D&C PT Contractor`s Role & Responsibilities

advertisement

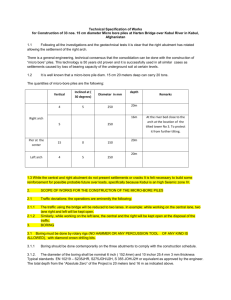

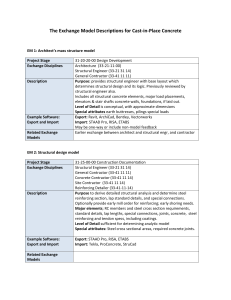

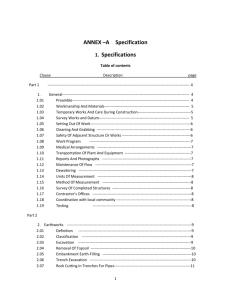

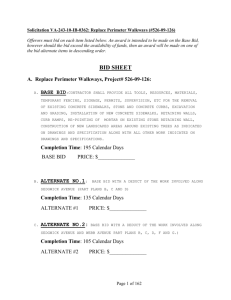

D&C PT Contractor’s Role & Responsibilities Chris M. Harris Contracts Manager, Structural Systems & PTIA Technical Committee Introduction • Why do PT contractors get involved in the design of the project to start with? • What are the common efficiencies introduced to the structure by a PT contractor? • Integration of the PT contractor into the design team. • What aspects of the existing design will the PT contractor review/change • Examples • Conclusion Why do PT contractors get involved in the design of the project to start with ? • Commercial desire • Specialist engineers, design draftspersons, & design software • Risk & reward allocation • Time • Constructability What are the common efficiencies introduced to the structure by a PT contractor ? • • • • Element thicknesses Support optimisation Slab structure type optimisation & formwork Reinforcement rationalisation Integration of the PT contractor into the design team. • • • • • Definition of structure performance Documentation status Coordination Design Program Certification What aspects of the existing design will the PT contractor review/change? • • • • • • Depends on the type of project Ieff / Igross (for buildings) Concrete grade / volume / thickness Structure type (flat plate / flat slab / banded) Restraint design Rebar content Eureka Tower • Conforming design • Reinforced slabs Eureka Tower • Non conforming design • PT bands and slabs • Driving force TIME Conclusions • Project Engineers to coordinate with contractors • Involve a PT contractor early PT in buildings PT is likely to be considered for most projects. If the consultant doesn’t consider it, then the contractors will Why PT? • Savings in materials • Savings in construction time • Improved durability and robustness • Cost savings Some perceived down side issues • • Time consuming to design by the occasional designer ? PT applies real force into a structure hence analysis (incl. secondary effects) needs to be realistic and specific. Some perceived down side issues • System and process needs to be understood and details coordinated sufficiently • Finding most economical proportions of concrete, PT & reinforcement can be a lengthy iterative process, but usually yields substantial benefits. Software & experience is key. Other effects to consider • Secondary effects in all indeterminate PT structures, but can be beneficial • Structural movements (creep, shrinkage, thermal) • Structural restraints (walls, stability elements) • Dynamic behaviour (may be a lighter, livelier structure) If doubt exists, talk to a specialist PT designer (or the PTIA) PT design is not different however... • Effective & efficient design does require experience • With sound engineering knowledge and practice this can be done successfully. • Assistance and guidelines can normally be obtained from the specialist contractors Design philosophy • Consider the general concept of partially prestressed concrete • Appropriate proportions of reinforcement and prestressing steel depends on the application (restrained v. unrestrained concrete) The D&C route for PT delivery The usual variants here are: • D&C by tender invitation • D&C by alternative design If D&C is expected and planned for, time efficiencies and innovations can occur D&C Design Brief A Post Tensioning Design Brief is critical for a successful D&C arrangement. It should focus on the performance requirements on the design The extent of D&C area required The loads and load paths Member sizes with acceptance tolerances Serviceability and durability requirements Movements and Jointing strategy Define the Design, certification & approval process Performance requirements As far as possible indicate: Architectural requirements (tolerances, finishes etc) Site constraints and constructability issues Pour sequence & any limitations on edge stressing access Limitations of the supporting structure. Any frame actions that need to be considered in floor design. Expected areas of restraint and strategy for its management incl. location & types of pour strips &/or temporary movement joints &/or permanent building joints. Roles and responsibilities in the design process Inspections and installation signoffs Quality and safety requirements. Types of PT Contract •Supply and Install (S&I) –Structural design, documentation, inspection & certification by engineer –Shop drawings, install, QA by specialist contractor •Design and Construct (D&C) –structural floor design, documentation by specialist contractor –Install, inspection & certification by specialist contractor –Engineer remains responsible for vertical elements, stairs, wind & earthquake design, etc. D & C Tender Information •Post Tensioning Price •Conventional Reinforcement Quantities •Concrete Properties and Profiles •Structural Design Criteria •Detailed Scope of Work •Client Responsibilities •Contract Conditions Design Considerations for PT Price •Pour Size •Strand Diameter •Number of Strands per Tendon •Couplers •Efficient Approval Process Concrete Properties and Profiles • Concrete outlines and grade needs to be provided with PT price for client to determine total cost of solution. • Be aware of concrete testing & strength requirements for initial & final stressing, these are essential for performance of concrete & safety at PT anchorages. Structural Design Certificate • • • • Loads Durability Requirements Deflection Criteria Analysis Assumptions Detailed Scope of Work • Design Deliverables for D&C, usually: – Concrete outlines – PT drawing (design & shop in one) – bottom reinforcement drawing – top reinforcement drawing – sections & details • Construction Services Client / Builder Responsibilities • • • • Site Amenities Supply of Power and Water Lifting of our Materials on to the Decks Supply and Install of Conventional Reinforcement including Studrails where applicable • Concrete Infill of Top Surface Stressing Pans • Anything else (job specific) Contract Conditions • • • • • • • Reference to Standard Conditions of Contract Reference to EBA Variation Rates Payment Terms Retentions Liquidated Damages Insurances Project Relationships Developer Architect Structural Engineer Head Contractor Post Tensioning D&C Subcontractor Formwork Sub-Contractor Reinforcement Supplier Steel Fixer Concreter Timely Co-ordination Co-ordination between: •services consultants •architect •structural engineer •builder’s services (alimaks etc) all by others. Co-ordination between: •structural engineer •pt design shared by engineer & specialist pt designer. Timeliness & information sharing is critical. Late information will lead to re-work & additional costs. Failure to co-ordinate will lead to re-work & additional costs. Acknowledgements John Fairweather Frank Filippone Jamie Mackenzie who are the authors of most of these slides. However any errors are mine.