Fiber Optics

advertisement

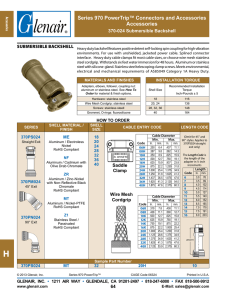

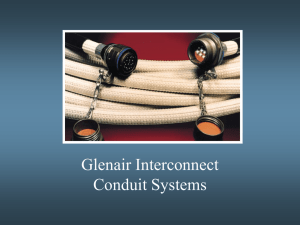

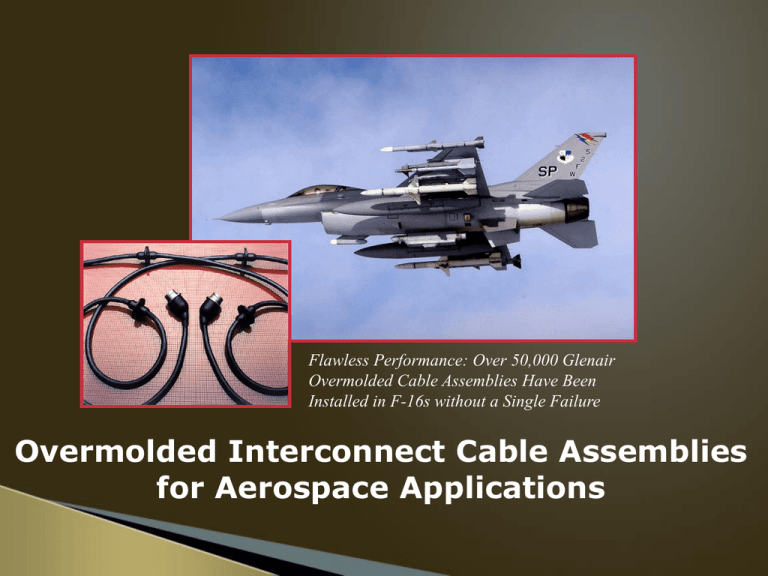

Flawless Performance: Over 50,000 Glenair Overmolded Cable Assemblies Have Been Installed in F-16s without a Single Failure Overmolded Interconnect Cable Assemblies for Aerospace Applications Environmental/Mechanical Stress Factors in Aerospace Interconnect Cables High Performance Cable Assemblies Must Be Able to Withstand Damage From: Shock Vibration Fluid Immersion Abrasion Clamping Combustion Corrosion Temperature Cycling in Jet Fuel Altitude Fungus Pressure Extremes Pull Forces Outgassing Aging The Advantages of Overmolding Outstanding environmental protection for harsh and caustic environments compared to braided or booted solutions Viton, EPDM, Butyl and Glenair proprietary materials provide robust protection for connectors and cables in harsh/caustic environments Mechanical performance is also enhanced Injection molding/transfer molding is a simple, reasonably priced solution to physical protection Design flexibility: from simple point to point, to complex multiple branch assemblies—even fiber-optic and hybrid electrical/optical designs Typical Cable Construction Connector Overmold Cross-Section Overmolding as a Solution to Managing SinglePoint Ignition Sources in Aircraft Fuel Cells Turnkey Solution to FAA SFAR-88 Requirements Overmolding effectively eliminates all cable and wire ignition sources, including arcing and ESD Also improves longevity of service Reduced installation and maintenance cost Controls corrosion/conductivity problems Improves reliability and safety Overmolding as Solution to Cable Routing and/or Weight Reduction Efficiently Designed Multi-Branch Harnesses Reduce Overall Weight and Package Space of Interconnect Cables Turnkey solutions with Glenair Connectors, Backshells, and Assembly may be optimized for reduced weight Routing performance enhanced with range of standard Glenair tooling for all angles and junctions History of Glenair Overmolded Cables for Fuel-Cell Applications F-16 Fighting Falcon Modular conduit designs failed repeatedly in F-16 and other front-line fighters. Glenair introduced unique design to solve leakage, reliability and installation requirements Design incorporated new overmolding materials and integral bulkhead fittings Additional Military Reference Applications Proven Performance for Bell, Lockheed, Boeing and ETC F-18 Fuel-Cell Assembly Advanced F-18 E/F Fuel Cell Assembly with integral fiber optic media F-22 Overmolded Fuel Cell Assembly and Wheel Well Assemblies V-22 Fuel Cell Assembly Bombardier Bulkhead Fuel-Tank Connector Assembly C-17 Overmolded Conduit Fuel Cell Assembly Spotlight On Glenair’s C-17 Overmolded Conduit Solution New Glenair Design Met all Requirements and Significantly Reduced Installation and Maintenance Costs Sealed conduit system with integral clamp mountings Replaced rigid metal tubing system with significant installation cost savings Achieved all safety, reliability, and weight objectives C-17 Overmolded Conduit Solution: Detailed View New Glenair Design Met all Requirements and Significantly Reduced Installation and Maintenance Costs Cable Routing and Packaging Capabilities An almost unlimited range of breakouts and layouts Straight, 90 and 45 degree angular specifications. Existing tooling for all common molding adapters and connectors. Breakout, bulkhead and transition tooling for all common configurations Standard molding materials as well as new proprietary formulas and new mass-produced injection processes. Molded Cable and Connector Identifiers Production Packaging Overmolding as a standard catalog offering Point-to-Point cordsets available for all Series 80, Series 22 and D38999 fiber optic connectors Standardized part number development Accelerated lead times Additional Cable Shop Capabilities: Custom Multi-Conductor Cables For exacting operational and environmental conditions Custom electrical, fiber optic and hybrid configurations Bulk cable supplied in short one-time runs as well as unlimited quantities and lengths One of the industry’s broadest selection of braided shielding, coverings and extruded jacketing, including NBC (nuclear, biological, chemical) materials Cable design and engineering support covering every EMI/EMP, mechanical and environmental design consideration Additional Cable Shop Capabilities: Metal and Fabric Overbraiding Durable lightweight cable assemblies Flexible, and elastic overbraiding provides physical protection and EMI Shielding Extreme temperature protection: from -100oF to +500oF Smoothes irregular shapes and reduces snagging in lacing- tape bound harnesses Adds flexibility and repairability to harness designs Available in bulk or integrated into the harness assembly service Ultra-Lightweight Composite RFI/EMI Braided Shielding Nickel Plated Composite Shielding Offers Unique Solution to Electromagnetic Compatibility Expandable, flexible, highstrength, conductive, elastic composite material Provides abrasion resistance and EMI shielding at a fraction of the weight of metal braid Application Development The Bid Process Assessment of overmolding work is essentially a bid process and costing exercise as most jobs are submitted with complete BOMS and assembly schematics. New applications are nevertheless evaluated for mechanical, EMI and environmental requirements. Glenair will often add value with superior knowledge of wire and cable layout and assembly, especially in prototypes. Not Just Another Pretty Cable The Ultimate Harsh Application Environment Halliburton’s Oil Well Recovery and Restoration Division employs specialized trucks equipped with seismic recorders to generate accurate oil well status data. The field generators which power the system use interconnect cabling which must withstand severe weather, abusive handling and caustic chemicals. Glenair overmolded cable assemblies provide flawless, durable service in this extreme environmental application