Short Run SPC Presentation - ASQ | Portland Section 0607

advertisement

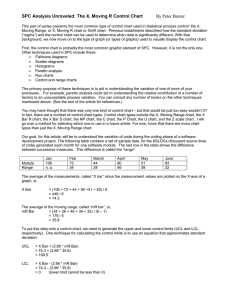

By Ed Landauer, C.Q.E., P.E. November 13, 2012 Short Run SPC What it is What it isn’t SPC is not intended to be a substitute for inspection and testing Programs such as JIT make Short Run SPC more common What Constitutes a Short Run? A run of 25 parts? A run of 100 parts? A run of 1000 parts? A run of 50,000 parts? A single part? General Categories of Short Runs Not enough parts in a single production run to develop or maintain control limits on the process Process cycles are so short that production runs are over before sufficient data can be gathered Many different parts are made for many different customers Examples Example: CNC Machine Extremely complex machine Has dozens of different tools That produce hundreds of different parts With thousands of characteristics Example: CNC Machine- Generic Operations Select a tool Position a tool Rotate a tool Move the part Remove the metal Example: CNC Machine Nearly all problems encountered after the initial set-up involve the ability of the machine to position the tool precisely For example, the location of a single hole provides information on the location of the tool in both the x and y directions Sample Set of Data Twelve subgroups- 3 observations per subgroup 5.0037 5.0009 4.9973 5.9974 6.0021 5.9981 5.0015 5.0023 5.0029 5.9990 5.9983 6.0018 4.9989 4.9981 4.9985 6.0015 5.9977 6.0023 7.0014 6.9991 7.0003 6.0031 5.9987 5.9987 7.0009 6.9979 6.9975 5.9985 6.0011 6.0021 6.9979 6.9995 7.0021 6.0017 6.0021 6.0001 Method 1: Target Average and Range Charts Subtract nominal (or target) value from the actual measurements x* = x - nominal Can plot several parts from a given process on a single chart Can plot several features from a single part on a single chart Method 1: Restrictions Nominal (or target) values must be close to each other with the same tolerance Or the most restrictive tolerance must be used for all Method 1: Control Limits • Calculate averages and ranges of the deviations from target • Control limit formulas are the same as for traditional control charts Method 2: Standardized Variables Control Charts Good for recurring families of parts They are independent of the unit of measure They are scaled so that different characteristics can be plotted on the same chart They are “true” process control charts Method 2: Calculations Use the normalizing transformations Need to use historical averages from previous data in the calculations Method 2: Control Limits X-bar Chart R chart -A2 and A2 D3 and D4 Short Run Attribute Chart- c-chart Job shop welding process Produces small quantities of single order only parts Operation always involves joining parts of similar material and size Can plot chart of weld imperfections per 100 inches of weld Short Run Attribute Chart- p-chart Job shop welding process Similar operation to previous slide Plot chart of the number of weld imperfections per total welds per 100 inches of weld Summary Only minor change in mechanics to move from traditional SPC to Short Run SPC The biggest difference in the perception of Statistical Process Control rather than Statistical Product Control Questions? Thank You! EDL22@comcast.net