PPT

advertisement

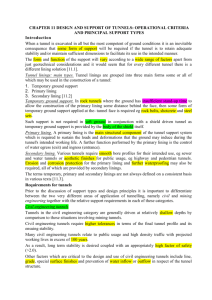

The fifth China-Japan Joint Seminar for the Graduate Students in Civil Engineering AN OVERVIEW ON THE TECHNOLOGY OF HIGH SPEED AND NON-DESTRUCTIVE INSPECTION OF HIGHWAY TUNNEL LINING DEFECTS H. Liu, X. R. Liu & X. Y. Xie Geotechnical Department of Tongji University, Shanghai, China OUTLINE 1 Introduction & Requirements 2 Existing Techniques Examined 3 Methods Suitable for the Topic 4 Conclusions & Outlook 1 INTRODUCTION & REQUIREMENTS 1 Introduction Mountain highway tunnels suffer from great external rock pressure, seismic load, and concrete deterioration. Furthermore, differing from onground structures, their design conditions vary case by case. So it is common to find deformation, severe leakage, big cavities, cracks and other lining defects after the tunnels are put into usage. Rock pressure Seismic Concrete load deterioration Varying design condition Mountain Highway Tunnel Deformation Leakage Cavities Cracks 1 Introduction 1 Introduction How to detect all these lining defects Manual methods geophysical surveys Slow fast destructive Non-destructive imprecise What are requirements accurate 1 Requirements The aim of non-destructive testing methods is to obtain complete, reliable and reproducible data on the state of the entire highway tunnel lining. Requirements 1 Essentially non-destructive 2 Examination at any point 3 Used in different tunnels 4 Not be influenced by installations 5 High traveling speed 6 Resistant to vibrations and operate in different climate 7 Established accurate defective zones 8 Results should be available immediately 2 Existing Techniques Examined 2 1 Mechanical Oscillation Techniques Structural dynamic methods Seismic reflection and refraction 2 Existing Techniques Examined Measuring the response to an artificially induced vibration Microseismics and sonic emission analysis Ultrasonics--reflection and indirect surface transmission Radiation Techniques gamma ray backscatter neutron backscatter determine the density and moisture content 2 3 Electric and Electronic Techniques eddy current methods 4 Existing Techniques Examined ground penetrating radar electrical potential methods Optical Techniques infrared thermograph Multi-spectral analysis CCD digital camera 2 Existing Techniques Examined Discussion Advantages and disadvantages of various techniques Techniques Main Application Value Structural dynamic methods (direct vibration) Bridges; Aboveground buildings Seismic reflection Geological investigations; determination of layer thickness Low Micro-seismics and sonic Emission analysis Coal mines; laboratory tests Very low UItrasonios-reflection and indirect surface transmission Steal construction; Mechanical engineering; pipelines; tanks Gamma ray backscatter Road construction, Earth construction; investigation of moisture content and density Mechanical Oscillation Techniques Radiation Techniques Neutron backscatter Very low Problems With Uneven wall thickness; rock in homogeneity; varying ground water level Accuracy; speed Reproducibility; accuracy Advantages None Only connected with very large cavities behind the tunnel lining Investigation of structure-bome noise Very low Coupling to test ground, concrete inhomogeneity; speed of diffusion by aggregates; accuracy None Very low Speed; penetration depth None Low Speed, penetration, depth Indication of moisture content point-by-point 2 Existing Techniques Examined Advantages and disadvantages of various techniques Techniques Electric and Electronic Techniques Optical Techniques Main Application Value Problems With Advantages Eddy current methods Electricity conducting metals; crack detecting for pipelines, indication of reinforcement Low Speed, non-conducting materials; penetration depth. Indication of reinforcement Georadar Ground investigation of bridges and tunnels High Evaluation; reflection by metallic cladding; speed Good penetration depth Electrical potential methods Detection of corrosion of reinforcement Low Speed; penetration depth Detection of corrosion Infrared thermography combined with visual determination Check of thermal insulation; tunnels Very high Certain tunnel climates; evaluation; heat release of installations Detection of cavities and moist patches, cracks, etc.; high speed CCD digital cameral Inspection of structure surface high Illuminator; Measurement algorithm Detection of cracks; High speed Georadar Infrared thermography CCD digital cameral 3 Methods Suitable for the Topic 3 Ground penetrating radar (GPR) CCD digital camera Infrared topography Methods Suitable for the Topic 3 Methods Suitable for the Topic GPR Operating principle: used in reflection mode. high-frequency electromagnetic wave emitting antenna receiving antenna interfaces the reinforcing steel bar defects in the lining GPR has been popularly used to detect the tunnel lining, and it can detect the crack, leakage and cavities behind the lining. 3 Methods Suitable for the Topic CCD Camera CCD Camera is widely used for the inspection of structural surfaces, especially the crack detection of tunnel lining. Operating principle: Power supply Illuminator Tunnel Optical device CCD Camera Image processing system Image analysis system Crack map Image acquisition system Information of crack Data storage 3 Methods Suitable for the Topic Infrared topography Operating principle: Infrared topography makes use of thermal radiation, which is radiated by every surface. A thermal flow can be created through a current of gaseous material or a liquid material. Points affected by such thermal flows are generally characterized by a pronounced increase or decrease in temperature, in comparison with their surroundings. In this way, possible damage in the tunnel lining can be determined through the use of infrared topography. moist patches mainly Identify water seepage 4 Conclusions & Outlook 4 Conclusions & Outlook GPR Cracks and cavities behind the lining CCD camera Defects (crack) on the surface of the lining Infrared topography moist patches water seepage integrated inspection car Thank you!