Collaboration in the aerospace supply chain - ICPS

advertisement

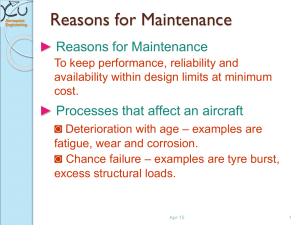

Collaboration in the Aerospace Supply Chain - Towards the Extended Enterprise Bangor University Wednesday 28th March 2012 John Whalley Aerospace Wales Forum Ltd. www.aerospacewalesforum.com Aerospace technology is expensive Pound for Pound by weight an aero-engine has the same value as silver Pound for Pound by weight a motorcar has the same value as hamburger Map of Wales and key sites Aerospace Wales Forum Established 2002 150 member companies Representative body for aerospace & defence National partner in Wales of the UK’s trade association ADS (Aeronautics, Space, Defence & Security) Closely linked with other UK regional bodies Close partnership with Welsh Government Facilitates marketing, international partnering and company development www.aerospacewalesforum.com The Industry – Size & Scope £5 billion pa sales ($8US billion) Over 160 companies 25,000 directly employed Presence of leading companies: - EADS Cassidian, BAE Systems, General Electric, General Dynamics, Raytheon, Hawker Beechcraft & Airbus SC21 – a UK aerospace supply chain initiative SC21 – launched at the Farnborough International 2006 Brought together a number of streams of development: – Aerospace innovation and growth team (AeIGT) – SCRIA – Lean Aerospace Initiative (LAI) – DTI initiatives – SBAC Quality Committee – Company (industry) supplier development programmes – Regional Associations and Groups Why SC21? • Customers demanding more affordable and innovative solutions • UK supply chains need to be more competitive • Primes/OEMs want fewer direct suppliers • UK industry recognition that transformation/rationalisation is required • Defence Industrial Strategy (DIS) Why SC21? • Improvement and competitiveness is dependant upon companies working together to: – Increase efficiency – Remove repetition and duplication – Plan and communicate better • Earlier in the life-cycle • Longer term – through life 21st century supply chains led by • • • • • • • • • • • • • • • • • • Airbus Agusta Westland BAE Systems Bombardier Aerospace Cobham Darchem Freeman & Proctor GKN Goodrich Lockheed Martin Marshall Aerospace Naysmith Group Rolled Alloys Rolls-Royce Selex Smiths Thales Ultra Electronics who committed to • Fundamental business transformation • Accelerated Change and Continuous Improvement. • Through life management • Demonstrating SC21 commitments • Leadership role The commitment • Three key action streams to drive transformation and improvement – Better supply chain relationships • Share selection rules based upon through lifecycle costs / affordability • Supply chain collaboration, sharing best practice and driving innovation • Use SCRIA code of practice and toolsets to companies and suppliers – Better supply chain development and performance • Remove duplication of supply development programmes – achieve 80% commonality • Develop common metrics (KPIs) – target 80% common – Reduce auditing through recognition of supply chain accreditation • Recognise and accept accreditation to AS/EN9100 • Support special processes approval to Nadcap What is SC21? - SC21 scope 1. accreditation: need to remove repetition, and unnecessary duplication 4. innovation 3. relationships: initially SC21 will implement 3 action streams to drive early transformation and improvement 2. development and performance: need increased efficiency and remove waste 5. need for better end-to-end communication and collaborative planning through life capability management Collaboration in Defence – Alliancing – BS11000 MARS – Military Afloat Reach & Sustainability North West Aerospace Alliance ASCE Programme Extended Enterprise Shared Services Work Share Commodity Groups Shared benefits Supplier Common strategy Associations ASCE Shared objectives Common language Common processes Common culture Composites CG Complex Machining CG Process Treatments CG Commodity Groups Robotics, Automatio n & Tooling CG Design & Engineerin g CG Autonomous Systems Commodity Group launched in July 2011 and runs parallel with GAMMA SME Machining CG NWAA Extended Enterprise – Current State Required Capabilities Clients Risk sharing Design to deliver 25 -30 year Contract Turnkey Solution Providers No current North West Candidat e Contract Supply Chain Financially robust Multi-materials Single point responsibility Evolve with project life North West Supply Chain disadvantaged Manage the supply chain With no current NW RSP the Supply Chain could be starved of 17 future work – if we don’t respond! NWAAExtended Enterprise- Future State NWAA Extended Enterprise Model 1 2 Process Treatment Autonomous Systems SME Complex Machining Composites (Commodity Groups) Extended Enterprise 1 Design & Engineering Robotics, Automation Tooling 2 Commodity Groups and Commodity Group companies interact, collaborate and bid collectively 4 3 2 Comp[ex Machining 1 3 1 2 2 Work Package Bids 1 Extended Enterprise future state - suppliers from a cross sector of Commodity Groups bid collaboratively to provide through life (design and build) capability Initial Lead Partner Alliance - Structure looks something like this … … End Client Contractual Link A Lead Horizontal & Vertical Collaboration Vertical Collaboration . Horizontal Collaboration . Sub Partner 1 NWAA as ‘honest broker’ Partner Sub Partner 2 • • Sub Partner 3 ? • • selection open book build up (& auditing on expenditure) dispute resolution development The Future? Aerospace Growth Partnership Continued growth in population and trade Growing environmental and resource pressures “Limits to Growth” Growing opportunities and competition New solutions A global business built on global teams Aero 2075 – Flying into a bright future? Thank you for listening Any questions? www.aerospacewalesforum.com