration Procedure 2] NOX CALIBRATION: 9110E (Refer manual for reference) The initial calibration should be carried out using the 500ppb range, a span gas with about 400 ppb NO and with the unit set for SINGLE range, which will enable you to compare your calibration results to the factory calibration as listed on the Final Test and Validation Data sheet. The following three-step procedure assumes that the instrument does not have any of the available zero/span (Z/S) valve options installed. Chapter 1 contains instructions for calibrating instruments with Z/S valve options, Chapter 1 for EPA protocol calibration. STEP ONE: Set the analog output range of the M200E: 18 AQMS Calibration Procedure 19 AQMS Calibration Procedure STEP TWO: Set the expected NO and NOX span gas concentration. If you supply NO gas to the analyzer, the values for expected NO and NO2 need to be identical. 20 AQMS Calibration Procedure Perform the zero/span calibration procedure: 21 AQMS Calibration Procedure 22 AQMS Calibration Procedure The Model 200E analyzer is now ready for operation. 3] CO CALIBRATION: 7001E (Refer manual for reference) Set the expected CO span gas concentration 23 AQMS Calibration Procedure Perform the Zero/Span Calibration Procedure The Model GFC7001E Analyzer is now ready for operation. 24 AQMS Calibration Procedure 4] O3 CALIBRATION: 7001E (Refer manual for reference) The O3 span concentration value automatically to 400.0 PPB and it is recommended that an O3 calibration gas of that concentration be used for the initial calibration of the unit. To verify that the analyzer span setting is set for 400 PPB 25 AQMS Calibration Procedure To perform an initial Calibration of the Model 400E photometric ozone analyzer, press 26 AQMS Calibration Procedure 27 AQMS Calibration Procedure The Model 400E ANALYZER IS NOW READY FOR OPERATION. 5] VOC CALIBRATION: 4060 (Refer manual for reference) The analysis has 2 modes: Sample Mode and Analysis Mode. 1) Sample Mode: In this mode, the Analyzer configures the operational valve to back flush the column and charge the sample loop. The sample mode is programmed to continue for a 7 minute period by factory default; however, it is usually modified to match the needs of a particular process. It is possible to set the Sample Mode duration up to 30 minutes. 28 AQMS Calibration Procedure 2) Analysis Mode During this mode, the Analyzer configures the operational valve to feed the gas in the sample loop through the column to the detector. If configured to do so, the Analyzer may read the detector for a 5 second period programmed somewhere during this mode to obtain a baseline reading for further calculation. This mode is usually programmed to continue until the compound of interest is fully calculated from the column. It is possible to set it up to 10 minutes. During the Analysis Mode, a ‘Peak Detect’ period is programmed at which time the Analyzer reads the Detector Output. The Analyzer stores the maximum reading during this time and uses the value in conjunction with the baseline value to calculate the concentration of the compound of interest. The calculation is performed at the end of the ‘Peak Detector’ period and the result is displayed at the end of Analysis Mode. 29 AQMS Calibration Procedure 30 AQMS Calibration Procedure 31 AQMS Calibration Procedure 32 SO2 Analyzer – Model 6400E Maintenance Schedule Item Action Priority Frequency Cal Check Particulate filter Change particle filter Mandatory Weekly or As Needed No Flow controller Replace sintered filter & O-rings Mandatory Annually Pump Rebuild-Kit Mandatory Annually Yes Zero/span calibration Zero/span calibration As Needed Annually or as needed Yes Sample Chamber windows and Filters Clean As Needed As necessary Yes TEST functions Review and evaluate Recommended Weekly No Pneumatic sub-system Check for leaks in gas flow paths Recommended Annually or after repairs involving pneumatics Yes on leaks, else no PMT Sensor Hardware Calibration Low-level hardware calibration Recommended On PMT or preamp changes Yes Yes 33 NO x Analyzer - 9110 Maintenance Schedule 34 CO Analyzer – GFC 7001E Maintenance Schedule 35 O3 Ozone Analyzer – Model 400E Maintenance Schedule 36 Zero Air Generator - Model 701 Maintenance Before any maintenance cycle power on/off, drain any water in bowl Do not loosen any tubing connection while the 701 is running. Before working on the 701 plumbing turn off the 701, wait for the pressure gauge to read zero. (This may require that you loosen the rear panel bulkhead union to allow the air to bleed away.) Even though the front panel power switch is off, there is line voltage present at the power entry terminals, power switch terminals and on the control board. For added safety, remove the power cord from the rear panel receptacle. Occasionally, depending upon the local conditions, check the inside of the 701 for excessive dirt or dust. Particularly, check the cooling fan, cooling coil and compressor fan inlet. Remove any dirt or dust with a vacuum cleaner. Do not use an air jet. This will only redistribute the dirt and will not remove it. 37 VOC Analyzer – Model 4060 GC Routine Maintenance The pressure gauges and flow rate should be checked weekly. All support gases need to be replaced when the primary gauge reaches 100PSIG. Span calibration required whenever replaced or flame is re-ignited. Air/Fuel cylinder is 38 VOC Analyzer – Model 4060 GC Routine Maintenance Item Front Panel Pressure Gauge Setting Support Gases Cylinder press. Action Air Set pressure recommended as Fuel Set pressure recommended as Carrier Set pressure recommended as Fuel Replace cylinder when primary pressure reaches 100psig. Frequency Remarks Daily/Weekly Ensure that press setting is same as per previous calibration. Daily/Weekly Ensure that press setting is same as per previous calibration. Daily/Weekly Very critical. Do not disturb on front gauge. Ensure that Cylinder outlet pressure is at 80 to 90psig. As on required Whenever cylinder replaced, perform span calibration. 39 VOC Analyzer – Model 4060 GC Routine Maintenance Item Action Front Panel Pressure Gauge Setting Air Calibration Gas Cylinders Span Sample Bypass flow Temp. Set pressure recommended as Calibration Sample / Zero / Set flow @1LPM Span recommended Frequency Remarks Daily / Weekly Ensure that press setting is same as per previous calibration. Weekly as Daily / Weekly Whenever cylinder perform calibration. replaced, Ensure that flow setting is same as per previous calibration. Check PV/SV values. All Daily / Weekly Ensure that GC Temperature is as FID / GC/Sample temp. should maintained per PV value. 40 as per SV. Zero Air Generator - Model 701 Maintenance Schedule 41 MFC – Model 700E Maintenance Schedule 42 Company Confidential TELEYNE Team Thank you All Company Headquarters: City of Industry, California USA Facility: 60,000 sq. ft. / ISO-9001:2008 Founded: 1945 Core Capabilities: Manufacturer of high quality measurement and control instrumentation. Website: www.teledyne-ai.com