w - Politecnico di Bari

advertisement

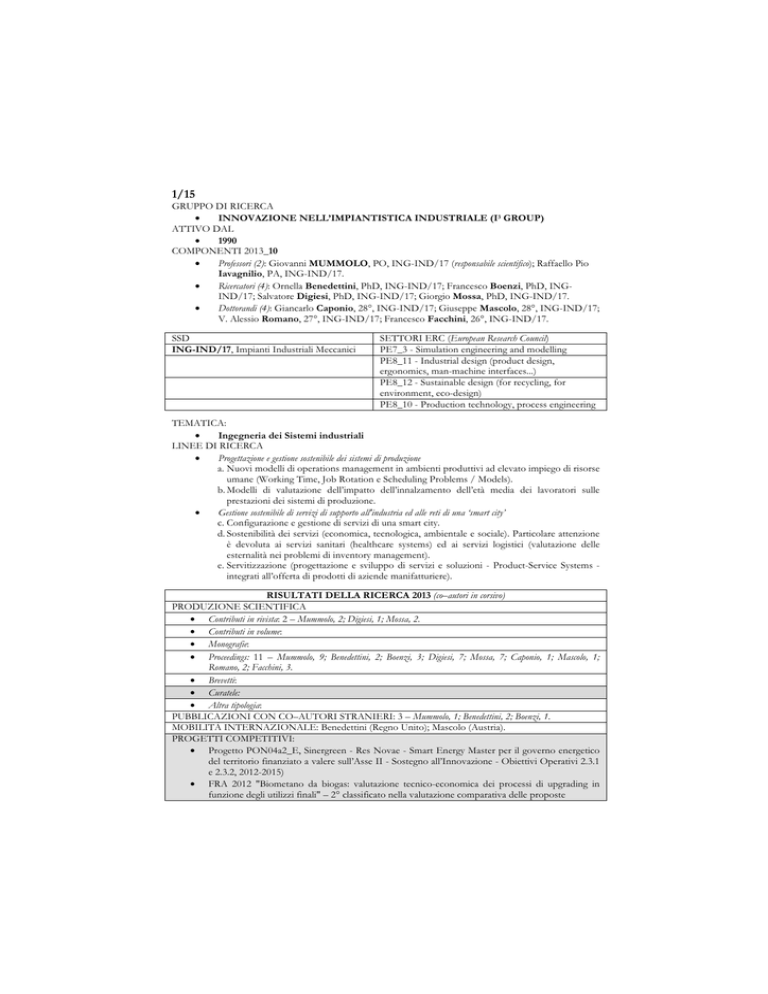

1/15

GRUPPO DI RICERCA

•

INNOVAZIONE NELL’IMPIANTISTICA INDUSTRIALE (I3 GROUP)

ATTIVO DAL

•

1990

COMPONENTI 2013_10

•

Professori (2): Giovanni MUMMOLO, PO, ING-IND/17 (responsabile scientifico); Raffaello Pio

Iavagnilio, PA, ING-IND/17.

•

Ricercatori (4): Ornella Benedettini, PhD, ING-IND/17; Francesco Boenzi, PhD, INGIND/17; Salvatore Digiesi, PhD, ING-IND/17; Giorgio Mossa, PhD, ING-IND/17.

•

Dottorandi (4): Giancarlo Caponio, 28°, ING-IND/17; Giuseppe Mascolo, 28°, ING-IND/17;

V. Alessio Romano, 27°, ING-IND/17; Francesco Facchini, 26°, ING-IND/17.

SSD

ING-IND/17, Impianti Industriali Meccanici

SETTORI ERC (European Research Council)

PE7_3 - Simulation engineering and modelling

PE8_11 - Industrial design (product design,

ergonomics, man-machine interfaces...)

PE8_12 - Sustainable design (for recycling, for

environment, eco-design)

PE8_10 - Production technology, process engineering

TEMATICA:

•

Ingegneria dei Sistemi industriali

LINEE DI RICERCA

•

Progettazione e gestione sostenibile dei sistemi di produzione

a. Nuovi modelli di operations management in ambienti produttivi ad elevato impiego di risorse

umane (Working Time, Job Rotation e Scheduling Problems / Models).

b. Modelli di valutazione dell’impatto dell’innalzamento dell’età media dei lavoratori sulle

prestazioni dei sistemi di produzione.

•

Gestione sostenibile di servizi di supporto all'industria ed alle reti di una ‘smart city’

c. Configurazione e gestione di servizi di una smart city.

d. Sostenibilità dei servizi (economica, tecnologica, ambientale e sociale). Particolare attenzione

è devoluta ai servizi sanitari (healthcare systems) ed ai servizi logistici (valutazione delle

esternalità nei problemi di inventory management).

e. Servitizzazione (progettazione e sviluppo di servizi e soluzioni - Product-Service Systems integrati all’offerta di prodotti di aziende manifatturiere).

RISULTATI DELLA RICERCA 2013 (co–autori in corsivo)

PRODUZIONE SCIENTIFICA

• Contributi in rivista: 2 – Mummolo, 2; Digiesi, 1; Mossa, 2.

• Contributi in volume:

• Monografie:

• Proceedings: 11 – Mummolo, 9; Benedettini, 2; Boenzi, 3; Digiesi, 7; Mossa, 7; Caponio, 1; Mascolo, 1;

Romano, 2; Facchini, 3.

• Brevetti:

• Curatele:

• Altra tipologia:

PUBBLICAZIONI CON CO–AUTORI STRANIERI: 3 – Mummolo, 1; Benedettini, 2; Boenzi, 1.

MOBILITÀ INTERNAZIONALE: Benedettini (Regno Unito); Mascolo (Austria).

PROGETTI COMPETITIVI:

• Progetto PON04a2_E, Sinergreen - Res Novae - Smart Energy Master per il governo energetico

del territorio finanziato a valere sull’Asse II - Sostegno all’Innovazione - Obiettivi Operativi 2.3.1

e 2.3.2, 2012-2015)

• FRA 2012 "Biometano da biogas: valutazione tecnico-economica dei processi di upgrading in

funzione degli utilizzi finali" – 2° classificato nella valutazione comparativa delle proposte

A DSS to minimize Carbon footprint of Integrated

Waste Management System

Francesco Boenzi 1, Salvatore Digiesi1, Giorgio Mossa1, Giovanni Mummolo1,

Rossella Verriello1

Dipartimento di Meccanica, Matematica e Management, Politecnico di Bari, Viale Japigia 182,

Bari, 70126, Italy

{giovanni.mummolo,francesco.boenzi,salvatore.digiesi,giorgio.

mossa]@poliba.it, r.verriello@gmail.com

1

Abstract. The concept of ‘Sustainability’ is increasingly used to describe a paradigm

upon which future policies must be based. In the view of a urban sustainable

development, a strategic role in the governance of the smart City is played by waste

integrated management systems (IWMS). The raising complexity of a IWMS relies

on the high number of design and management variables and relationships related to

collection, treatments and disposal phases. Waste management practices can affect

greenhouse gas emission by influencing energy consumption, methane generation,

carbon sequestration and non-energy related manufacturing emission. A decision

support system can be modelled aiming to evaluate and minimize the carbon

footprint of a IWMS. The model proposed goes beyond the existing technical and

organizational solutions outlining the different options in a much broader view

concerning both waste collection and treatments.

Keywords: Integrated Waste Management System, Sustainability, Carbon footprint,

Smart city, Decision Support System

1

Introduction

Industrial and societal challenges are mutual dependent and provide significant

impacts on the grand challenges of the EU 2020 strategy: reduction of 20% of GHG

emission, the achievement of 20% energy demand by renewable energy together with

an increase of 20% of energy efficiency [1]. The challenge is considerable since cities

are responsible for about 70% of the overall primary energy consumption and for as

much as 80% of global Greenhouse Gas (GHG) emissions [2]. A wide literature is

available on methods and experience to tackle urban greenhouse gas emissions [3], [4].

In the 2020 European strategies, the innovation of the city is identified as the starting

point towards the ambitious path to sustainability at regional level. Making "smart"

cities means undertake coordinated set of interventions that aim to make cities more

sustainable primarily from the point of view of energy and environment, through

choices and technologies that save energy, use of renewable energy in both the public

in the private sector. The Strategic Energy Technology Plan (SET Plan) identifies the

smart cities as one of the seven priorities for investment by allocating a huge sum to

“Smart City Industrial Initiative” [5]. In the view of a urban sustainable development,

a strategic role in the governance of the City is played by integrated waste

management systems. The waste sector has experienced a decrease in emissions of

greenhouse gases rising from 204 million tons in 1990 to 133 million tonnes in 2011

[6]. Due to the rapid population growth and the rapid expanding of urbanized areas

as well as to changes in human activities and lifestyles, nowadays IWMS plays a key

role at city level. Integrated solid waste management reflects the need to approach

solid waste in a comprehensive manner with careful selection and sustained

application of appropriate technology, working conditions, and establishment a

‘social license’ between the community and designated waste management authorities.

The aim of the research project is to develop a Decision Support Systems (DSS) for

more sustainable Integrated Waste Management Systems focusing on the:

- Definition of a reference framework to support public decision-makers in designing

and planning the Integrated Waste Management Systems (IWMS).

- Definition of a Tool for optimizing and monitoring the carbon footprint of IWMS.

2

Study Methodology

A systematic and holistic approach is required to tackle the complexity and ensure

transparency and repeatability of decision making process. The authors propose a

Reference Framework for Planning a Municipal Waste Integrated Management

System to jointly:

design and plan the integrated waste management system;

estimate and minimize the net emission due to the entire cycle.

On the basis of the mathematical model adopted in [7] for optimizing collection

phase, a model including also the treatments phase is proposed in [9]. The dry

fractions collected are sent to the selection facilities that could have a different level

of automation. Innovative technologies are promising high performance in terms of

costs reduction, low environmental impacts and high and constant quality of waste

to be recycled. After an appropriate pretreatment, the organic fraction is usually sent

to an anaerobic digestion to recovery materials and biogas/bio-methane having

different possible utilizations. Mechanical-biological treatment is required by nonrecycled fraction before the thermal recovery. The gasification process is modelled

according to [8]. The logical structure of the problem suggests the formulation of a

Mixed Integer Nonlinear Programming (MINLP) problem to support decision

makers in finding out the integrated waste systems with the lowest carbon-footprint.

Table 1. Notation adopted in the model

Symbol

k

i

j

w

feji

W

Pj,i

Description

Waste fractions k = 1: organic; k = 2: glass; k = 3: paper; k = 4: plastics, metal cans

Grouping Systems i =1: ‘single stream’; i = 2: ‘multi stream’;

Collection Systems j = 1door-to-door’;j = 2‘aggregate’; j = 3‘proximity’;j= 4‘street’;

Stages of IWMS; w=1 sorting; w=2 selection&sorting; w=3 organic pretreatments;

w=4anaerobic digestion; w=5 composting; w=6 Tmb.

Emission factor of the transport mean to collect waste fraction according to

the i-th grouping and the j-th collection system

Number of weeks in the observation period

Number of picking operations of unit loads for i-th stream grouping and the

j-th collection system

Number of work-shifts per day

Average speed of the transport mean adopted by the j-th collection system

Production per capita of urban waste

collecting efficiency of the k-th material collected by the j-th waste collection

system according to the i-th waste stream grouping;

percentage of the k-th type of waste in the total solid waste produced.

average number of members in a family

bin load capacity

Total amount waste produced

Waste produced by commercial users

Efficiency of w-th stage for the k-th waste fraction. Skw=1- ekw

Electricity emission factor measured as tCO2eq/Kwh

Emission factor of w-th stage for the k-th fraction measured as tCO2eq/twaste

Activity data [Kwh/ton]

Energy from recovery of waste (from biogas and syngas)

Avoided emission from recovery and prevented disposal

Organic flow after TMB send to landfill (%)

Maximum annual amount treated by anaerobic digestor and TMB

Emission factor for disposal respectively dry fraction and organic fraction

H

vj

Pc

ɳkji

Pk

c

Bj

Glob.waste

XCom.k.waste

ekw

EFel

EFkw

actw

Ek

Fk

OTMB

XMax

EFl1 -EFl2

The decision variables are

• Ni,k : boolean variable to infer if the j-th grouping system is adopted;

• Nj,I,k,: number of users served by the j-th collection system and the i-th waste

stream grouping for the k-th waste fraction;

• nwj,i,k: weekly collection frequency of the k-th fraction, by the j-th system

according to the i-th waste stream grouping;

with X k =

( p c p nw

c

k

jik

N ik N jik

)

and X ' k = X k + XCom.kwaste .

The objective function is:

Min EmColl + EmTreat + EmTMB + EmLand + EmEn.Re covery + EmAvoidedLand

(

where:

(

EmCol = ∑ ∑ ∑ H ⋅ v jW feji nw jik N ik N jik / B j ⋅ Pji

k

i

2

j

4

),

)

4

w−1

EmTreat = ∑ ∑ (X k' ∏ ek,w−1EFk,w ) + ∑ (X1'EF1,w e1,w )

w=1 k=2

w=1

w=3

EmTMB = ( Globwaste − ∑ X ) act w EFel

'

k

k

2

4

5

EmLand = (∑ ∑ (X k' Sk,w EFl1 ) + ( Globwaste − ∑ X k' ) OTMB EFl 2 + ∑ (X1'S1,w )EFl 2

w=1 k=2

k

EmEn.recovery = Ek EFel

4

2

k=2

w=1

EmAvoidedLand = ∑ X k' (1- ∑ Sk,w )EFk

The function is subjected to the following constraints:

w=3

∑ Nik = 1

, ∀k

i

N 2,1 = 0 ∧ N 2,2 = 0 ; N i,3 = N i,4

∑ ∑ Nik N jik = N

i

TOT

,∀k

j

N jik ≤ N jMAX ∧ N jik ≥ N jMIN ,∀j,i,k

N1,2,1 = N 2,1,2 ∧ N 3,1,2 ≥ 0 ∧ N 4,1,2 ≥ 0

N j,2.3 = N j,2.3 ,∀j

nw jik ≥ nw jikMIN ∧ nw jik ≤ nw jikMAX ,∀j,i,k

∑ ∑ ∑ (p

c

i

j

⋅ c ⋅ pk nw jik N ik N jikη jik ) ≥ SC MIN

k

X 'k ≤ X MAX

Readers could refer to [3] and to [5] for a more detailed description of the model.

3

Preliminary results and future developments

The developed framework is applied to a full case study referring to the municipality

of Bari. The model suggests the adoption of a multi stream grouping system for the

dry recycled fraction and single stream grouping system for organic and glass fraction.

Fig.1: Percentage of users served by the j-th collection system in case of optimization of (i)

only collection phase and (ii) of the whole IWMS.

As one can see in Fig.1, in case of optimization of IWMS(ii) solution obtained

privileges the DTD and Aggregate collection system for organic and dry recycled

fraction, keeping as much low as possible (see upper and lower limits in [7], [9]).For

the glass fraction the model solution suggests, in both case, the collection to be

carried out by the Proximity system meanwhile the Street system is limited at the

minimum values. Details of emission are listed in Table 2.

Table 2: Emission of the Integrated waste Management System

Source Emission

Collection

Sorting facilities

Selection facilities

Anaerobic digestion

Mechanical biological Treatment

tCO2eq/y

1,010

822.0

167.0

714.0

433.0

Landfill

Avoided by recovery materials

Avoided by energy recovery of biogas

Avoided by energy recovery of syngas

Total [tCO2eq/y]

4

24,303.0

-50044.0

-1614.0

-1742.0

-­‐25,952.0

Conclusions

Results obtained outline that the single-stream grouping system has to be adopted for

organic and glass fraction. Differently, the model suggests the adoption of a multistream grouping system for dry recycled fraction; such a grouping system allows for a

reduction in the number of collection cycles resulting in a reduction of GHG

emissions. Collection system with higher efficiency values even though responsible of

higher collection emission reveals to be optimal choices. The reason for this lies in

the right valorization of the waste. The benefits of energy recovery and the avoided

disposal of waste fraction negative emissions) offset both the collection and

treatments emissions (positive emissions). Further research will consider the

economics aspects of the IWMS, as well as the jointly impacts of the environmental

and economic issues on the model. Furthermore, the research project will lead to a

dynamic design and plan of all the phases of the IWMS.

Acknowledgements. The paper has been written within the framework of the project PON04a2_E

“Smart Energy Master per il governo energetico del territorio - SINERGREEN - RES NOVAE”. The

project is supported by the Italian University and Research National Ministry research and competitiveness

program that Italy is developing to promote “Smart Cities Communities and Social Innovation”.

References

[1] Mummolo, G., (2014). Looking at the Future of Industrial Engineering in Europe. In: Hernández

Iglesias, Cesáreo; López-Paredes, Adolfo; Pérez Ríos, José M. (Eds.). Managing Complexity: Challenges for

Industrial Engineering and Operations Management. Lecture Notes In Management And Industrial

Engineering, vol. N. 2, Springer, ISBN: 978-3-319-04704-1.

[2] International Energy Agency (IEA), http://www.iea.org/topics/climatechange.

[3] Blackhurst, M., Scott Matthews, H., Sharrard, A. L., Hendrickson, C.T., & Azevedo, I.L. (2011).

Preparing US community greenhouse gas inventories for climate action plans. Environmental Research Letters,

6.

[4] Dhakal, S. (2010), GHG emissions from urbanization and opportunities for urban carbon mitigation.

Current Opinion in Environmental Sustainability, 2(4), pp. 277–283.

[5] SETPLAN europeo: http://ec.europa.eu/energy/technology/set_plan/set_plan_en.htm; Technology

Roadmap: http://eurlex.europa.eu/LexUriServ.

[6] Eurostat, (2013). Smarter, greener, more inclusive Indicators to support the Europe 2020 strategy.

http://epp.eurostat.ec.europa.eu/cache/ITY_OFFPUB/KS-02-13-238/EN/KS-02-13-238-EN.PDF

[Accessed: Dec 2013].

[7] Caponio G., D'Alessandro G., Digiesi S., Mossa G., Mummolo G., Verriello R. Minimizing Carbonfootprint of Municipal Waste Separate Collection Systems. Lecture Notes in Management and Industrial

Engineering - Springer series. [in press – 2014].

[8] Jarunngthammachote, S., Dutta, (2007)A. Thermodynamic equilibrium model and second low analysis

of a downcraft gasifier, Energy, Vol.32, pp.1660-1669

[9] Digiesi S., Mossa, G., Mummolo, G., Verriello, R.., Minimizing Carbon- footprint of Municipal Waste

Integrated Management Systems In Proceedings of The XIX Summer School “Francesco Turco”.

Senigallia (AN). September 9-12 2014.