Portable Power Tools - Biosystems and Agricultural Engineering

Portable Power Tools

Unit 14

Page 180

1

Introduction

• Portable Power Tool: A tool that can be held in the operators hands, but is not hand powered.

• Four common sources of power.

Battery

Electricity

Pneumatic

There are advantages and disadvantages for each type of power source.

Engine

2

1. Electrical Power

• Very popular

• Usually use 120 V, 1ø power

Disadvantages

– Must stay connected to power cord.

– Hazards of electricity

Advantages

– Unlimited power

– Many different types of tools.

Extension cord must be proper size and in good condition.

3

2. Pneumatic

Becoming more popular where compressed air is available.

Advantages

– Smaller dimensions for torque produced

– Torque easily adjusted

(changing pressure)

– Popular in hazardous environments

Disadvantages

• Air must be clean and dry.

• A blast of high pressure air can embed objects in the skin or eyes.

• Air hose more difficult to manage than electric cord.

All common tools can be air driven.

– Drills

– Ratchet drives

– Sanders

4

3. Battery

New technology in batteries has made battery powered tools the first choice for most professionals.

Advantages

– Portability

– Sealed unit

– No electrical circuit hazards.

– Can be used with a wider variety of tools when compared to pneumatic.

Disadvantages

– May be less torque

– Must have a charged battery to use.

– Batteries can have a short useable life and are expensive to replace.

5

4. Engine

Popularity is gaining with the resent invention of lighter weigh engines.

The elimination of 2-cycle engines will require a redesign.

Advantages

Portability

No air hose

No extension cords

No battery

Disadvantages

– Must be used in open environment.

– Disadvantage of engine maintenance.

– Safety concerns of gas engines.

– Usually only large sizes.

6

Portable Power Tool Safety

• Use GFCI protected circuit.

• Use three-wire electrical source if tool housing is metal or partially metal and not double insulated.

• Insure blades, bits, and other cutting devices are clean and sharp

• Support work carefully

• Keep all tools clean and free of dirt.

• Keep tool vent holes clean.

• Wear appropriate personal protection

• Avoid or use extra care when working in wet areas

• Do not force tools to work.

• Hold power tool firmly and insure your have control at all times.

• If the condition of the tool is in doubt, do not use.

• Announce to co-workers before starting a tool.

• Lay tool down correctly

• Take any faulty tools out of use and insure they are fixed before returning.

7

Nail Guns

• Popular because they are fast and efficient.

– Produce enough force to drive 2 - 3 inch nail into dense wood.

– Accelerate nail to 1,000 feet per second.

• Four types

– Brad

– Framing

– Finishing

– Staple

• Power

– Pneumatic

– Electric

– Fuel cell

• Fasteners

– 1/4 inch brad and staples up to 4 inch nails.

8

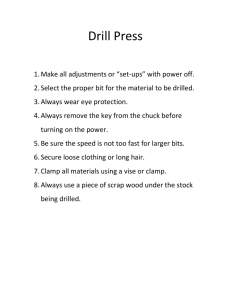

Portable Drills

• Size

– Size based on capacity of chuck

– Wattage difference within chuck size

– Common sizes are 1/4, 3/8, 1/2 &

3/4 inch

• Construction

– Case will be metal, non-metallic or a combination.

– Wide variety

• Options

– Variable speed

– Reversing

– Extra handle

– Hammer action

– Torque clutch

– Depth stop

– Drill press attachment

– Keyless chuck

– Screw chuck

9

Portable Drill-cont.

• Use many different types of bits.,

• Drill holes and slots

• Use to drive screws

• Sanding disc and wire wheels can be used.

– Must be careful to not exceed the duty cycle

Always center punch location of hole.

Drill pilot hole before using a large drill bit.

10

Portable Drill Safety

• Inspect bit before using

• Tight chuck using more that one hole

• Center punch metal before starting to drill

• Hold material securely

• Do not exceed rpm of bit

• Use even pressure

• Ease off pressure when drill starts to break through

• Don’t bind the drill bit

• Stand in a balanced position

• Remove the drill from the chuck when finished

• Store portable drill and bits in case or designated storage rack.

11

• Three common types

– Belt

– Disc

– Pad

Sander

12

Sander-cont.

• Portable power sanders to the same job as hand sanding--just faster.

• Normally sand with the grain

• Exceptions

– Uneven boards

– Rough surface

– Removing difficult finishes

• Different grit paper available

– Coarse grit = rapid sanding, rough surface

– Fine grit = slow sanding, smooth surface

13

Belt Sander

• Very versatile

Popular for rough sanding because of aggressive action with coarse belts.

Can produce smooth finish with fine belt.

• Some belts are not bidirectional.

• Dust collection system highly recommenced.

14

Belt Sander Safety

• Wear appropriate PPE

• Check cords and switches

• Install appropriate belt for the desired cutting action and finish

• Lay sander on side when not in use

• Empty dust bag frequently

• Always start sander above the surface

• Use two hands at all times

• Keep machine in motion

• Lift off material while still running

• Never sand on the drums

15

Disc Sander

• Machine can use sanding disc, grinding wheel and wire brush interchangeably.

• Must follow manufacturer's recommendation for use.

Motor Housing

Tool Rest

Sanding

Wheel

Switch Lock

Sanding

Disc

Power Cord

Handle

Vents

Handle

Switch

Guard

• Several tools with this right angle design look the same.

• Some are sanders, some are sanders/grinders and some are grinders.

• Big difference in construction

• Grinders are much heavier construction.

16

Disc Sander Safety

• Select the sanding wheel appropriate for the material being sanded.

– Aluminum oxide = wood or metal

– Flint paper = wood only

• Use the appropriate guard

• Wear appropriate PPE.

• Grip machine firmly in both hands before starting

• Do not force the machine to work

• Lay the machine on the tool rest, not the disc.

• Be aware of, and plan for the direction of material being discharged by the wheel.

• Hold small pieces in a vise.

17

Disc Grinder Safety

• Wear face shield plus safety glasses.

• Check grinding wheel for cracks before using

• Only use wheel designed for that machine.

• Never use grinding wheel that is less than 1/2 original diameter.

• Secure small pieces in a vise

• Do grind near combustibles

• Hold the machine with both hands at all times.

• Always be aware of were the discharged sparks and grit is going.

18

Motor Housing

Handle

Pad (Finishing) Sander

Switch Lock Handle

Power

Cord

Paper

Clamp

Sand

Paper

• Multiple pad movements possible.

– Reciprocating

– Circular

– Orbital

– Random

• Slower cutting

Switch

Paper

Clamp

Pad

19

Pad Sander Safety

• Use appropriate PPE.

• Use correct size of paper.

• Disconnect power when changing paper.

• Only use light pressure when sanding

20

Portable Saws

• Portable saws can be divided into three categories.

– Sabre

– Reciprocating

– Circular

21

Switch

Blade

Retention

Screw

Toe

Blade

Sabre Saws

Handle

Power

Cord

Motor

Housing

Base Tilt

Lock

Base

• A compact saw that is very useful for cutting curves.

• Designed for wood, but will cut thin metal.

• Blade uses reciprocating motion.

• Can be used for blind cuts.

• Base may tilt for cutting bevels.

22

Sabre Saw Safety

• Wear appropriate PPE

• Select correct blade for job.

– Width of blade determines minimum radius

• Secure material being cut

• Let saw determine feed rate.

• Must maintain downward pressure on the saw when cutting.

23

Reciprocating Saw

• Usually heavier duty that the sabre saw.

• Longer stroke on the blade.

• Many different types of blades.

• Designed for wood and metal.

Shoe

Blade

Motor Housing

Blade

Retention

Screw

• Does not cut as precise as sabre saw.

• May be multiple speed.

• Can be used to make a blind cut.

• Very popular for demolition work.

Switch

Switch

Lock

Handle

Cord

Vents

24

Reciprocating Saw Safety

• Wear appropriate PPE.

• Select the correct blade for the job.

• Select the correct speed.

• Be careful not to bind, pinch or crowd the blade.

• Hold the shoe against the work at all times.

• Do not wear loose fitting clothing.

25

Circular Saw

• Most popular saw for carpentry work.

• Different size and types of blades are available.

• Can be used for wood and metal.

• Available in direct mount, right and left hand and worm drive.

26

Circular Saw Safety

• Wear appropriate PPE.

• Use face shield + safety glasses

• Use blade appropriate for work.

• Support work correctly.

• Disconnect the power when adjusting the saw.

• Adjust blade for depth so that only 1/4 inch or the depth of one tooth extends through the work.

• Hold saw in both hands.

• Start the saw before contacting work.

• If the saw stalls, back out of kerf.

• Watch the line ahead of the saw.

• Near the end of the cut reduce the pressure.

• For ripping use the ripping guide attachment or clamp a straight edge to the work.

27

Circular Saw Capacity

• Capacity of portable circular saws at 45 degree bevel and straight.

BLADE DIAMETER CAPACITY 45 o

4 1/2

6 1/2

6 3/4

7 1/4

7 1/2

8 1/4

10 1/4

12

1 1/16

1 5/8

1 3/4

1 7/8

2 1/16

2 1/4

2 3/4

3 5/16

CAPACITY 90 o

1 5/16

2 1/16

2 7/32

2 3/8

2 17/32

2 15/16

3 5/8

4 3/8

28

Router

• Routers are used for specialized jobs such as ornamental shapes, rabbets, dadoes, hinges, etc.

• Router bits turn at high speeds.

• May have several attachments.

• Must use guide to complete straight cuts.

• May be mounted on a table.

Cord

Switch

Depth of Cut

Adjustment

Depth of cut

Scale

Handle

Collet

Base

29

Router Safety

• Wear appropriate PPE.

• Secure work.

• Insure router is unplugged before installing bit or setting depth adjustment.

• Always inspect bit for condition and sharpness.

• Install the appropriate bit.

• Insure bit shank is fully inserted into collet.

• Carefully set depth of cut.

• Set base squarely on work.

• Always use both handles

• Feed router into work at correct speed.

30

Questions

31