System Requirements

advertisement

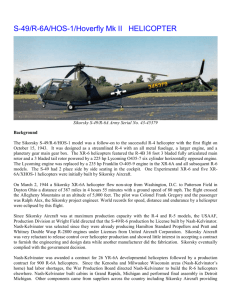

Wireless Test Instrumentation for Rotating Parts ECE 193 Advisor: Rajeev Bansal Olivia Bonner David Vold Brendon Rusch Michael Grogan ME 32 Advisor: Robert Gao Kyle Lindell Andrew Potrepka Sikorsky Contacts Company Advisor: Paul Inguanti pinguanti@sikorsky.com Senior Test Engineer: Chris Winslow cwinslow@sikorsky.com Test Instrumentation Engineer: Daniel Messner daniel.messner@sikorsky.com Outline Company Background The Problem System Requirements 2012-2013 Team Design Design Challenges Project Goals Timeline Budget Company Background Sikorsky Aircraft Company: - Founded in 1925 by Igor Sikorsky in Roosevelt, NY - Owned by United Technologies Company (UTC) - Moved to Stratford, CT in 1929 - Produces aircraft and helicopters - Well known models: UH-60 Blackhawk and SH-60 Seahawk Company Background Produced 30 military and 10 commercial helicopters in the first quarter of 2013 Generated $6.8 Billion [2012-2013] in net-sales Serves 25 governments world-wide Used in all 5 U.S. military branches Saved close to 2 million lives since first helicopter rescue mission in 1944 Company Background S-92 helicopter has four blade, twin engines with a medium lift - Used for search and rescue S-92 aircraft elements need monitoring: - gearboxes, control systems, rotor blades, powertrain element The Problem Wired sensors have several inefficiencies: - The components are heavy - The wires break - The connectors fail - Slip rings are needed for rotating components The Problem A wireless sensor network is a possible solution to the problems of a wired system. Benefits of a Wireless System: - No long, heavy wires - No slip rings - Overall weight of system reduced The Problem Challenges of a Wireless System: - Powering system - Large Temperature Range -65ºF to 400ºF The team’s goal is to find solutions to these challenges through research and testing. The Problem Figure. An interior sketch of the tail rotor gearbox on the Sikorsky S92 Helicopter. The Problem Figure. Exterior view of the tail rotor, (where the electrics cavity is located). System Requirements The team must complete the following project requirements: - Monitor the bearing: Temperature, Vibration, or Strain Process the measured data: - Fast Fourier Transform (FFT) or Band Pass Filter (BPF) - Digitize and compress the data for storage Temporarily store the measured data Transmit the data to a stationary system for long term storage and analysis - Data must travel wirelessly upwards of 40 feet System Requirements Provide power to the measurement system and to the transmitter and receiver Figure. Illustrates the anti-bearing end of the electronics cavity. Access is provided here. System Requirements Electronics Compartment: - Size: 1.5” diameter x 5.1” long - Temperature Range: -65ºF to 300ºF Sensor(s): - Minimum of 2 sensor types - Temperature Range: -65ºF to 400ºF Rotating Speed of Tail Rotor Shaft: - 1200 RPM System Requirements Battery Life: - 1 year min (3 years recommended) - Must run for 12 hours a day and survive a 30 day period of inactivity Energy Harvesting - Thermoelectric (Thermocouple) - Vibrational (Piezoelectric) - Magnetic (Alternator) System Requirements Environmental Parameters: - Exterior hostile environment (maintain system internally) - Cavity is lubricated with oil - Moisture expected - High vibration level expected 2012-2013 Team Design Accelerometer, microcontroller, transceiver, and lithium battery mounted in the electronics compartment - One sensor - Signal quality needs improvement - Some components in need of replacement Mounted on lathe-like test rig - Bearings need replacement 2012-2013 Team Design Figure. Test Rig from 2012-2013 team. 2012-2013 Team Design Figure. System block diagram from 2012-2013 team. Project Goals ECE: - Sensor selection (at least two different sensors) - Signal analysis, storage, and transmission - Ensure sufficiently clean signal - Battery selection and power management ME: - Energy harvesting/energy generation to power/recharge system - Repair and improvement of last year’s test rig - Mounting and installation of sensors and transmitter Project Goals Figure. General block diagram for 2013-2014 redesign. 6 Period Highlight: Plan Actual % Complete % Complete (beyond plan) Actual (beyond plan) Timeline Semester 2 Semester 1 February ACTIVITY PLAN PLAN ACTUAL ACTUAL PERCENT START DURATION START DURATION COMPLETE September 100% 1 4 1 4 Research 2 10 2 5 Design 8 7 Component selection 12 3 Purchasing 13 3 Prototype Build 16 8 Testing 24 5 Debugging 28 5 Final Presentations 32 4 10% November December March April January Weeks 1 Project Statement October 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 Budget Budget funds from Sikorsky: $2,000 Re-use Mechanical components from last year. Estimated Electronics costs from last year’s expenses: $2,129.36 Budget deficit: $129.36 Mission Questions Which sensors should be used? Will data processing be accomplished at the transmitter or receiver end? Which energy harvesting technique will be best for this application? What is the power envelope of the full electronics package? Can we deliver that power through energy harvesting? Questions? Please vote with your iClicker based on the three criteria: - Grade: A, B, or C