T Pedersen

advertisement

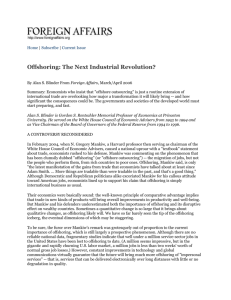

Offshoring and Globalization of the Value Chain Torben Pedersen Professor Center for Strategic Management and Globalization Copenhagen Business School Agenda • Definitons • Theories – Porter’s value chain – Modularization • Case: Ecco – different offshoring strategies • Highlights from an international survey • Danish data on offshoring of advanced activities • Case: Coloplast – Managerial and organizational challenges in offshoring Sourcing (onshore-nearshore-offshore) . Location Home country (onshore) Foreign country (offshore) Operator Nearshore Contractual Partner (Onshore) outsourcing Offshore outsourcing (outsourcing) Ourselves (insourcing) Captive offshoring (FDI) Offshoring – Global trends What is driving the offshoring? • New information and communication technology makes it easier to codify and standardize activities • New technology makes it possible to disconnect and disaggregate activities – e.g. e-business, e-learning, library services • New important markets like China and India is opening up and claiming their role in the world economy Porter: A value chain approach A change from dispersed to concentrated configuration strategies in which global sourcing plays a vital role Firm Infrastructure Human Resource Management Technology Development Procurement Inbound logistics Operations Outbound Logistics Marketing and sales Service A dispersed value chain configuration with low interaffiliate coordination UK USA Japan Marketing & Sales A concentrated value chain configuration with high inter-affiliate coordination. UK Mgt Ireland USA Logistics R&D Manufacturing IT India M&S Marketing & Sales China What is driving the offshoring? • New information and communication technology makes it easier to codify and standardize activities • New technology makes it possible to disconnect and disaggregate activities – e.g. e-business, e-learning, library services • New important markets like China and India is opening up and claiming their role in the world economy Porter’s global value chain framework Coordination of value chain activities High Oprening of new markets Lower coordination (I&CT) and transportation costs Low New codification and standardization technology Dispersed Concentrated Configuration of value chain activities Take aways - Offshoring - Enabled by modularization/standardization - Benefits: Location-specific advantages - Comes at a cost: Increased coordination problem The starting point Value Chain Input Process Output Fine-slicing of the value chain Value Chain Input Process Output Location and organization Choice of location and organization ? Value Chain Input Process Output Danish textile-companies outsourcing/offshoring Concepts OPT CMT SOD Outward Processing Traffic (1985-1990) Cut, Make and Trim (1990-1995) Sourcing from own Design (1995-2000) Design Logistics Denmark Denmark Denmark Denmark Outsourcing Denmark Outsourcing Denmark Procurement Denmark Outsourcing Denmark Eastern Europe Processing Outsourcing Denmark Southern Europe Eastern Europe Cutting Outsourcing Denmark Eastern Europe Asia Sewing Packaging Quality control Branding Southern Europe Eastern Europe Asia Southern Europe Eastern Europe Asia Denmark Southern Europe Asia Denmark Denmark Denmark Fine-slicing of the activity: Smiley of the value chain.. Value added Branding and marketing Design Logistics Quality Control Packaging Procurement Sewing Processing Cutting Value chain Input Processing Output Smiley of the value chain.. Value added Denmark Design Branding and marketing Logistics Quality Control Packaging Procurement Sewing Processing Cutting Value chain Input Processing Output What is new about offshoring? • Disaggregation of the value chain and re-location of some of these more disaggregated activities • Sourcing motives are becoming more prominent than market seeking motives • In particularly, China and India (1/3 of world population) are becoming active on the global scene • Empirically: – The amount of offshoring has increased dramatically – The character of offshoring has changed to include service and knowledge activities ECCO A/S – Optimizing Global Value Chain Economics The history of ECCO • 1963 foundation of ECCO in Denmark • ECCO over time aims to produce most comfortable and modern footwear for work and leisure, focus on quality and comfort • 2004 => 90% of production exported, mainly to US, Germany and Japan 1963 Denmark (Foundation of ECCO) 1984 Portugal 1991 Indonesia 1993 Thailand 1998 Slovakia 2005 CHINA Global Lifestyle Casual Footwear Brand Sales (in US$ million) Rank 1 Company Clarks 2 ECCO 3 Rockport 4 Geox 5 Birkenstock 6 Bass 7 Catterpillar 8 Doc Martens Others Total 2002 1,399 29,2% 502 10,5% 385 8,0% 208 4,3% 270 5,6% 275 5,7% 209 4,4% 295 6,2% 1,252 26,1% $4,795 2003 1,534 29,6% 590 11,4% 361 7,0% 329 6,3% 300 5,8% 285 5,5% 210 4,0% 195 3,8% 1,383 26,7% $5,187 % change 9,6% 17,5% 6,2% 58,2% 11,1% 3,6% 0,5% -34,0% 8,2% Composition of employees in ECCO by geography 10000 8000 6000 4000 2000 0 1980 1982 1984 1986 1988 1990 1992 1994 1996 1998 2000 2002 2004 Employees in Denmark Employees outside Denmark Production of shoes (in pairs) 2000-2004 4.500.000 4.000.000 3.500.000 3.000.000 2.500.000 2.000.000 1.500.000 1.000.000 500.000 0 2000 2001 2002 2003 2004 Shoes produced in Denmark Shoes produced in Portugal Shoes produced in Indonesia Shoes produced in Thailand Shoes produced in Slovakia Location of ECCO’s value chain activities Value added Design and development Branding and Marketing Denmark Distribution Production process USA and Denmark High-tech shoe production Most complicated shoes Production of uppers Portugal Slovakia and Thailand Thailand, China and Indonesia Value chain Input Processing Output Home country Internationa Outsourcing Own production (% of all shoes) facilities (i.e. l sales remaining % of shoes USA 40 % 90 % Puerto Rico Dominican Rep UK ? 99 % (UK) Ecco Denmark 90 % 20 % Portugal, Slovakia, Indonesia, China, Thailand Geox Italy 45 % ? Timberland Clarks Slovakia Romania No one strategy fits all! 2006 Offshoring Research Network Survey Demographics Duke University / Booz Allen Hamilton 2006 Offshoring Survey Demographics Percentage of Forbes companies in US sample Forbes 100 Small (Not Ranked by Forbes) 20% 30% 14% Forbes 250 12% 11% Forbes >1000 13% Forbes 500 Forbes 1000 Source: Duke University/Booz Allen Offshoring Research Network 2006 Survey 537 firms surveyed in US, UK, Germany, Netherlands and Spain. Excludes third party service providers – 55% currently offshoring – 18% considering offshoring – 27% not considering offshoring – 1498 offshore functional implementations Major industries represented: Financial Services, Manufacturing, Telecom, Technology, Consumer, Media, Energy, Aerospace & Defense, Automotive Functions Offshored: Includes IT, Customer Service, Business Processes, Engineering, Marketing, R&D, Product Development and Design IT remains the most highly offshored function. The next offshoring frontier, however, is globalizing product and process innovation Cumulative Percentage of Firms Initiating Offshoring by Function 50% Cumulative Percentage of Firms Initiating Offshoring 45% 40% 35% IT Product Development (R&D, Engineering, Product Design) 30% 25% 20% Admin. Business Processes (F&A, HR etc.) Call Center / Help Desk Procurement 15% 10% 5% 0% 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 Source: Duke University / Booz Allen Offshoring Research Network 2006 Survey Access to qualified personnel and improving speed to market are growing faster as offshoring drivers than cost reduction Growth Rate of Offshoring Drivers Over Time % of Responses Rating Driver as “Very Important” and “Important” 90 Cost Reduction 80 70 Access to Qualified Personnel 60 Competitive Pressure Business Process Redesign 50 Increased Speed to Market 40 30 20 Access to New Markets 10 0 2004 2005 Survey Year Source: Duke University / Booz Allen Offshoring Research Network 2006 Survey 2006 Managerial and organizational risks are growing while risks associated with external factors are declining. Perceived Risks of Offshoring 2004 - 2006 % of Firms Citing Risk as “Very Important” or “Important” 60% Operational Challenges 55% Lack of Acceptance by Internal Clients 50% Loss of Managerial Control 45% Lack of Acceptance by Customers 40% 35% 30% Cultural Differences 25% Political Backlash 20% Political Instability 15% 10% 2004 2005 Survey Year Source: Duke University / Booz Allen Offshoring Research Network 2006 Survey 2006 Offshoring of R&D leads to job growth onshore, while offshoring of back office functions is associates with job losses onshore Average # of Employees Offshore vs. Average # of Jobs Eliminated Onshore 40 150 140 128 120 30 97 100 79 80 20 60 35 40 28 20 13 0 * On average, offshoring led to job creation Source: Duke University / Booz Allen Offshoring Research Network 2006 Survey &D *R De si g n od uc t Pr Ma rke tin g /S a le s g En gi n ee rin en ter Ca ll C IT Fin an ce /A -40 0 cc ou nti ng -20 10 -10 Average # of jobs eliminated onshore per implementation Average # employees offshore per implementation 160 Danish data on offshoring of more advanced activities Activities offshored (Representative survey of Danish firms, all sectors, Fall 2004) Share of firms Activities 2004 Expected 2007 Production 90 % 92 % Logistics & purchasing 17 % 28 % R&D 11 % 23 % Adm. 9% 16 % Sales & marketing 6% 11 % The Wind-turbine company Vestas’ disaggregation of the value chain in R&D ”In Novo Nordisk 90 percent of our research and development is svead and only 10 percent are really creative” Lars Guldbæk Karlsen, Vice-president of R&D Novo Nordisk Disaggregating activities Less advanced tasks R&D: More advanced tasks Test, patenting New inventions, design Production: Volume production Individual prototype or niche production Marketing: Canvas and tele sales Advertisement, branding IT: Service operations Programming, architecture Administration: Bookkeeping & payroll Management Data • Survey: Total population of firms in Eastern Denmark with 10+ employees ( = 3.600 firms) • 1.504 firms responded (response rate 42%) – 1.158 firms (77%): no offshoring – 346 (23%) firms have offshored activities • identified type of offshored activities and rated tasks whether less or more advanced tasks (Likert-scale, 1-5) • 113 firms (8%) have offshored more advanced tasks Heckman-model on 1.504 Danish firms Whether to offshore Share of knowledge workers + Knowledge seeking Number of offshored tasks Capital investment - Developed countries Captive offshoring Firm size Multinational company Financial performance Seeking cost advantages Market-seeking motive +*** +*** - How advanced are the offshored activities +** +** +** + + + -** + Take-aways • The offshoring of more advanced tasks is conducted by experienced and knowledge-intensive firms seeking knowledge and talent abroad • Not more common with captive offshoring to deleloped countries. • Offshoring is best analyzed on a more disagrregated level and we need to know more about interdependencies and complementaries etc. between the different tasks Strategies for control Disaggregation af banking activities Brands Smiley.. Creative innovative White collar jobs Blue collar jobs Marketing Branding R&D Design Manufacturing Input High-cost countries Low-cost countries Markets VALUE CHAIN Education and payment of engineers New engineers educated per year Annual income in $ US USA 59,536 75,000 (New York) India 82,107 6,000 (Mumbai) China 219,563 12,100 (Shanghai) Russia 82,409 3,400 (Moscow) Japan 104,478 71,500 (Tokyo)