Configure - Sierra Monitor

advertisement

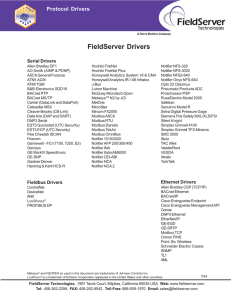

Interfacing Building Automation Systems (BAS) to Process Control Presented by: Gordon MacLachlan (Mac) Presentation Highlights The Need for BAS In Process Control Systems The Need for Process Control in BAS Systems Common BAS Network Protocols Common Process Control Network Protocols FieldServer Protocol Support FieldServer Hardware Solutions Case Study: Interfacing with Rockwell General Integration Considerations The Need for BAS in Process Control Energy Management • Process Control and BAS equipment interact to minimize energy requirements • Example: Different cooling schedules for a building when plant is in or out of operation Safety • Process Control Events could trigger safety actions on the BAS side and vice versa. • Example: Gas leak detection could close room vents in affected zone. Centralized Control • Centralized operations lead to the desire for homogenous host HMI’s that monitor both BAS and Process control. The Need for Process Control in BAS Optimized Environmental Control • Control Process affect the building environment. Monitoring the process allows for predictive zone management. Shared technology • BAS makes use of many of the same types of equipment that Process Control does. • Examples: Boilers, UPS systems, VFD’s etc. Common BAS Networks Open Protocol Networks • BACnet • LonWorks • Modbus Common OEM Networks • • • • JCI Metasys N2 Data Aire Carrier Lutron Fire Alarm Control Panel (FACP) Networks • • • • • Notifier EST Simplex Siemens Fike, and others Common Process Control Networks Open Protocol Networks • • • • • • • Modbus/TCP Modbus RTU OPC ODVA EtherNet/IP DeviceNet Profibus Hart Common OEM Networks • • • • • AB AB AB GE GE CSP DF1 ControlNet SNP SRTP CASE STUDY: Rockwell Interface Deciding on a Protocol – Factors that count Legacy PLC/SLC, or “Logix”? • If ControlLogix, then use SlotServer Is the serial DF1 port in use? • If so, then rule out DF1 as an option Does the specification state protocol to be used? • If so, then decision is made Cost of PLC equipment needed for the interface • Price differences may be significant. Client or Server Application? • For HMI Interface, use OPC. CASE STUDY: Rockwell Interface The ControlLogix Solution: SlotServer Direct connection from Allen Bradley ControlLogix PLC to another network Standard 1756 format plugging directly into the Allen Bradley ControlLogix rack RS-485 port for devices/networks using RS-485 protocols Ethernet port for Configuration Utilities & Ethernet devices/network LonWorks TP/FT-10 interface Standard LonWorks TP/FT-10 interface for LonWorks devices/network Installing the SlotServer module is a very simple procedure Ethernet port RS-485 port CASE STUDY: Rockwell Interface SlotServer Features Plug the SlotServer directly into the ControlLogix Communications rack Scrolling text display with 3 status LED’s provides card status at a glance A bank of six LED’s provides communications status at a glance, as well as additional diagnostic indications Ethernet port for advanced troubleshooting purposes Service Pin for LonWorks commissioning Diagnostic displays Service Pin CASE STUDY: Rockwell Interface Hardware Specifications: Backplane Load: 0.6A Slot width: 1 Operating Temperature: -40 to 185 Deg. F Humidity: 5-95% (non-condensing) CASE STUDY: Rockwell Interface Software Features Transfer up to 6000 points between ControlLogix and many third party interfaces. Configure the SlotServer to communicate with many different protocols, including LonWorks, BACnet, Metasys and Modbus. Flexible configuration architecture allows for creative connectivity options. Use the Standard SlotServer profiles for connection without configuration CASE STUDY: Rockwell Interface Software Features Control communications in the ControlLogix software using standard generic message blocks Example message block code provided in an ACD file with the SlotServer CASE STUDY: Rockwell Interface Distinct Advantages SlotServer Allows connection of a Third Party Network to a ControlLogix system without the use of external gateways Sits in the ControlLogix rack, thereby preserving cabinet “Real Estate” Provides generic profiles (such as LonWorks Open Interface) or custom profiles (with configuration), allowing for a choice between ease and flexibility. CASE STUDY: Rockwell Interface Generic vs Custom Mapping SlotServer can ship default with generic open profile or can be shipped as the configurable version. The generic profile eliminates the need for messing with config.csv, thus reducing commissioning time. Creating a custom profile with config.csv allows for more flexibility to suit the specific application FieldServer offers custom profiling services if needed. CASE STUDY: Rockwell Interface Preparing for Configuration 1. 2. 3. 4. Training – Attend a FieldServer training class or order the first SlotServer pre-configured as a template to learn from. Input – Acquire information about BAS protocol points to be mapped. Information must include point address details for the particular protocol. Draw – A picture paints the proverbial 1000 words. Sketch a network diagram, and then sketch a schematic of how the data blocks are to be mapped. Configure – With the first 3 steps done correctly, this step becomes easy. CASE STUDY: Rockwell Interface SlotServer Data Transfer over IO Data Image Logix CPU SlotServer Input Data Image Controller Tag Local:Slot:I:Data External Device eg. LonWorks Modbus Input Data Metasys In [0] Input Data Multiplexer Offset Description 0 Protocol Type 1 Node Status 2 Data Block Number 3 Reserved In [1] In_1 In_2 In_3 In_4 .. In_25 In [24] Data Arrays. Map Third party points into and out of these data arrays and let the Logix driver do the rest. 4 Output Data Image Controller Tag In_x Data ... Output Data 79 Out [0] Output Data DeMultiplexer Local:Slot:O:Data Offset Description 0 Protocol Type 1 Node Status 2 Data Block Number 3 Reserved Out_1 Out_2 Out_3 Out_4 .. Out_25 4 ... 79 Out_x Data Out [1] Out [24] Multiple blocks exist so that the data can be mapped through the limited IO Buffer on the backplane using multiplexing. CASE STUDY: Rockwell Interface Example: Connecting the SlotServer to LonWorks Sample Mapping: The points below show a sample of Lon Points that are mapped into the Data Arrays that get multiplexed in and out of the Backplane buffers. Map_Descriptors Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Lon_Function, Function, Node_Name, SNVT_Type nvoVolt1_25 ,Out_25 ,74 ,NVUOIMX ,WRBX ,Lon_Srv_1 ,SNVT_volt nvoVolt2_25 ,Out_25 ,75 ,NVUOIMX ,WRBX ,Lon_Srv_1 ,SNVT_volt nviAmp1_01 ,In_1 ,00 ,NVUI ,Server ,Lon_Srv_1 ,SNVT_amp nviAmp2_01 ,In_1 ,01 ,NVUI ,Server ,Lon_Srv_1 ,SNVT_amp Data Arrays Assigned to I/O Buffers by Logix driver Standard LonWorks Driver Mapping General Integration Considerations Are you a BAS expert or a Process Control expert? • Bridging between industries probably means that the user will be familiar with one side of the gateway application, but not the other. Some familiarization with the unknown side will be required. General Integration Considerations Different Protocols behave differently • LonWorks has binding, BACnet autodiscovers, EtherNet/IP talks tags, Profibus needs gsd’s, whereas ControlNet needs eds’s. Metasys has slaves, Modbus polls, GE EGD has subscribers, etc, etc.. • The bottom line is they all do the same thing in different ways. They all pass data. • Configuring these protocols is typically easy due to tools provided. However, knowing what to configure is not. General Integration Considerations Scaleable support – Use what you need • Using a FieldServer product requires purchase, configuration, commissioning and support • If familiar with the network protocols involved consider purchasing the product and doing configuration and commissioning yourself • If unfamiliar with the network protocols, consider purchasing the configuration • If unfamiliar with network integration, consider purchasing the commissioning. General Integration Considerations Getting it right – Input is the key • GIGO – Garbage in, garbage out - GUARANTEED • To configure a FieldServer product, details of the data to be mapped is required. This is the configuration input. • The quality of the configuration input determines the quality of the configuration, which in turn determines the success of the commissioning process. • The bottom line: Spend more time getting the input right. Resources FieldServer Website (www.FieldServer.com) LonMark website (www.LonMark.org) Modbus IDA website (www.modbus.org) Echelon Website (www.echelon.com) Rockwell Allen-Bradley Website (www.ab.com) BACnet Website (www.bacnetinternational.com) Rockwell Automation Encompass Website (www.rockwellautomation.com/encompass/) Contacts Marketing and Sales: Steve Ferree: sferree@fieldserver.com Richard Theron: rtheron@fieldserver.com Technical: Mac: mac@sfintegration.com THANK YOU! …..for taking the time to attend this presentation. Questions?