hot-tap and stopple plugging system

advertisement

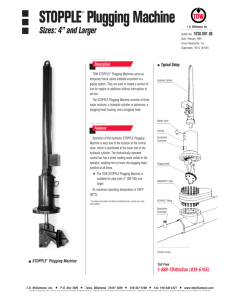

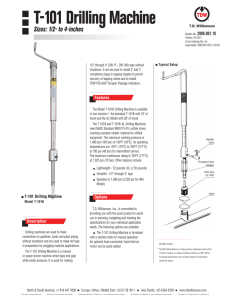

PLAN PRESENTATION ABSTRACT T.D. WILLIAMSON “HOT-TAP AND STOPPLE PLUGGING SYSTEM” for modification of repair of pipelines without shutdown or loss of production • INTRODUCTION This system has been devised and developed by T.D.Williamson Inc. to enable pipeline operators to carry out maintenance, modifications and repairs on a planned basis without the need to consider the effects of interrupted throughput or loss of production. • Generally, the system enables large savings to be made on initial installations also, because it avoids the need to install valves etc., at points where possible future additions might be necessary. • The location of pump or compressor stations, and subsequent activities such as road or rail constructions, or other civil engineering works of a major nature need not be compromised, as it is relatively simple to relocate the pipeline or make any other changes necessary without interrupting operations • The initial cost of the system is extremely low compared to the savings made – for example the loss of revenue due to a shut-down of a major gas pipeline operating at high efficiency, would normally pay for the cost of the system in less than 24 hours – and this period of time is unusually short in terms of the time normally required for a shut-down. • Many major gas and oil pipeline operators have also recognized the system as an invaluable safeguard in terms of their contractual commitments to guarantee supplies to their customers – such guarantees often incurring penalties far in excess of the cost of this system for even relatively short interruption of supplies. • Tapping is the precise process of drilling a hole in an on-stream piping system without spilling its contents or interrupting its flow. Over the decades, TDW Services, has performed thousands of successful hot taps onshore and offshore and in nearly every type of pipeline material. Piping systems are designed to move liquids, gases or other products in a continuous flow. Shutting down these essential systems, or even portions of them, can be extremely costly and time consuming. When alterations or repairs are required in live systems, TDW Services will handle your assignment from concept to completion, whether the operation calls for common taps, side taps, angle taps, tank taps or custom designed applications. PROCEDURE FOR HOT TAP AND STOPPLE PLUGGING PROCEDURE FOR HOT TAP • A fitting is permanently secured to the line by welding • A permanent valve is installed on the fitting • A TDW tapping machine is installed on the fitting, and the valve is opened. After pilot drill penetrates, the tapping machine fills with product, and air is purged from the housing. The tap is made through the line and the coupon is retained • The valve is closed, and the tapping machine is removed. A branch connection is added, and the valve is opened. The new connection is ready to put into service. This field-proven TDW procedure is quick and precise. Split Tee fittings are supplied in two pieces which are clamped and then welded to the outside of the pipeline while the flow continues in the line. (Welding on the outside of pipelines under pressure has been carried out for many years and has been the subject of satisfactory studies conducted by major research organizations including the Battelle Memorial Institute, American Petroleum Institute, British Gas Corporation (Research) etc SLIDE SHOWING WELDING OF SPLIT TEES Temporary Sandwich valves are then installed on the fittings and special “Tapping Machines” are used to cut holes through the pipe wall SLIDE SHOWING TAPPING OF 2” EQUALIZATION HOLE WITH TM T101 The piece of pipe cut out, is retained inside the cutter and withdrawn SLIDE SHOWING COUPON AFTER HOT TAP A temporary bypass is fitted and the Stopple Plugging Machines are placed in position SLIDE SHOWING STOPPLE PLUGGING IN The Stopple Plugging Machine lowers the “plugging head” into the pipe completely isolating the section and diverting all flow into the temporary bypass SLIDE SHOWING PLUGGING HEAD IN POSITION When the modifications or repairs are complete, a special plug is locked into the top of the fitting so that the valves can be recovered SLIDE SHOWING A SECTIONAL VIEW OF THE PIPE WITH LOR IN PLACE Blind flanges are installed to complete the job. Safety and Quality are of prime importance in all T.D.WILLIAMSON products. All designs undergo complete strain gauge analysis and every component is thoroughly tested before leaving the factory. Operators are trained by qualified WILLIAMSON Engineers and technical advice and equipment maintenance procedures are available. SLIDE SHOWING STRAIN GAUGE IN USE After the isolated section is emptied, the line can be cut and the modifications or repairs carried out. SLIDE SHOWING THE PLUGGING HEAD IN POSITION PROCEDURE FOR STOPPLE PLUGGING TYPICAL DOUBLE STOPPLE LINE PROCEDURE (USING FOUR FITTINGS AND A BYPASS) A TDW plugging machine can temporarily stop the product in an operating pipeline, by acting as a block valve. When used in conjunction with a bypass line and another plugging machine, product can be rerouted around the isolated section of pipeline, while repairs, alterations, relocations and instrument installations are made to the piping system. SLIDE SHOWING TYPICAL DOUBLE LINE PROCEDURE – USING FOUR FITTINGS AND A BYPASS • The four fittings are permanently secured to the line. • Temporary SANDWICH valves are installed on the fittings, and taps are made through the valves. • Two STOPPLE Plugging Machines are installed. Product is diverted through the temporary bypass. The isolated section is purged. Modifications are made to the isolated pipe section. The new section is purged and equalized, and the plugging heads are retracted. • The temporary bypass is removed. LOCK-O-RING Plugs are installed in the STOPPLE Fittings with a tapping machine. All equipment is then removed, and blind flanges are installed on the fittings to complete the job.