PPT

advertisement

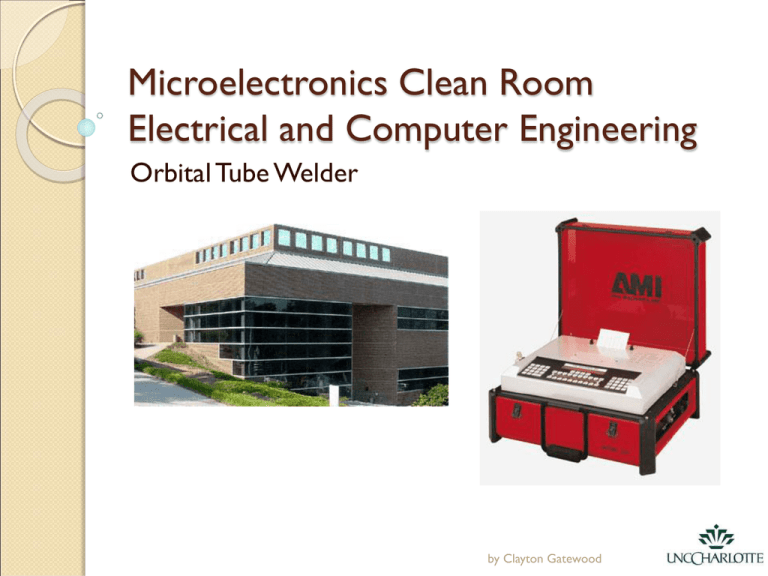

Microelectronics Clean Room Electrical and Computer Engineering Orbital Tube Welder by Clayton Gatewood Overview General Information Safety Set-up Tube Preparation: facing, cleaning Operation Weld Schedules Weld Evaluation by Clayton Gatewood Orbital Tube Welding Gas Tungsten Arc Welding (GTAW) process Fusion Welding Model 8 Weld Head Model 207A Power Supply Argon Gas Cylinder Facing Tool ARC Machines, Inc. by Clayton Gatewood Gas Tungsten Arc Welding (GTAW) Process Used to weld tubing that remains in-place while the tungsten electrode rotates around the target joint. Material edges are heated by an arc and are fused together without a filler. by Clayton Gatewood Safety Electricity Hazard: Shock, RF Starting, Pacemaker, Electric Storage Devices Fire Hazard: Clothing, Sealed Containers, Welded Material Hot to Touch Harmful UV Radiation (eyes and skin) Toxic Fumes from Welding Stainless Steel, Hexavalent Chromium (lung cancer) Air Displacement by Argon Gas Factory Training Essential Keep Hands and Fingers Clear Compressed Gas Cylinders Cleaning Chemicals by Clayton Gatewood Set-Up Ensure Power is Off Connections: Weld Head, Argon Gas, main power cord Apply Argon (¼ turn) @ 20 psi by Clayton Gatewood Tube Preparation Facing by Clayton Gatewood Welding Cleanliness Materials to be welded must be free of grease, oil, rust, dirt, paint and other contaminants. Dirty materials can result in porosity, discoloration, slag deposits, and generally poor quality welds. by Clayton Gatewood Operation Align target joint with tungsten electrode Connect Argon Purge Line and set for 5 psi (for ¼” OD tubing) Select Weld Schedule Ensure Power Supply is “Ready to Weld” Press “Seq Start” Prepurge, Weld, Downslope, Postpurge by Clayton Gatewood Weld Schedule Development An orbital tube weld may be done in 4 or more levels. It must include enough time for tiein before the downslope. by Clayton Gatewood Weld Schedules Pre / Post Purge Time Up / Downslope Rotation Direction Rotation Delay Pulse Mode Rotation Mode RPM (Rotor Travel Speed) Level Times Level Amps Background Amps Pulse Times by Clayton Gatewood Power Supply Sequence by Clayton Gatewood Sample Weld Schedules by Clayton Gatewood Weld Evaluation 60 to 80% overlap on outer diameter Poor rotation delay Borescope to inspect inner diameter Full penetration No cracks, undercut, crevices, pits, or embedded or protruding material by Clayton Gatewood Weld Profiles by Clayton Gatewood Weld Defects Weld Problem Probable cause(s) Lack of penetration to I.D. 1) Insufficient amperage 2) Tungsten offset 3) Change of heat number 4) Sulfur mismatch 5) Variable wall thickness 1) Too much amperage 2) Gravity (heavy wall) 3) Very low sulfur 1) Excessive ID purge pressure OD Concavity ID Concavity Discoloration of ID (oxidation) Misalignment Porosity Excessive slagging 1) Excessive oxygen and/or moisture in ID purge gas 2) Moisture and/or oxygen in or on tubing 3) Chemical residue from EP 4) Leak in purging set up 5) Pinched gas hose 1) Dimensional tolerances - out of round 2) Wall thickness mismatch 3) Worn out TCIs 4) Poor workmanship 1) Moisture in purge gas 2) Moisture or dirt on weld components 1) impurities in base material especially oxides of aluminum, calcium, silicon by Clayton Gatewood Argon Purge and Oxygen Left to Right = effect of increasing levels of oxygen in the argon purge by Clayton Gatewood Possibilities … by Clayton Gatewood Works Cited "MODEL 207 Operator Training Guidelines." Arc Machines, Inc.CD-ROM.Pacoima, CA: Arc Machines, Inc., 2007. Model 207 Microprocessor-Controlled Power Supply.1 Nov. 1996. Arc Machines, Inc.. 16 Oct. 2007.<http://www.arcmachines.com/prodMed/m2 07ps/m207ps.html>. by Clayton Gatewood