Presentation

advertisement

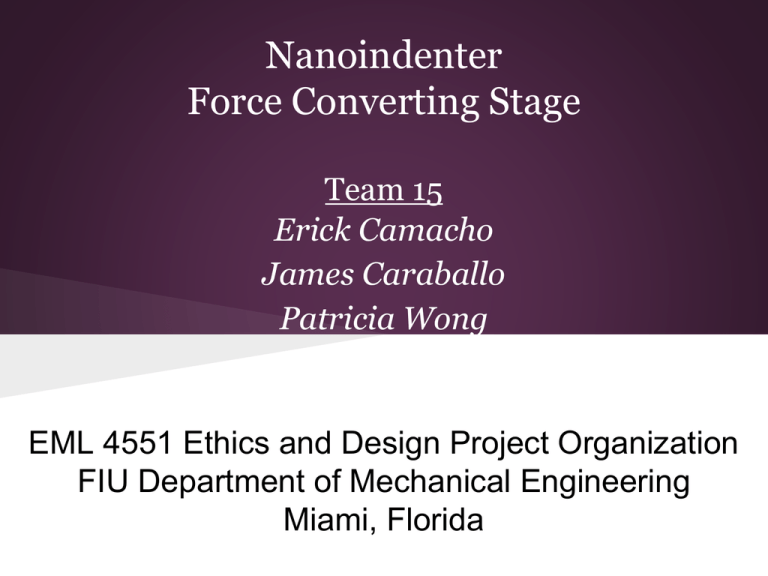

Nanoindenter Force Converting Stage Team 15 Erick Camacho James Caraballo Patricia Wong EML 4551 Ethics and Design Project Organization FIU Department of Mechanical Engineering Miami, Florida Introduction to Nanoindenters ● Nanoindenter: Materials characterization tool ● Materials testing ● Single compressive force onto a material sample ● Nanomaterials o Nanowires o Biomaterials TI-900 Nanoindenter Problem Statement ● Convert vertical compressive force to tensile force ● Nanoindenters test the hardness of a nanomaterial by indenting it with a metal tip. Design “Delta” Design “Epsilon” Prototypes Flexures ● Allow for a Fail Safe Design ● A bearing system that allows motion through bending of its hinge elements. ● Useful Features: ○ Light Weight ○ Low Cost ○ Very Low Friction (W/O Lubrication) ○ Maintenance free operaon Materials ● 3D Printed ● For Testing: PLA ● For Final Design: nylon or other softer plastics ● Base of stage made out of carbon steel Testing ● 1 gram of material to simulate the force of the nanoindentor on the stage ● Compare SolidWorks simulation platform displacement with Nanoindenter testing platform displacement Engineering Standards ● Knoop and Vickers Hardness of Materials -ASTM E384 ● Instrumented Indentation testing -ASTM E2546 ● Defining standards Multi-disciplinary Teamwork Responsibilities / Titles Research Design Proposals Academic Reports and Presentations Solidworks Specialist ( Design analysis) Design Engineer ( Design considerations and global impact ) Manufacturing Engineer ( Prototype construction & testing ) Erick Camacho BS in Mechanical Engineering James Caraballo BS in Mechanical Engineering Patricia Wong BS in Mechanical Engineering Teamwork Environmental and Economical Aspect • Our projects could solve many engineering issues • 3D Printing leaves a small footprint compared to other manufacturing techniques (PLA is Biocompatible) • Applying for a patent • Universal capabilities that influence all industries Global Awareness/Perspective/Engagement ● Ability to perform unique tests, and reproduce it anywere a nanoindenter is available ● Materials Genome ● Materials research is essential to all industries Conclusions and Future Work ● Final design must have linear relationships between applied load and tensile load on material tested. ● Material selection for indenter insert must account for deformation. ● Generic design for use with all nanoindenter models. ● Materials define Ages Nanoindenter force converting stage Team 13 Erick Camacho James Caraballo Patricia Wong EML 4551 Ethics and Design Project Organization FIU Department of Mechanical Engineering Miami, Florida Literature Survey ● Mechanical Engineering and Materials Science Department in Rice University Force on sample = 0.67 × Force applied by indenter Design Brainstorming mechanism - Indentor pushes downwards - Sliders move horizontally, applying tensile force Design Iterations Design Iterations 30 Degrees Design Iterations 45 Degrees Design Iterations 60 Degrees