Asia - Teledyne Test Services

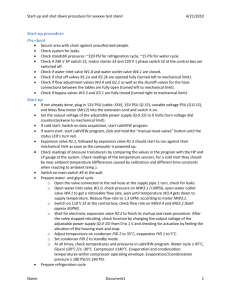

advertisement

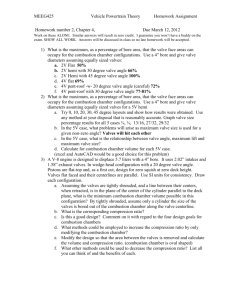

Introduction Testing Valves in Asia Fifth Annual QUIKLOOK Users Group Meeting Stock options are overrated …. China – 12 Plants under construction – All Westinghouse AP1000 (Advanced Passive) – 50% less safety related valves – 80% less piping – 85% less cable – Haiyang Site 6 reactors – Sanmen Site 6 reactors – About 16,000 megawatts total China – Westinghouse did a technology transfer to the Chinese for AP1000 – Signed contract with Westinghouse – Cannot market the AP1000 outside of China – Scaled up the AP1000 to AP1400 – Marketing AP1400 outside of China Conceptual View AP1000 Taiwan – Lungmen Nuclear Power Plant – GE ABWR (second built, first is in Japan, biggest nuclear plant in the world) – 2 units 1350 megawatts each – Fuel load planned for April 2012 (Unit 1) – 9.2 Billion USD (may never start) – 4 years behind schedule ABWR Reactor Lungmen/GE valve spec specified stem mounted strain gages on all safety related MOVs – Lungmen plant has 400 safety related valves – 200 per unit – No valve testing required prior to shipping valves to Taiwan Westinghouse spec for valves in China included diagnostic testing prior to shipment – For MOV – For AOV – For BOP The spec was tailored for stem mounted strain gages – QSS – SMARTSTEM China / Taiwan – Waited to perform diagnostic testing – Basically waited for US to do the research – Then wanted testing done for ½ price Taiwan – Does lots of valve and actuator maintenance – Based on schedule – Maintenance work quality is poor – Use incorrect grease – Don’t do many stem lubes The first 4 units (2 at each of the China sites) big valves were procured by US valve companies – Flowserve – Velan – Weir The big contract went to Flowserve – Gates – Globes – MSIV The remaining new plants in China – Most valve contracts went to in country companies • Shentong Valve (own Quiklook) • Sufa • Shenjiang Valve (will purchase) – US companies bid but can’t compete • Valves built in China are low quality • Use cheap actuators • They don’t understand weaklink • Required thrust determination is not standard Roger and I hosted a seminar in China last year and invited: – Flowserve – Automatic Valve – Top Works – Curtis Wright (EGS connectors) Teledyne has signed up a China Distributor – Chance Development (H.K.) Limited – They are pushing Quiklook/QSS in China – Company President is former Nuclear employee Velan – Had Quiklook for a number of years Flowserve – Bought Quiklook in 2009 Weir – Bought Quiklook in 2010 Taiwan Power – Using Quiklook since 1994 China Valves (AP1000) – All valve tested static and “DP” before shipping – 20 to 30 strokes required per valve – Reduced and nominal voltage – Actuator sizes are very conservative – All SR MOVs are DC – BOP all AC SMB-3-150 on an 8” gate valve (Flowserve) 36” MSIV Gate Valve Taiwan Power Company – Teledyne awarded contract for AOV Program (Turn – Key) • Design Basis Calculations • Weaklink Analysis • Static Testing • Dynamic Testing Used ACE 3.0 Used ACETest Used Quiklook AOV Scope – 68 valves – 68 static tests – 6 dynamic tests TPC I/C Staff – Very limited valve experience – Do not understand testing – They kept asking me about torque switch settings?? TPC is slowly adopting how we do business Just began using safety glasses/shoes Use pre-job briefs – Called TBM – Tool Box Meeting The TBM …. First time TTS used Windows 7 for the Quiklook operating system XP software difficult to obtain Future system will use Windows 7 Discovered weakness with I/P circuit New board is in Engineering Valve population included – 9 Fisher actuators – 25 Automax for quarter turn valves – 34 Valtek Valves were very high margin Most valves have no regulators Full air pressure – Actuator nameplate indicated 100 psi max – Measured 120 psi Valve Pics - Automax Valtek (on-off) Fisher – 3-Way Control Valve MSIV in DW Testing with QLII Intake Structure Questions?