PROCESS SAFETY MANAGEMENT

advertisement

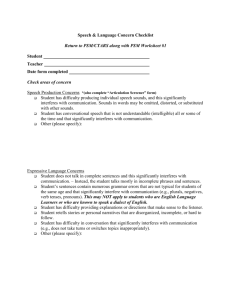

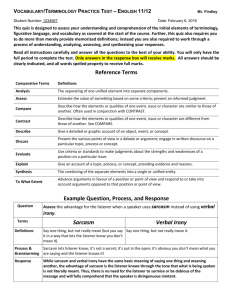

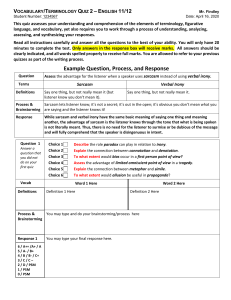

Process Safety Management …. and its Impact on the Professional Engineering Community PRESENTATION OVERVIEW Brian D. Kelly P Eng BriRisk Consulting Ltd. Calgary AB T3G 5J6 Sept 14, 2010 1 Process Safety Management is a comprehensive framework of activities for managing the integrity of a hazardous (chemical) operation. Its goal is to eliminate (prevent and mitigate) loss of containment incidents. Loss of containment events can lead to fire, explosion or toxic effects and may result in large numbers of casualties. 2 Occupational Health and Safety • • • • • • Workplace rules Worker training Supervision Individual behaviors Safety equipment Focus on individual well being Process Safety • Collective commitment • Addresses events over which the individual worker has little or no control • Focus on systems • Broader impact – events that could affect groups of workers or general public 3 Early Development Process Safety concepts were first adopted by companies that specialized in the production of highly hazardous chemicals (DUPONT, ICI). 1984 Bhopal, India chemical plant incident released toxic gas into local community causing the deaths of 3000 people. Analysis indicated the accident was preventable through formal management systems. Industrialized nations formally adopted Process Safety Management. 4 PSM Protocols Several PSM protocols exist worldwide. OSHA 1910.119 (US) is legislated and requires “designated” operations to comply with provisions of 14 element framework. Center for Chemical Process Safety (industry alliance) recently developed a 20 element risk based framework that better addresses people, process and equipment issues. PSM element framework should be tailored to type of operation. 5 Canadian Requirements No formal PSM regulation per se. CEPA 1999, section 200 (Environment Canada) mandates the development and implementation of emergency response plans for environmental emergencies in designated high hazard industries. Bill C-45 (Westray bill) includes amendments to the criminal code of Canada. – Legal duty for all persons directing work to take “reasonable steps” to ensure the safety of workers and the public. – Severe penalties for failing to ensure safety and integrity of operating facilities. 6 Learn from Experience Manage Risk Understand Hazards and Risk Commitment to PSM PSM Structure 7 Risk Based PSM Framework Commit to Process Safety Process Safety Culture Compliance with Standards Process Safety Competency Workforce Involvement Stakeholder Outreach Learn from Experience Incident Investigation Measurement and Metrics Auditing Management Review and Continuous Improvement Understand Hazards and Risk Process Safety Information Hazard Identification and Risk Analysis Manage Risk Operating Procedures Safe Work Practices Asset Integrity and Reliability Contractor Management Training and Performance Assurance Management of Change Operational Readiness Conduct of Operations Emergency Management 8 PSM Structure Each of the 20 elements of Risk Based Process Safety is fully described in the CCPS Guidelines book: Guidelines for Risk Based Process Safety, Wiley, 2007, ISBN 978-0-470-16569-0. A better understanding of process safety may be acquired through a participative workshop with other professionals. 9 Engineering Discipline Involvement CHEMICAL CIVIL MECH ELECTRICAL Process selection Operating conditions Safe operating envelope Process design Process control Safeguards Monitoring Site layout Elevated structures Grading Drainage Buildings Facility siting Infrastructure Pressure envelope design Rotating equipment Codes Monitoring Reliable power Arc flash protection Area classification Grounding bonding GFIs 10 Why Process Safety Management? PSM framework is essential to avoidance of loss of containment incidents – these can put a company out of business PSM drives rigor and discipline into an operating organization An effective PSM framework will also address smaller incidents including those not associated with loss of containment PSM will improve the bottom line 11 Executive Support Executive support is required in the following areas to ensure PSM success: 1. Financial – additional resources (people and money) required for PSI, PHAs, training, maintenance etc. 2. Production penalty – may need to suspend production if warranted by serious process safety concerns 3. Hold organization accountable – engage in discussions with operations personnel about process safety issues. Ask questions 12