Subpart F Fire Protection and Prevention

advertisement

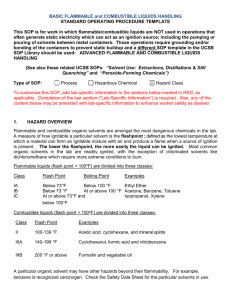

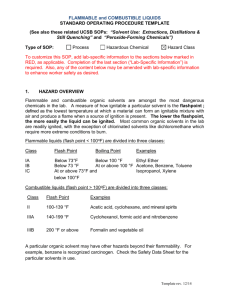

Fire Protection and Prevention These handouts and documents with attachments are not final, complete, or definitive instruments. This information is for guidance purposes only. You should independently verify and satisfy yourself as to its accuracy. The AHBSIF does not assume any liability for damages arising from the use of this information or exhibits and attachments thereto and renders no opinion that any of the terms, conditions, and/or cited federal standards in this document and the exhibits and attachments should be explicitly followed by the fund member. Seek specific guidance from the appropriate regulator (OSHA) or professional advisor. Fire Terms Defined • Conduction – Heat transfer by direct contact • Convection – Heat transfer by an intermediate source (air, gas, liquid) • Radiation – Energy traveling through space similar to a wave (light, radio, x-rays) • Flash Point – The temperature at which a liquid gives off ignitable vapors • Ignition Temperature – The temperature at which a substance ignites Fire Basics See Appendix “B” • Components of combustion Oxygen – Oxygen – sustains combustion – Heat – raises the material to the ignition temperature Heat – Fuel – combustible material – Chemical Reaction – exothermic release • Suppression of any one of these components stops the fire Fuel Chemical Reaction Products of Combustion fire Thermal Products Flame Heat Non-Thermal Products Smoke Gases Signage • Flammable and Combustible Liquids – Storage cabinet where flammable and combustible liquids are stored must be conspicuously labeled • Spray Finishing – “NO SMOKING” – All spraying areas and paint storage rooms • Extinguishers – Location of extinguishers shall be labeled so location is easily identifiable • Personal Protective Equipment – For processes that require specific protective equipment Signage • Exit Routes – Each exit must be clearly visible and marked – “EXIT” must be legible and no less than six inches high and three quarters of an inch wide • Hazardous Material Storage – Location must be fenced and posted to prevent entrance from unauthorized personnel • Electrical – Breaker panel must display manufacturer’s name, trademark, or other descriptive identification – Must provide voltage, current, wattage, and other ratings – Labels must withstand the environment – All breaker switches inside the panel must be labeled Material Storage • Combustible scrap, debris, and waste materials (oily rags, etc.) should be stored and removed from the worksite as promptly as possible • Proper storage practiced to minimize the risk of fire including spontaneous combustion • Keep combustible materials away from potential ignition sources • Never store flammable or combustible liquids in access or egress areas Flammable Liquid Classification Flammable Liquid refers to any liquid having a flash point below 100° F FP - Flash Point BP - Boiling Point Class IA Class IB Class IC FP < 73° FP < 73° FP ≥ 73° BP < 100° BP ≥ 100° BP < 100° Combustible Liquid Classification Combustible Liquid refers to any liquid having a flash at or above 100° F FP - Flash Point Class II Class IIIA Class IIIB FP ≥ 100° FP ≥ 140° FP ≥ 200° FP < 140° FP < 200° Flammable and Combustible Liquids • The quantity of flammable or combustible liquid that may kept outside of a storage room or cabinet inside the building shall not exceed: – 25 gallons of Class IA liquids in containers – 120 gallons of Class IB, IC, II, III liquids in containers – 660 gallons of Class IB, IC, II, III liquids in a single portable tank Inside Storage Rooms • Shall be of fire resistant construction • Liquid tight were the walls join the floor • Have approved self closing doors at all openings • At least 4” sills, ramps, or depressed floors or open integrated trench which drains to safe location Inside Storage Rooms • A ventilation system that provides at least six room changes / hour • For Class I liquids, electrical wiring approved for hazardous locations • Explosion resistant lighting fixtures • Wood at least 1 inch nominal thickness for shelving, racks, dunnage, scuffboards, floor overlay, and similar installations Flammable Storage • All solvent wastes and flammable liquids must be kept in fire-resistant, covered containers until they are removed from the worksite • Firm separation should be placed between containers of combustibles or flammables, when stacked one upon another, to assure their support and stability • Permanently installed sprinkler system heads must not spray into operating electrical switch boards or equipment Flammable Liquids • Spills of flammable or combustible liquids must be cleaned up promptly • Storage tanks must be adequately vented to prevent the development of excessive vacuum or pressure as a result of filling, emptying, or atmosphere temperature changes • Storage tanks must also be equipped with emergency venting that will relieve excessive internal pressure caused by fire exposure • Insure that all connections on drums and combustible liquid piping and vapor are liquid tight Flammable Liquids • Use compliant metal safety cans for handling of any flammable liquids in quantity greater than a gallon • Keep flammable liquids in closed containers when not in use (example: parts cleaning tanks, pans, etc.) • Ground and bond bulk drums of flammable liquids to containers during dispensing Flammable Liquids • Spills of flammable or combustible liquids must be cleaned up promptly • Storage tanks must be adequately vented to prevent the development of excessive vacuum or pressure as a result of filling, emptying, or atmosphere temperature changes • Storage tanks must also be equipped with emergency venting that will relieve excessive internal pressure caused by fire exposure Compressed Gas Cylinders Cylinder valves must be protected at all times Cylinders should be stored in an upright and secure position The tilt and roll method is accepted practice for movement, never attempt to hoist with chokers Valve caps must be secure any time the cylinder is not in use When stored, compressed cylinders should be segregated. The required separation is 20’ or a five foot high fire wall with an approved fire-resistance rating Welding-Cutting-Burning Extinguishing equipment should be located in an obvious place and be easy to reach Remove all flammable materials within a 35 ft radius Remove all combustible materials within a 50 ft radius Remove all explosive materials within a 100 ft radius Housekeeping Potential sources of fire on the jobsite due to poor housekeeping Scrap lumber piles Discarded Building materials Flammable liquid/chemical spills Trash Reactive chemicals Unprotected cords in traffic areas Protection Measures • Develop a system to alert employees in the event of a fire • Alternate extinguishment systems are acceptable; water drums, hoses, smothering agents • Easiest means is to provide at least one extinguisher per house • make sure employees know extinguisher location • Train workers on proper extinguisher operation Fire Extinguishers • Fire extinguishers must be selected and provided for the types of materials in areas where they are to be used – Class A, Ordinary combustible material fires. – Class B, Flammable liquid, gas or grease fires. – Class C, Energized-electrical equipment fires. • Fire extinguishers should be mounted within 75 feet of outside areas containing flammable liquids, and within 10 feet of any inside storage area for such materials • Access to extinguishers should be free from obstructions or blockage • Fire extinguishers must be serviced, maintained, and tagged at least once a year Fire Extinguishers Ordinary Combustibles Includes materials such as wood and paper Flammable Liquids Includes fuels, grease, other liquids Electrical Fires Contains non-conductive smothering agent Fire Extinguisher Inspection • Body of the extinguisher; rust, cracks, dents • Check hose for cracks, dry-rot • All fittings snug, no signs of leaks • Lever and hinge assembly • Safety pin in place, safety tie present • Inspection tag, present and up to date • Pressure gauge, needle in the green How to Use a Fire Extinguisher P-A-S-S Pull -- Pull the pin at the top of the extinguisher that keeps the handle from being activated Aim -- Aim the nozzle at the base of the fire Squeeze -- Maintain a distance of eight to ten feet away from the fire and squeeze the handle. Discharge will only occur if the handle is being squeezed. Sweep -- Sweep the nozzle back and forth at the base of the fire until it appears to be out. On-site Burning • When burning trash on site be aware of all surrounding factors; – – – – – Local Burning restrictions Wind direction Proximity to structures Materials to be burned Means for extinguishment if things get out of control