Tungsten Carbide and Possible Military Applications David Brice

Tungsten Carbide and Possible Military Applications

David Brice: Department of Materials Science and Engineering, College of

Engineering and Honors College

Faculty Mentor: Peter Collins, Department of Materials Science and Engineering, College of Engineering

ABSTRACT

Tungsten carbide (WC) ceramics are extremely hard and exhibit great potential for use in military application. The purpose of this project is to show that tungsten carbide (WC) is a more effective material than Kevlar or steel when used for body armor. Tungsten carbide possesses a high measure of hardness that indicates a high resistance to deformation. Also, the methods of production, namely Pulsed Current

Activated Sintering (PCAS), can increase these natural properties. To conclusively prove that WC can be used as body armor components, the material must be tested by firing armor piercing munitions at samples of the material

RESEARCH QUESTIONS

Is tungsten carbide a reliable material to use in body armor?

I believe that tungsten carbide is an ideal material for body armor, capable of resisting direct bullet strikes.

LITERATURE REVIEW

Natural Properties

Tungsten carbide is a ceramic composed of two distinct elements: tungsten (W) and carbon(C). WC has an extremely high melting point of 2800 °C (Bauccio 1994), which indicates that the bonds between W and C are strong and stable, and require immense amounts of energy to break. The strength of the bond is evident when the material's hardness (the ability of a material to resist permanent change to its shape due to a force applied to it) is measured. The hardness of WC is 90 if using the Rockwell Hardness scale A (RHA) (Bauccio 1994). This measurement of 90 HRA is quite high, and when compared to carbon steel ,which has a HRA of 40, it becomes clear that tungsten carbide is superior. Tensile strength and compressive strength have been measured at 669x10 9

Pa and 2683x10 6 Pa respectively. WC's resistance to force exerted onto it indicates that it could withstand the strike of a bullet.

Methods of Production

Tungsten carbide begins as an ore (Ammonium Paratungsten). The common way to produce WC is to heat the ore to 900° C and mix it with carbon to produce a powder of tungsten carbide. In order to solidify the WC-Co powder, the ceramic must be compressed under pressure of 205x10 6 Pa (15 tsi) (Bowyer and Gall 1985, 25.18).

However, according to Shon In-Jin et al, the properties of WC can be increased by applying a process called pulsed current activated sintering (PCAS), which allows milled WC to reduce its grain size (Shon, In-Jin,

Byung-Ryang Kim, Jung-Mann Doh, Jin-Kook Yoon and Kee-Do Woo. 2009). The decrease in grain size leads to greater densification of the ceramic which in turn increases the properties of tungsten carbide, primarily hardness and toughness.

Experimental measurements

•

Experiments conducted with the intention of measuring spall strength through the Hugoniot Elastic Limit

(HEL) of Tungsten Carbide cobalt (G13 WC-Co) alloy. Study shows that WC-Co has high density toughness, hardness, and toughness, making it an ideal material for military applications.

•

Experimental setup consisted of a plate of WC-Co sandwiched between sheets of Mylar; sensor probes were inserted next and then covered on both sides with plates of Poly(methyl methacrylate) (PMMA).

•

Experiment consisted of firing projectiles onto the plates and measuring the effects they had on the tungsten carbide.

•

The data gained from the experiment suggests that WC-Co has higher spall strength 4.38 GPa (4.38*10^9 Pa) when compared to a similar ceramic WC-5Co, and HEL of 3.3 GPa

METHODOLOGY

In order to prove the superiority of tungsten carbide, an experiment was required to compare WC and current body armor materials such as Kevlar and steel plates. The experiment included the following steps:

1. Measure weight and dimensions of each sample to be used

2. Set up material in a firing range

3. Place pressure sensors on surface of material to be fired upon

4. Fire rounds of varying caliber at the material. After each strike, record data obtained by pressure sensor.

5. Weigh the sample that was struck by the bullet to measure any loss of mass due to spallation

6. Measure dimensions to measure any deformation

Note: The only drawback to using tungsten carbide is the weight. Due to tungsten carbide’s high density the material is quite heavy.

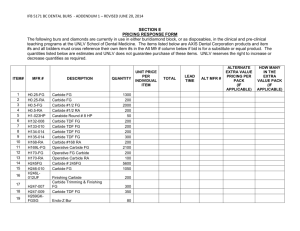

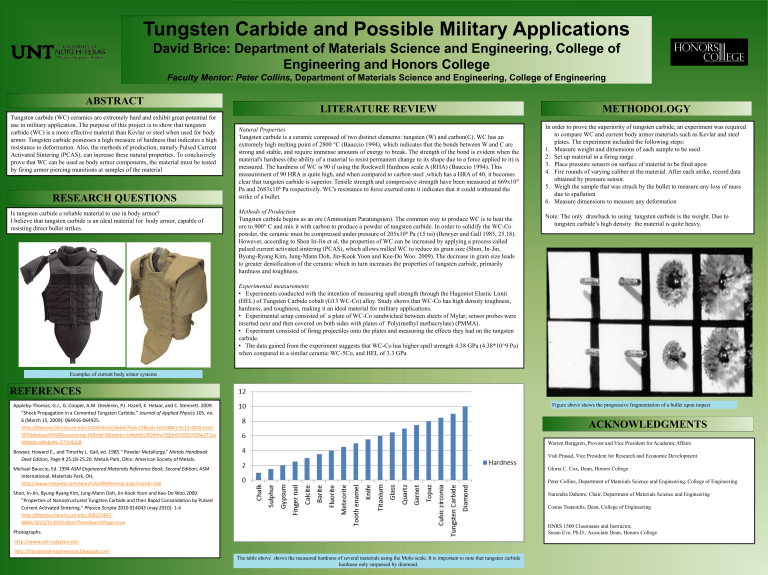

Examples of current body armor systems

REFERENCES

Appleby-Thomas, G.J., G. Cooper, A.M. Diederen, P.J. Hazell, K. Helaar, and C. Stennett. 2009.

"Shock Propagation in a Cemented Tungsten Carbide." Journal of Applied Physics 105, no.

6 (March 15, 2009): 064916-064925. http://libproxy.library.unt.edu:2104/ehost/detail?hid=13&sid=1cb248b1-9c12-40c0-bcaf-

907ddbdcae63%40sessionmgr15&vid=3&bdata=JnNpdGU9ZWhvc3QtbGl2ZSZzY29wZT1za

XRl#db=a9h&AN=37259328

Bowyer, Howard E., and Timothy L. Gall, ed. 1985." Powder Metallurgy." Metals Handbook

Desk Edition, Page # 25.18-25.20. Metals Park, Ohio: American Society of Metals.

Michael Bauccio, Ed. 1994 ASM Engineered Materials Reference Book, Second Edition, ASM

International, Materials Park, OH, http://www.matweb.com/search/GetReference.aspx?matid=166

Shon, In-Jin, Byung-Ryang Kim, Jung-Mann Doh, Jin-Kook Yoon and Kee-Do Woo.2009.

"Properties of Nanostructured Tungsten Carbide and their Rapid Consolidation by Pulsed

Current Activated Sintering." Physica Scripta 2010 014043 (may 2010): 1-4 http://libproxy.library.unt.edu:3082/1402-

4896/2010/T139/014043?fromSearchPage=true

Photographs http://www.udri.udayton.edu

http://hardmetal-engineering.blogspot.com

Figure above shows the progressive fragmentation of a bullet upon impact

ACKNOWLEDGMENTS

Warren Burggren, Provost and Vice President for Academic Affairs

Vish Prasad, Vice President for Research and Economic Development

Gloria C. Cox, Dean, Honors College

Peter Collins, Department of Materials Science and Engineering, College of Engineering

Narendra Dahotre, Chair, Department of Materials Science and Engineering

Costas Tsatsoulis, Dean, College of Engineering

HNRS 1500 Classmates and Instructor,

Susan Eve, Ph.D., Associate Dean, Honors College

The table above shows the measured hardness of several materials using the Mohs scale. It is important to note that tungsten carbide hardness only surpassed by diamond.