Process Shipper Engine - Pur

advertisement

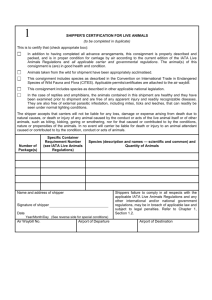

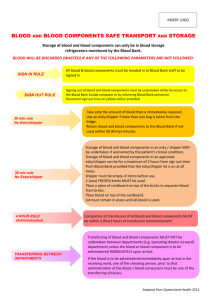

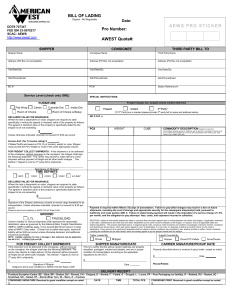

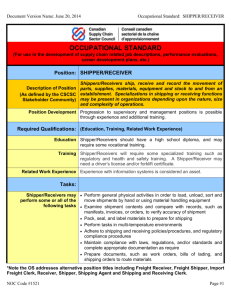

Improving the accuracy and efficiency of your shipping process Packing & Shipping Software SmartLinc’s… Process Shipper Engine® Company Information: SmartLinc, Inc. founded in 1997 Core competency custom shipping integration Hundreds of successful installations Carriers: UPS, FedEx, USPS, LTL’s, Couriers, Company Vehicles, Regional Carriers Pack verification and shipping software THE LATEST TECHNOLOGY Process Shipper Engine® Architecture Programmed in Microsoft.net C Sharp Installs behind the customers firewall Microsoft SQL database Integrates to small carriers through their web services Trued Web-Based Enterprise System •Installed on a server or a single PC •All processing is done at your site •Fully scalable (one station to 100+) •Integrated to client ERP or accounting system No software required to be loaded at the client workstation level. Interfaces Available via •Custom scripts •ODBC •File Link / Screen Scrape •Batch Link •TCP/IP Process Shipper Advantages True Web based solution using the latest technology Scalable from one to 100+ locations. No software required at workstation. Seamlessly integrates to WMS/ERP/accounting systems Savings on shipping costs offset any investment Automatic zone map/rate change/surcharge updates. No EOD manifest closing with parcel carriers One solution that handles small package, TL and LTL shipments Shipper logs into Process Shipper Sage 100 ERP Shipping by SmartLinc Password protected log in Shipper scans or enters shipment #1000 created from host system Scan barcode or type Transaction ID Information is automatically filled in from the host system “Ship To” data pulled over “Ship method” data Populated Line item detail filled in Shipper enters quantity for 1st box Two items packed in first box Scale is read, remaining balance displayed Items remaining to ship Click “Pack” to put items in carton After clicking “Pack”, items appear on right side Shipper packs the other two items in the 2nd box by hitting “Pack All” “Pack All” puts remaining items in second carton Shipper can request a rate shop or preselect “BestWay” Rate shop can be used in quoting orders in the sales department not just in shipping them. Process Shipper automatically prints shipping labels Process Shipper automatically prints the packing list Can include customer’s logo Includes line item detail and tracking data E-mail notification is automatically sent. It can include the packing list PDF. What items are in what box. Includes line item details Customer Service creates shipment record #1000 in host system Carrier data Order detail Destination data Shipper scans or enters shipment #1000 created from host system Scan barcode or enter transaction number Information is automatically filled in from the host system Ship via detail Delivery info. Line item detail Shipper enters quantity for first pallet Items being packed on to pallet Scale is read, remaining balance displayed Items remaining to be packed on pallet 2 3 Items moved to pallet 1 Click Pack button The remaining items are packed on the second pallet and the scale is read. “Pack All” puts remaining items on second pallet To rate shop Use LTL Rate Shop Process Shipper performs an LTL Rate Shop Rate shopping can save the shipper money while showing days in transit. The shipment is processed and the appropriate labels are printed with a barcode and the tracking number Tracking data The Packing List AND Bill of Lading are generated from Process Shipper. Saving Time and Guarantying Accuracy. Anyone can be an expert on producing a packing list OR Bill of Lading with Process Shipper E-mail notification is automatically sent. It can include the packing list PDF. Tracking data What items are on what pallet Host system is updated in real time including details such as: Tracking #, Freight cost, Carrier, Service level, Shipped by, Marked as shipped, Ship date & time, Actual quantity, # of packages etc. Shipment data updated Sage 100 ERP Shipping by SmartLinc Thank You