1 billion

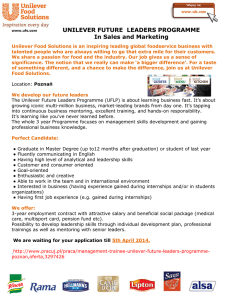

advertisement

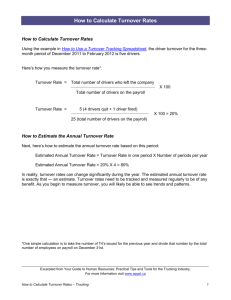

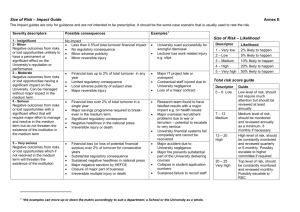

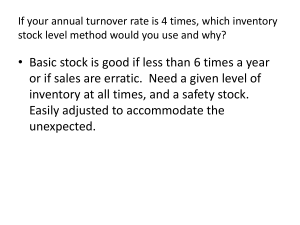

UNILEVER END 2 END SUPPLY CHAIN LULEÅ OKTOBER 2013 KHALIL EL-ACHKAR NORDIC QUALITY ASSURANCE MANAGER UNILEVER HISTORY Margarine Unie (Netherlands) Lever Brothers (UK) 1930 Unilever NV (Netherlands) Unilever PLC (UK) FAST FACTS - 2012 252 FACTORIES (4 IN NORDICS) COUNTRIES IN WHICH OUR PRODUCTS ARE SOLD TURNOVER OF €51 BILLION AT END OF 2012 173,000 EMPLOYEES AT THE END OF THE YEAR €1 BILLION INVESTED IN R&D WORLDWIDE 190 SCALE AND GEOGRAPHICAL REACH EUROPE THE AMERICAS €17.1 billion turnover 3.1% underlying volume growth 33% of group turnover EUROPE EUROPE €13.9 billion turnover 0.9% underlying volume growth 27% of group turnover EUROPE ASIA, AFRICA, CENTRAL & EASTERN EUROPE €20.4 billion turnover 5.7% underlying volume growth 40% of group turnover CATEGORY HIGHLIGHTS IN 2012 FOODS Turnover: €14.4 billion HOMECARE Turnover: €9.1 billion PERSONAL CARE Turnover: €18.1 billion REFRESHMENT Turnover: €9.7 billion LET’S START WITH A SHOP VISIT What is End 2 End Supply chain? More than delivering on time in full… DELIVER Perfect store Product – Right size, Right pack Promotion – correct forecast, responsiveness, promo packs Price – competitive (Threat from DOBs) NPD – manage distribution and flexibility OSA – On Shelf Availability MAKE 252 factories Office Manufacturing Storage Sipoo Flen Waste management – Delivery and changeover Stocks – Balance between service and DOH OEE – (Overall Equipment Efficiency) CCFOT – (Customer Case Fill On Time) TPM - (Total Productive Maintenance) Odense Copenhagen CHALLENGES Responsiveness – the “new” way of reducing stock while keeping high service level RVS/GVS- (Regional/Global virtual sites) – Share best practise Centralizing - MRP, transport, buying End of line flexibility – decrease re-pack (product manipulation) Partner to Win – in buying Produce more with less environmental impact (landfill, water, C02) From cost pressure -> End 2 End supply chain