STEEL WIRE MANUFACTURING

Wire drawing is a metalworking process used to reduce the cross-section of a wire by pulling the wire through a single, or series of, drawing die(s)

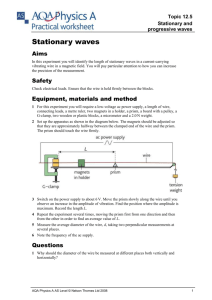

PROCESS OF WIRE DRAWING

Pickling

The wire is pulled through the die, its volume remains the same, so as the diameter decreases, the length increases.

% of areal reduction

Single block wire drawing machines

A bracket standing up to hold the die

A vertical drum which rotates and by coiling the wire around its surface pulls it through the die

The wire drum or "block" is provided with means for rapidly coupling or uncoupling

The block is also tapered

Snatching

Non-circular cross-section drawing

Mechanical Properties

The strength-enhancing effect

Tensile strength can be as high as 3760 MPa

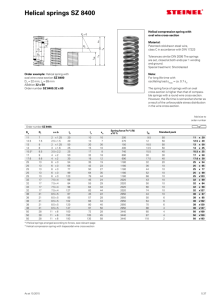

Drawing dies

Tungsten carbide

Die angles usually range from 6–15 °

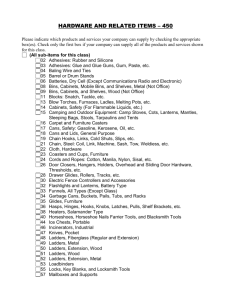

OPTIMIZATION OF OPERATIONS IN A STEEL WIRE

MANUFACTURING COMPANY

Process flow chart :

Wire breakages and maintenance resulted in approximately 60% of the total idle time

Downtime of any one of the KOCH machines will affect the productivity of Bekeart

No specific schedule was prepared for preventive maintenance

The time consumed and the frequency of each fault was not studied

No specific task was taken to change or to revise subassemblies or machine members design which are giving trouble periodically.

Productivity can be increased in numerous ways :

By reducing the input for the same level of output

By increasing the output with the same level of input

By combining both

By reducing down-time due to -

Wire breakages, maintenance, reducing the material input, by using better quality of goods, improved utilization of resources, reduction in working capital

GOAL: NEED TO IMPROVE THE

PRODUCTIVITY

IDLE-TIME ANALYSIS

Shift-to-shift detailed production chart of each machine

Reasoning for idle time occurrence per shift

Wire breakages were basically due to defective raw material, improper pickling and welding

Rare problems – very high time consumption

Regular problems – very less time consumption

The number of arrivals of the entity at the stores.

The number of resources required

Frequency and time of breakdown maintenance of the KOCH machines

Utilization of the KOCH machines

FINDINGS AND CONCLUSIONS

Optimum Lot Size

The objective was to reduce the blocking of the coils in the process

The optimum arrival quantity – 42

Throughput

Increasing the arrival quantity

Adding an extra forklift

FINDINGS AND CONCLUSIONS

Variables

Decision

1

% down,

KOCH1

% down,

KOCH2

% down,

KOCH3

% down,

KOCH4

% Utilization of forklift1

% Utilization of forklift2

6.6

8.6

8.8

9.1

99.9

44.5

2

1.4

2.6

2.8

3.1

100

43.5

3

Scenarios

4

5.7

8.2

8.6

9.1

79.8

99.4

1.8

2.5

3.8

3.4

79.9

99.5

5

1.6

2.5

2.9

3.0

80.0

99.5

Preventive Maintenance