Rakesh Verma Samsung

advertisement

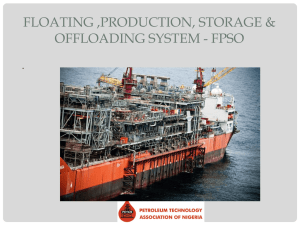

India Drilling & Exploration Conference (IDEC) 2013 Does Project incubation define Project success? 23rd May 2013 By: Rakesh Verma CTO and Vice President Samsung Heavy Industries India Pvt. Ltd. Introduction • FPSOs a popular choice in recent years. • Majority of FPSO projects incur significant project delays and budget overruns. • Conceptual / Tendering phase a bone of contention Objective • To show the challenges of current Conceptual / Tendering phase practices and how this can affect the success of a FPSO project. • To highlight the strategic roadmap to better results Outline • Challenges • Key drivers • Current practices • Impacts and challenges • Way forward Decade 10-20 Challenges History shows that FPSO projects have a turbulent past. Data Source: IPA Decade 10-20 Challenges • Cost and schedule overruns regularly surfacing. • Successfully executing a FPSO topsides project on time and budget is a serious challenge. • Most FPSO projects, and in particular Lease FPSO’s, are fast track projects. • Consequently few FPSO lease companies make healthy profits. • Many leased FPSO’s struggle to meet expected delivery schedule, production regularity and production rate. KEY DRIVERS TO THE CHALLENGES Market Trends • Increasing size & complexity (Brazil main driver) • Field specific solutions • HT & HP wells • Heavy Oil • Salt and CO2 issues • Deep waters • Harsh environment • Local content at design and construction phase Why the hurry? • The Operator Company have invested a lot of money in Seismic activities and expensive drilling programs. • First oil as quickly as possible in order to start return of investment. CURRENT PRACTICES Current tendering practices • Field Operator spending long time on preparing, however first oil date does not change. • Functional specifications. • Short bidding period. • Pushing risk over to the contractors. • FPSOs high profile developments, with senior management “attention”. Schedule commitments made independent of project realities. • Consequently definition stages are arbitrarily shortened. Insufficient time to complete definition deliverables. IMPACTS AND CHALLENGES Skimped Engineering Definition and its peril Data Source: IPA Impact of tendering practices • FPSO projects are more likely to have upsets… • Hence need a more matured conceptual design and a balanced tendering process Data Source: IPA Increasing the odds Contractor 1 Operator Contractor 2 Contractor 3 • Each contractor different philosophy • 3 different layout • Redundancy philosophy • Options Topsides Provider A very basic Tender / FEED Layout Higher level of detailing needed during tender phase. FEED Stage Layout Detailed Engineering Data Layout HP Compression Module Layout comparison for one of Samsung’s past projects. Chain reaction Slippage of Engineering Deliverables adds to Project costs. Late engineering and its link to cost growth Data Source: IPA Chain reaction • Cost growth in Engineering leads to growth in Fabrication. • 50 % growth in Engineering leads to 20% Hull/Topsides fabrication growth. Data Source: IPA WAY FORWARD….. Working together • Lease contractors pick a strategic partners for various key supplies. • Specialists companies can often come up with better, more robust and cost efficient solutions that give added value for client. • Early involvement in order to allow sub-contractors sufficient time to make quality bid and reduce risk for both parties • Balanced contracts (Back to back) Project definition phase utilization • Front loading effort in the project definition and tendering phase will provide a mature and predictable basis for weight and cost estimate. • The design status at authorization may have a significant effect on project cost, schedule: Basis for equipment design and bulk material quantity Key element of an accurate cost estimate • Late changes to process design after start of detailed design are costly and a threat to delivery schedule. The bid workflow (typical) Example: Typical time given 4-6 weeks Example: Typical time needed for above process 8-10 weeks Topside Module EPC Project execution strategy Tender phase as far as possible towards detail engineering phase. Conceptual Engineering Detail Engineering Contract award Fabrication Potential risks • Poor quality information from suppliers/sub contractors. • Large number of clarifications and deviations Example: “A process guarantee is given provided the proper use of chemical injection program” • Delivery schedule uncertainties. • Variation Orders with significant cost growth. Way Forward • Front loaded in project definition phase (Owner) • Matured Conceptual design (Owner) • Participation by key stakeholders during Concept finalization (Owner) • Early involvement of potential Contractors….Design competition (Owner) • Inject incentives and risk sharing measures (Owner) • Focus on Life Cycle cost (Owner / Bidder) • Pick a few strategic partners & develop long term relation (Bidder) Thank you !