Dow Corning at Barry

advertisement

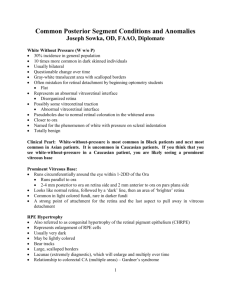

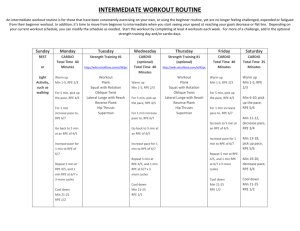

Dow Corning INTERNAL A day in the life of a Dow Corning Industrial Hygienist Dow Corning INTERNAL The Dow Corning Site at Barry, Wales The site was established in 1957 by Midland Silicones. Manufacture of silicone intermediates and final products. Distillation / hydrolysis / compounding processes. Globally 12000 employees with 25000 customers and over 7000 products At Barry we have approximately 600 employees and at times up to 600 extra contract staff. Dow Corning INTERNAL Industrial Hygiene As an Industrial Hygienist my job covers monitoring and controlling exposure to : • Noise • Vibration • Chemicals / vapors / lead etc • Dusts (asbestos / crystalline silica) • Radiation • Ergonomics • Biological Hazards • Temperature • EMF’s Dow Corning INTERNAL Looking at chemical and dust exposures Where there is potential for workers to be exposed to chemical vapors and dusts we use engineering controls wherever possible. Engineering controls include: General Ventilation Local Exhaust Ventilation Vented enclosures Sealed systems Where these cannot be used or are not effective enough we use RPE, as a last of defense for exposure. Dow Corning INTERNAL What do we use? On our site we use the following forms of Respiratory Protection. • Breathing Apparatus • Full face respirators • Half face respirators • P3 dust masks • Air fed hoods • Some nuisance odor masks Dow Corning INTERNAL A Cradle to Grave Approach (or should that be cradle to retirement?) TASK PPE PERSON CONTROL Dow Corning INTERNAL Analysing the task. TASK For new processes : 1) 2) 3) 4) Design out exposures. Decide on engineering controls. COSHH assessments to determine RPE required. Carry out Industrial Hygiene monitoring to determine actual exposures once processes are in place (and re-assess). For existing processes : 1) Carry out Industrial Hygiene monitoring to determine actual exposures. 2) Modify or re-design if possible. 3) COSHH assessments to determine PPE required (if not already being used). Dow Corning INTERNAL Training the person PERSON All job roles aligned to a training matrix which identifies tasks that require RPE, so before they start we know if they will need to use it. Initial medical for potential RPE users includes lung function, blood, and other tests to determine the persons suitability for wearing RPE. The training matrix identifies that RPE wearers should have the RPE training and a full face fit test for each mask before they carry out any tasks. They attend an RPE awareness session (or video) which explains why RPE is used, how to use it and how to check it before use. Dow Corning INTERNAL Issue of the mask RPE Once the person has had the training he attends a Face Fit Test Assuming they meet the criteria (clean shaved etc) they undergo the test which is carried out by the Kit Issue Operative (Steve), or one of the 4 other trained Fit Testers on site. Assuming a PASS a mask is then issued to the operator and facilities made available for storage and cleaning of the mask. (BA wearers do not have their own masks, they book these out along with the trolley packs). Dow Corning INTERNAL Control PERSON CONTROL RPE TASK The trick to any system like this is the element of control. Dow Corning INTERNAL Task Control PERSON CONTROL RPE TASK 1) COSHH Assessments reviewed every 2 years or on change of process (of chemicals). 2) Periodic IH monitoring using a QEA program to identify potential issues. 3) HONK system for immediate reporting of problems with processes. 4) Continual improvement program looking at new technologies and techniques to reduce exposures Dow Corning INTERNAL Person Control 1) PERSON 2) CONTROL 3) RPE 4) TASK 5) 6) Annual Medical with lung function / blood tests etc to identify any problems early. Annual repeat Face Fits for all RPE that requires it. RPE training package redelivered every 2 years as part of an automated training system. Training records available at kit issue point so RPE does not go out to untrained personnel. Management of change system to identify when people change jobs. Exit medical. Contract Staff also have to have Face fits before masks are issued however they are not Covered by the training matrix. Contracts set up to include responsibilities for contract Companies to repeat fit tests / training) Dow Corning INTERNAL RPE Control PERSON 1) 2) CONTROL 3) RPE TASK 4) 5) All RPE issued from one location with access to training / face fit records. RPE issued by staff trained in Fit Testing (to identify issues with facial hair etc. before issue) All RPE electronically tagged and associated to the training record of the wearer. Tagging system recall’s all masks once per year for inspection / repair by Fit to Fit Accredited staff. Single point of contact for all RPE issues (manned 24hrs). Dow Corning INTERNAL The Team Fit Testers Gareth & John Kit Issue Medical Steve Gerry and Chris Tracked RPE Training matrix / medical records Fit test Results Dow Corning INTERNAL What Industrial Hygiene definitely isn’t !!! There’s a pigeon in the tree outside my window that doesn’t look very well, can you come and deal with it? I have just rubbed my eye after eating chilli crisps, what should I do? The drains in our mess room smell funny. Can I have one of those respirators without filters? I find it hard to breath in this one. I find tests very stressful, can I nip out for a smoke before my face fit test? If I comb my beard flat instead, will I still have to shave? My brother passed his fit test and we look alike so I don’t need one.