Team 2 prototype research and development project

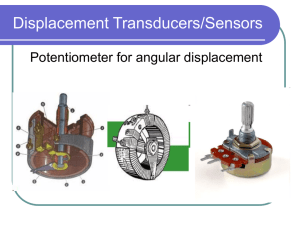

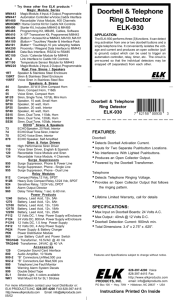

advertisement

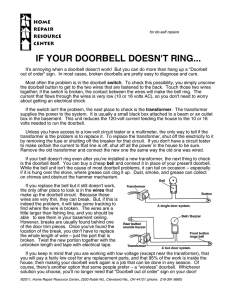

Digital Doorbell Team 2 Tyler Blaker, Mike Woessner, Jose Pina, Bill Kessler, Jesse Yanik, Justin Bayham, Brandon Roberts, Mike Goggins, Ralph Voltz Project Goals Doorbell Prototype – – – – – Two moving parts Multiple processes Multiple materials Under 25 dollars apiece Mass produce 10 products Learn and apply technologists’ management Skills Meet consumer demands Kit and Prototype We used an Electronics Learning Lab to design the circuit We transferred the circuit to our PC Board to make our prototype Final Product From our prototype and improvements, we made our final product This product has a speaker to omit sound, LED to omit light, and potentiometer to alter pitch How It Works The current travels through the resistors to the speaker and the LED The frequency can be adjusted by turning the potentiometer The potentiometer alters the amount of current that runs through the circuit Problems and Improvements Problems • The kit had 5 holes and the prototype had 3 holes • We used jumps that made things confusing • We shorted some components by soldering them together Improvements • We had to use extra wires to “create” more holes • Used long jumps to show where things were going • We spread out the entire circuit to eliminate unwanted solder connections Cases Cases Cases Tool #1 Dealt with basic teamwork fundamentals – Communication skills, emphasis on quality, preparations as a team. Allowed first opportunity for our team’s proposal idea in actual writing. Tool 2 Materials – The toolkit explains the refinement and classification of materials, their structures and characteristics for each of the materials talked about in the presentation. Processes – Some of the processes talked about where Forming, Cutting, Fastening, and Conditioning. Tool #3 “Process Engineering, Design And Innovation” Has to do with Product Development, the Design Process, Research, and Improving the overall product. The SDA’s completed in Tool #3 were the MMA, CA (Cost Analysis), DSD, and BSOP. “Process Engineering, Design And Innovation” Process Engineering – Identify, analyze, and solve any problems which would improve quality and productivity. The Design Process – The entire process from basic ideas to production. Innovation – Changing an existing design or product to make it better and more competitive. MMA and CA (Cost Analysis) Man Machine Analysis – Looked at issues and problems that occurred using the machines like cutting the acrylic or soldering the circuit. Cost Analysis – Concentrates on Direct Costs with a breakdown of all individual part costs and Labor. DSD and BSOP Documentation System Design – The Discussion board on Blackboard is very organized and can be easily accessed by any group member on the computer. Basic SOP – Helped with writing SOP’s for all tools used in production. • • • • Soldering Iron Band Saw Hand Drill Drill Press Tool 4 - Cost analysis and Productivity The forms in Tool 4, Break Even, Cost Analysis, Standard Operation General Analysis and the Time and Method Analysis all deal with cost analysis and productivity Manufacturing Industries constantly deal with costs and productivity of their workers Cost Analysis The BEA and the CA both have to deal with calculating costs and determining what can be improved. With our product we calculated our CA with the materials we purchased, and calculated our own analysis Productivity SOGA and TAMA are both productivity forms for calculating the number of parts produced In our case we used our lab time to calculate how our time was spent and we kept track of what process we used to log on the SOGA Productivity Companies should take into consideration man labor vs. machines. After so long a service a machine should be replaced with a new machine that could increase productivity Tool 5 “Quality Systems” Designed to introduce technologists to quality improvement systems and to help them better understand how to put these tools in motion Quality is taking systems which help conformance and taking them to meet the market demands Quality Quality has the perspectives of total quality movement, quality functions deployment, quality costs, quality value analysis and global quality issues. ISO 9000 World wide effort to improve quality Used in all technical and business fields Purpose is to keep the technical standards around the world consistent so all parties can do business with each other Assembly line idea We split apart the team into two groups. – One group did the circuits • Place components on to board – Checked by quality technician • Passes or fails • Soldered components on to board – Checked by quality technician • Passes or fails Assembly line idea cont’ Continued: – The other group did the casing • Cut pieces out of the acrylic – Checked by quality technician • Passes or fails • Glued the pieces together – Checked by quality technician • Passes or fails Tool 6 Automation – Devices to accomplish specific tasks in a technological work place. Computer Integration – Computers have paved the way for many new opportunities in the manufacturing world. Automation Less manual labor Repeatability and precision production methods Usually skill levels are required Increases in energy and non-human resources Increase in productivity Reduced cost in price Computer Integration Always plan ahead for growth within the company This is a very serious thing, always plan for hidden factors Always set realistic goals that can be obtainable Always being thinking of new ways to improve, but start off realistically Never go through the middle man Computer Integration There has been a lot of computer integration over the years, we even used it in our doorbell. - The PC board is an easier way to solder components. - Another useful product of computer integration is our 555 IC Timer chip. - Computer Integration gave us a lot of our components for doorbell. Conclusion We have achieved our goals of: – Building a working prototype. – Replicating mass production on a smaller scale. – Working together as a team to obtain a common goal. – Become more educated in the processes and fundamentals that will allow us to become more successful in a technologist’s world.