Class 5 Hydraulic Cylinders and Cushioning - UJ

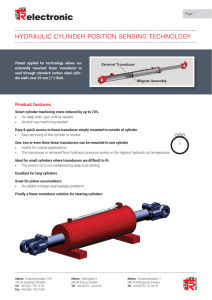

advertisement

Hydraulic Cylinders and Cushioning Devices Introduction Hydraulic cylinders and hydraulic motors perform a function opposite to that performed by a pump. They extract energy from a fluid, and convert it to mechanical energy to perform useful work. Hydraulic System Fxv Hydraulic Cylinder VxI Electric Motor Txω Hydraulic Pump PxQ Hydraulic Motor Txω Introduction Hydraulic cylinders, also called linear actuators provide a force that drives an external load along a straight line. Hydraulic motors, also called rotary actuators, provide a torque that drives an external load along a circular path. Hydraulic System Fxv Hydraulic Cylinder VxI Electric Motor Txω Hydraulic Pump PxQ Hydraulic Motor Txω Hand Operated Hydraulic Jack Telescopic Boom Forklift Airplane Wing Flaps and Landing Gear Telescopic Boom Forklift Airplane Wing Flaps and Landing Gear Single Acting Hydraulic Cylinders Piston Piston Seal Rod Extension Retraction Barrel Port Push Action Oil to extend Return by External Force (e.g. Gravity) Graphic Symbol (P&ID Symbol) Single Acting Hydraulic Cylinders Push Action Oil to extend, Spring for return Pull Action Oil to retract, Spring to extend Double Acting Hydraulic Cylinders Piston Piston Seal Rod Extension Retraction Rod Seal Barrel Port B Port A Oil to extend. Oil for Return Graphic Symbol (P&ID Symbol) Double Ended Piston Rod Double Acting Cylinder Piston Piston Seal Rod Seal Rod Rod Seal Barrel Port A Port B Oil to extend. Oil for Return Graphic Symbol (P&ID Symbol) Cylinder Construction End Cap Tie Rod Threaded Rod Barrel Front Cap Double Acting Hydraulic Cylinders Cylinder Mounting Methods Front Flange Foot Bracket Rear Flange Clevis (Rear Pivot) Side Lug Intermediate Trunnion Cylinder Mounting Methods Front Flange Foot Bracket Direct Rear Screwed Front Clevis (Rear Pivot) Intermediate Trunnion Combining Cylinders with Mechanical Linkages: Oscillatory motion with thrust amplification or reduction First Class Lever Second Class Lever Third Class Lever The three combinations are inverted slider crank mechanisms Combining Cylinders with Mechanical Linkages: Straight line motion with thrust amplification or reduction Thrust Reducer (Six Bar Mechanism) 2:1 Motion Multiplier (Rack and Pinion) Two direction straight line Combining Cylinders with Mechanical Linkages: Continuous Rotary Motion Continuous Rotation (Double Ratchet) Fast Rotary Motion (Screw and Nut) Combining Cylinders with Mechanical Linkages: Motion Transfer Transfer to Distant Point (Pantograph) Cylinder Alignment: Spherical Bushings and Spherical Bearings Much effort has been made by manufacturers of hydraulic cylinders to relieve or eliminate the side loading of cylinders created as a result of misalignment. It is almost impossible to get perfect alignment and since the alignment of the cylinder has a direct bearing on its life, the efforts have been well worth while. A spherical bushing or a spherical bearing is commonly used to deal with misalignment. This approach may not be able to take the loads that the cylinder is capable of producing. It can act as a complete hinge in one direction only, while being limited to a maximum misalignment of five degrees in the other directions. Spherical Bushing Spherical Roller Bearing Cylinder Alignment: Universal Joints A universal joint alignment accessory may be used. It allows fifteen degrees of angular misalignment on each side of center. It also provides more load carrying capabilities. It is recommended that not more than a thirty degree maximum misalignment angle be used on the pins Cylinder Force, Velocity and Power Piston Rod Extension Stroke F ext p Ab v ext Q in Ab P F ext v ext p Q in Retraction Stroke Port Port F ret p Ab Ar v ret Q in Ab Ar P v ret F ret p Q in Ab Ar Cylinder Loading Through 1st class lever As the lever rotates an angle ϴ from its initial orientation, the cylinder rotates an angle фcyl and the load rotates with an angle фload Neglecting friction and dynamic loading (small values compared to forces from the cylinder thrust and load), then taking the moments around the pivot, O, we have M O 0 F cyl L1 cos cyl Fload L 2 cos load F cyl L1 cos cos cyl sin sin cyl 0 Fload L 2 cos cos load sin sin load L1 ϴ For small values of ϴ and фcyl , and фload sin ϴ sin фcyl ≈ 0, and sin ϴ sin фcyl ≈ 0 O Fcyl L 2 cos load L1 cos cyl Fload ϕcyl Assuming no change on the load orientation, фload =0 F cyl L2 L1 cos cyl Fload Fload ϕload F cyl L1 cos cos cyl Fload L 2 cos cos load F cyl L2 Load Displacement Through 1st class lever Assume no change on the orientation of the load, and using the conservation of energy (FcylΔcyl = Fload Δload), we have from the previous equation for small values of ϴ and ф L1 load cyl Fcyl Fload L2 L1 cos L2 ϴ O Fcyl ϕ Fload Cylinder Loading Through 2nd class lever L2 L1 Using the previous assumptions, with no change ϴ O on the load orientation, we have we have Fcyl M O Fload 0 F cyl L1 L 2 cos Fload L 2 cos 0 F cyl L1 L 2 cos cos sin sin Fload L 2 cos For small values of ϴ and ф, sin ϴ sin ф ≈ 0, and Fcyl L1 L 2 cos cos Fload L 2 cos Fcyl Fload lo a d cyl L1 L2 L 2 cos ϕ Cylinder Loading Through 3rd class lever L1 In this case, we have M O ϴ Fcyl F cyl L 2 cos cos sin sin Fload L1 L 2 cos For small values of ϴ and ф, sin ϴ sin ф ≈ 0, and Fcyl L 2 cos cos Fload L1 L 2 cos Fload O 0 F cyl L 2 cos Fload L1 L 2 cos 0 Fcyl L2 lo a d cyl L1 L2 L 2 cos Fload ϕ Buckling and Telescopic Cylinders Buckling occurs when the rod of the cylinder bend or bows sideways under the action of compressive load. The longer and lighter the cylinder rod, the more likely it is for it to buckle. When selecting a cylinder from catalog, it is important to calculate the buckling loads. Telescopic cylinders allow a longer cylinder stroke without buckling. These cylinders have from 2 to five telescopic sections with each section sliding inside a larger section. They are used for lifting platforms, tipping platforms and other commercial vehicle applications. Hydraulic Cylinders Cushions Double acting cylinders sometimes contain cylinder cushions at the end of the cylinder to slow down the piston near the ends of the stroke. This prevents excessive impact when the piston is sopped by the end caps. Deceleration starts when the tapered plunger enters the opening in the cap. This restricts the exhaust flow from the barrel to the ports. During the last portion of the stroke, the oil must exhaust through an adjustable opening Hydraulic Cylinders Cushions The cushion also incorporates a check valve to allow free flow to the barrel during the piston’s reversed stroke. The maximum pressure developed by cushions at the end of the cylinder must be considered, since excessive pressure buildup would rupture the cylinder. Refer to example 6-6 in the book, which illustrates how to calculate this pressure. Hydraulic Shock Absorbers A shock absorber is a multiple orifice hydraulic device. When a moving load strikes the bumper of the shock absorber, it sets the rod piston in motion, which pushes the oil through the a series of holes from the inner, high pressure chamber, to the outer, low pressure chamber. The resistance of the oil flow caused by the holes creates a pressure that acts against the piston to oppose the moving load.