Why Design???

advertisement

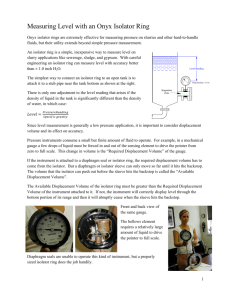

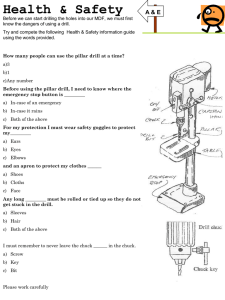

MET 210W: Instructor: • • • • B. Michael, P.E. 230 REDC Building 898-6192 rxm61@psu.edu Consultant: • • • • Elastomer design Structural Analysis FEA Vibration Analysis MET 210W Machine Design Lecture – 6:00 – 7:15 pm - Mon/Wed (106 REDC) Lab Section 1 – 7:30 – 9:20 pm - Mon (106 REDC) Lab Section 2 – 12:20 – 2:10 pm - Fri (101 REDC) MET 210W: What is this course??? • • Mott Text: Machine Elements in Mechanical Design – 4th Edition. – Part I focuses on reviewing and upgrading readers' understanding of design philosophies, the principles of strength of materials, the design properties of materials, combined stresses, design for different types of loading, FAILURE THEORIES, and the analysis and design of columns. BASICALLY A REVIEW OF 213!! – Part II is organized around the design of a complete power transmission system, emphasizing the interrelationships among machine elements in addition to their unique characteristics. Included are belt drives, chain drives, gears, shafts, keys, couplings, seals, rolling contact bearings, and completion of the design of a power transmission. BASICALLY A GEAR DRIVE – Part III presents methods of analysis and design of plain surface bearings, linear motion elements, fasteners, springs, machine frames, bolted connections, welded joints, electric motors, controls, clutches, and brakes. BASICALLY MISC. Machine Elements!! A CD-ROM for the mechanical design software MDESIGN is included with each book. This powerful software enables users to quickly complete the design of many of the machine elements discussed in the book. MET 210W • • • • Review Syllabus Review Course Schedule Review Homework Guidelines! Chapter 1 – The Nature of Mechanical Design Course Title Page Name & Date Chapter & problem no. Sketch of situation What you are to find Always include UNITS FBD’s as necessary No more than TWO problems per page LATE HOMEWORK NOT ACCEPTED Engineering Calculation Paper Box or underline answers Homework Use this as a model!! Chapter 1 – The Nature of Mechanical Design • • • • • • Markets Design process/flowchart Skills needed in mechanical design Functions, design requirements, etc. Misc: preferred sizes, units Brief Intro: http://www.youtube.com/watch?v=7zB6E2Fm7zg&feature=related Why Design??? •Only true wealth a country can create is through manufactured goods and technology!! •Innovation and technology brought to life thru Design (improve quality of life). • Design/Innovation makes us dominant nation. Manufacuring? – Manufacturing 1970 vs Current: – – – Machine Tools Color Televisions Semiconductors 1970 100% US 1970 100% US 1997 25% US 1997 5% US 2000 30% US • US still leads in innovation (rest of world catching up): IBM – consistent record holder with 3,148 (‘07 # patents awarded. Other companies catching up!!): source: http://www.baselinemag.com/c/a/ProjectsEnterprise-Planning/IBM-Samsung-Churn-Out-Most-Patents-in-2007/ Mechanical Design Markets: Consumer Products – lawnmowers, household appliances, et. 1. – Cost and safety major issues (o’head blade deck) 2. Manufacturing systems/ general industrial equipment – machine tools, conveyers, test machines, inspection machines, et. 3. Construction Equipment/ Agriculture Equipment – loaders, scrapers, vibratory rollers, pavers, tractor, harvester, et. 4. Aerospace Industry – commercial airliners, helicopters, military jets, et. – Performance, safety, weight major issues (o’head helicopter rotor) 5. Transportation – truck, bus and automotive • Focus of this class on machine design/ machine elements (2/3 above) A Typical Mechanical Design: Skills needed in mechanical design?? Sect 1-3) Phases of Design Phases of Design: (similar to Mott, F 1-11) Recognize the Need Definition of Problem (function, requirements, and evaluation criteria) Synthesis Analysis & Optimization Evaluation ITERATION From: Presentation Shigley, Mechanical Engineering Design, 2nd Ed, McGraw-Hall, 1972 The Design Process: 1. Recognize need: – Can be system or component – OEM vs. supplier (big difference) 2. Define Problem and Requirements: – Requirements fall under 3 categories (see text): • • • Functions Design Requirements Evaluation Criteria 2. Problem Definition Functions • Tell what the device is supposed to do. • Can be one or more somewhat general nonquantitative statements • Use action phrases: – – – – To support… To lift… To regulate… To bend… - To constrain… - To orient… - To change… - To limit… 2. Problem Definition Design Requirements • Detailed & Specific requirements of the project giving quantitative data where possible. – Expected performance levels – Environmental conditions in which the thing operates – Limitations on space and weigh – Available materials or components that may be used. Generic design requirements: strength, reliability, wear, corrosion, thermal properties, surface appearance, finish, color, life, size, shape, NVH, maintenance, manufacturability, recyclability, safety, weight, shape, size, flexibility (stiffness), lubrication, liability, friction, etc… The Design Process: 2. Define Problem and Requirements: • Evaluation Criteria (RANKING) – statements of desirable qualitative characteristics of a design that assist the designer in ranking various designs and determining which one is optimum. Examples: cost, safest, easiest to manufacture, stiffness to weight ratio, strength to weight ratio, etc. Sometimes called design index (MET 470) Show drawing! Example: Function, Design Requirements, Evaluation Criteria (Helicopter Rotor) • Functions: – Receive power from transmission – Rotate to create lift – Flexible blades for manuevering • Design Requirements: – Flight critical parts must have infinite life. – Max weight and package size not to exceed …… – Operating temperature ……… (-40 to +200 F) – Maximum rotor blade angle = …… degrees (60) – Blades must be able to rotate +/- ……. Pitch (+/- 20 deg) – Rotor speed = …….. (4.5 Hz) – Must be able to climb 4000 ft I, 95 F in 30 sec – Etc………………. Show drawing! Example: Function, Design Requirements, Evaluation Criteria (Helicopter Rotor) • Evaluation Criteria: – Best design: highest strength to weight ratio – Best design: most durable – Best design: highest stiffness to weight ratio 3. Synthesis: The Design Process – cont’d: – The stage where you come up with options and ideas or basically BRAINSTORMING!! Always ask: can a vendor supplied component be used?? Ex: Lord product selection guide: http://www.lord.com/Home/ProductsServices/VibrationShockMotionControlProducts/Industrial Catalog/tabid/3300/Default.aspx Alternatives • Brainstorm and come up with as many different solution schemes as is possible. • Never settle on your first idea. • The most off-the-wall initial idea can lead to a unique and innovative solution. • Design is an iterative solution to a problem. The Design Process – cont’d: 4. Analyze and Optimize – Finalize design, create drawings, analyze stress, weight, FEA, etc.. – If designing series or families of parts – look at automating (spreadsheets, ANSYS macro, etc.) The Design Process – cont’d: 5. Evaluation: – Build prototypes and TEST!! Is design acceptable? Areas of improvement/refinement – may go back to 3! 6. Presentation: • • • Generally an oral presentation to the customer and/or upper management The opportunity to sell the design Good designs lead to better pay and esteem for the designer. My experience? Most iterations occur between 3 – 4 – 5!! Example seismic isolator: brainstorm, analyze, build prototype and test, start over!!!! Show design summary How does this design process work?? • NVH Caster: http://www.jarviscaster.com/pdfs/News%20Release%20Stealth.pdf 3 2 1 4 Functions: Support payload while providing compliance for shock inputs. Design Requirements: 1. Must support load of 1,000 lb 2. Must have vertical mounting height of 6.24” 3. Wheel diameter must be 4” 4. Static vertical deflection of wheel = 0.5” 5. Max vertical deflection of wheel = 1.0” 6. Hole pattern for mounting = ……… 7. Fatigue life = 20,000 cycles at 0.5” +/- .2” 4 Next Generation Caster Communicate the Details As the field requested it As marketing ordered it As engineering designed it As installed As the plant manufactured it What the customer wanted CASE STUDY – Drill Bit Isolator • Drill bit isolators for underground mining – all metal components and elastomer must be safe! • Design requirement: 8,000 lb thrust load and 300 lb-ft (3,600 lb-in) torque – these are basically the cutting forces. • Must have adequate life (2 – 4 weeks). • Must provide noise attenuation (4 – 7 dBA). – Stiffness and damping requirements Bit Isolator Drill Depth up to 48” Chuck Isolator 1 3/8" DBI, R. Michael, PE Results showed that in combination, the bit isolator and the drill chuck isolator provided a 7 dB(A) reduction in sound pressure level at the operator position. Ref: Noise controls for roof bolting machines, P. Kovalchik, A. Smith, R. Matetic and J. Peterson 1 3/8" DBI, R. Michael, PE FULLY BONDED: 1 3/8”” Chuck isolator: 1 3/8” Drill Bit Isolator – Design Review: Drill Bit isolator: 4/10/2015 30 1 3/8" DBI, R. Michael, PE Critical Area!! Look at metal components: Where would you expect max stress to occur? 4/10/2015 31 1 3/8" DBI, R. Michael, PE Integration of Machine Elements (ref 1-5) • Aka: Design coupling. Design of one machine element impacts the others. • Happens a lot in mechanical design (examples:…..)! • Speed reducer (F 1-12) what design first? Most critical component!! What would you design last?? Preferred Sizes and Shapes -see appendix 2 -use standard sizes -use standard shapes (ASTM A36 structural steel) Review section 1-9 You will need to solve problems in both unit systems but bulk of MD problems will be in English units. Bob Michael – Sputz Design Philosophy: • Get as much input as you can from your customer – do not start the design process until you get from them (IN WRITING) design requirements and functions (i.e. Make sure you’re both on the same page). Send them a “generic” design requirement form (See example). And while you’re at it: – – • Brainstorm as many ideas as you can. Create several designs (CAD, hand sketch, etc.) – – – – – • • • • IMMEDIATELY ADDRESS: Prototype costs (including tooling), target production costs, intellectual property ownership, business agreement. Make sure your customer understands several iterations could be involved to “get it right” Send these designs to your customer and get their input. If feasible, incorporate one or more of their recommendations into the design (Joint Ownership!!!). Refine your design Brainstorm some more (while you’re cutting the grass, in church, wherever, think about your design until you’ve exhausted all possibilities). Talk to the “experts”: manufacturing, vendors, metallurgist, material scientist, etc… Don’t reinvent the wheel (check existing patents, old drawing archives, senior level engineers) Finalize design and send to customer for approval Prototype, Test (Field evaluations should be done as well) Refine, prototype test, etc. DONE! File patent and Start Selling!!!!