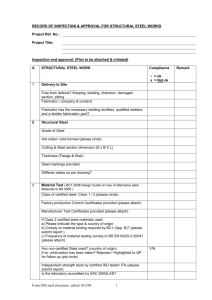

Execution Class

advertisement

1. 2. 3. 4. 5. 6. Background to CE Marking Implications for Fabricators What products does it cover? How do I implement it? What about specifiers? What about galvanizing? 1. Background to CE Marking Objective: To promote common standards across Europe in order to make trade easier. Phased introduction started 1988 21 directives requiring CE marking 3 directives not requiring it. Requirements vary between directives To ensure items being sold are: well designed, and safe. Toys and electronics are well known To be CE marked Construction Products Directive •Removing technical barriers to trade •Replacing national standards with harmonised EU standards. Being replaced with the Construction Products Regulations 7 Main requirements… • • • • • • • Mechanical resistance and stability Safety in case of fire Hygiene, health and environment Safety in use Protection against noise Energy economy and heat retention Sustainable use of natural resources 2. Implications for Fabricator •Who is affected? •What does it mean? •What do I do? •What deadline? •Consequences of not doing it? BS EN 1090 :Execution of steel and aluminium structures Part 1 :Requirements for conformity in assessment of structural components Part 2 :Technical requirements for steel structures When? CE marking is mandatory from July 2014. Non-compliance is a criminal offence Consequences? Non-compliance is a criminal offence “Policed” by Trading Standards. 3. What products does it cover? Covers all fabricated steelwork from purlins to portals, from bridges to frames. All steel into the “built environment”. Covers components made from: Hot rolled steel, Cold-formed steel, Flat products (plates, sheet and strip), Bars, castings and forgings. Applies to: •Series production (purlins, sheets, decking etc) •Bespoke structures •Components made from kits of parts What products does CE Marking apply to? Construction Products – “any product or kit which is produced and placed on the market for incorporation in a permanent manner in construction works or parts thereof and the performance of which has an effect on the performance of the construction works with respect to the basic requirements for construction works.” Article 2 definition 1 of regulation No EU-305/2011 Construction Works – “any buildings and civil engineering works.” Article 2 definition 3 of regulation No EU-305/2011 What does that practically mean? •Steel frame (columns, rafters, bracers etc) •Lintols, beams, frames, ties •Stairs, handrails, fire escapes, doors •Culverts, bridges, walkways •Water works access systems •Roads and highways systems 4 How do I implement it? Constructor responsibility Manufacturer’s declaration of conformity Warranty that product meets the specification Safety critical products Must have suitable Factory Production Control (FPC) FPC needs to be certified by a Notified Body Linked to Execution Classes Welding is a special process Reliance on the “system” and the “personnel” Competent welders and inspectors required Competent welding coordinator How do I implement this? 1. 2. 3. 4. Know the requirements of the standards applicable to your products. Use the specified test methods to ensure conformity with those requirements. Implement a system for controlling regular production. Mark the products in the specified way using a suitable classification and designation system. Factory Production Control. ISO 9001 is a form of control, and probably Covers most of what is required. Do you have traceability of materials? Of processes? Of qualifications of welders? Notified Body Similar to the body who audits your ISO9001 quality system. Independent, authorised by EU, audits your systems. Execution Class One level of control is not suitable for every application. The degree of control in welding components for nuclear Industry is not the same as for a fence! Execution classes divide these levels of consequences of failure into several categories. There are four execution classes Determined in a similar way to risk assessment. 1. 2. 3. 4. Simple structure, low consequence Medium structure, moderate consequence More complex, higher risk Most complex, highest risk. Examples 1. 2. 3. 4. Small fire escape, gates, handrail Farm Building structure Office Building, factory Nuclear Power, Oil & Gas. Execution Class determined by these factors: •Consequence Class •Service category •Production Category Setting the execution class is the designer’s responsibility Welding Coordinator Welding is a critical process. Coordination of materials, processes, people Qualifications? Standards? Documented Processes? Implementation example… Structural steel fabricator Planning to fabricate for a factory building Has the contract in hand, and is planning the execution. Steel grade: Standard: Designed S235 EN10025-2,3,4,5; EN10149 - 2, 3; Engineer 5. What about Specifiers? The specifier or designer of steel products covered by the regulations must state the standard to be worked to and the execution class. Some designers are unaware of their responsibility in this respect. Consequence Class: Service Category: Production Category: = Execution Class CC2 SC1 PC1 EXC2 Joe Bloggs Fabrications Ltd 1 Doric Place, Abedeen Structural Steel components for portal frame building in Ellon, ref XY4567. Execution Class 2 BS EN 1090-1 2009 2272 Structural Steel components and kits for use in building and civil engineering works 6. What about galvanizing? What happened? Galvanizing can have an impact on structural integrity. Part of a process not under the control of the fabricator Fabricator needs some assurance that integrity has not been compromised. Prior communication is key! Discuss the plan of action with the galvanizer. Swap drawings where appropriate Changing a drawing is a low cost activity compared to changing steelwork between fabrication and galvanizing. Galvanizers Association with British Constructional Steelwork Association have developed a course for post galvanizing inspection. Qualified inspectors Good information Test certs, material descriptions, drawings Typical Info to consider for galvanized steel. •Steel composition •Identification of significant surfaces •Flame, laser or plasma cut surfaces •Vent and drainage holes adequate •Coating thickness requirements •Passivation or painting requirements after galv. What should you expect from the galvanizer? •Qualified inspector available. •Inspection of the material pre and post galvanizing. •Zinc melt must conform to ISO1461, and be proven to conform. •A Quality Management System conforming to ISO9001:2008 •A system of material traceability. •A record keeping system that preserves info for TEN years. Cold Comfort…. Other industries have the same problem. Insulation products: August 2012 Aggregates (rock!) Toys (covered in 1988) Mastic and adhesives Glass Sewer pipes Toilets What now? Who can help? BCSA TRAC RIDBA Barclay Phelps IES http://www.steelconstruction.org/ http://www.tracglobal.com/content/ce-testing-and-marking?gclid=CMbgwtfIx7cCFavHtAodFmcA9Al http://www.ridba.org.uk/cemarking.htm http://www.barclay-phelps.com/exemptions.html http://www.ies.co.uk/ce-marking.php?gclid=CNaMx9XIx7cCFUXMtAodkGMAag Many more…. You can download this presentation from our website to get clickable web references. References http://www.legislation.gov.uk/uksi/1991/1620/contents/m ade http://ec.europa.eu/enterprise/sectors/construction/files/ guidance-papers/gp-d_en.pdf http://ec.europa.eu/enterprise/policies/single-marketgoods/documents/index_en.htm http://www.steelconstruction.org/ If you would like a copy of this presentation, please leave contact details and we’ll get it to you. (1.6 Mb)