A Facility Managers Perspective

advertisement

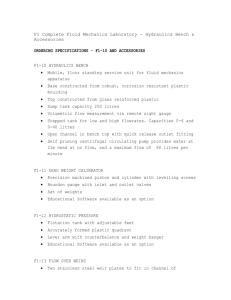

A Facility Manager’s Perspective Jeremy Bowler MIE Aust. MIHE (Ret’d) 1 Content 1. My background 2. Building Owner / Operator’s perspective 3. What effect does construction delivery have on design and who is the real client? 4. The Facility Manager’s expectations 5. The Designer’s role and impact on operations 6. Hydraulics Experiences with copper Experience with PPR 7. A message 2 My Background 17 Years as an engineer in manufacturing (7 as chief engineer) 18 years as Director of Building and Engineering at Barwon Health 2 Years as Manager of Capital Works and Redevelopment at Barwon Health Last 3 years working on Asset Management plans and operational component of bids for Royal Adelaide Hospital and Victorian Comprehensive Cancer Centre 3 Building Owner / Operator Want a facility which: Is functional and fit for purpose Has full availability during operating hours Minimal interruption to operations Lowest overall cost – balance between capital and operating Maximises ROI No surprises 4 Project Delivery and its Effect on Design Traditional Design then tender Design then construction manage D&C Managing Contractor Partial design then assignment of consultants to construction contractor Hard FM may be tendered and managed PPP FM part of bid price Who is the real client? 5 Facility Manager Facility Managers want to be able to sleep at night and to be able to work to a plan Facility ideally designed for: Maintainability Availability Accessibility Sustainability Flexibility This is particularly so for basic infrastructure Facility Managers often not technically qualified Commissioning, Training and Documentation PPP Operational specs require corresponding performance with penalties for failure to meet standards of availability and condition Approximately 80% FM costs and risk largely fixed by the end of design 6 Designer’s Role Easiest conforming solution - low risk high return – Ouch! Responsibility to achieve the best overall outcome Consider WoL and replacement strategy Capital cost Energy Preventative and Reactive Maintenance Life Cycle Replacement Finance cost Operator costs (Soft FM and Hospital) Consider total system Communicate limitations of design Advise clients of options and risks Current PPP documents looking for warranties of up to 40 years, plus designs which are innovative, flexible, durable and unlikely to fail. 7 Hydraulics Until late 90’s, steel and copper Copper seen as long life and trouble free My own experience is that, in potable water systems, it is not trouble free 1997 Geelong Hospital: Leaks in straight lengths of DHW pipe Leaks on bends DHW and condensate Blue water DCW Leaks in DHW in other buildings 1998 paper delivered at IFHE conference identifying widespread problems in Scotland Literature search identified further events – I was not alone! 8 Hydraulics 1999 Survey through IHEA sought incidence of pin holes, blue water and electrical influence Response from 94 hospitals 68% reported corrosion problems 54% had experienced pin hole corrosion, 13 of 15 hospitals in WA 35% experienced blue water Melbourne and Sydney metro reported few incidences Regional areas significantly affected 2001 SBSE Seminar 9 Hydraulics Our response was to use PPR pipe for potable water from 1999 Utilised in McKellar Centre redevelopment 400+ Aged care, palliative and rehabilitation, first building completed 2003. Warm water systems tested for Legionella monthly Review in 2012 indicated no problems reported Asset review of Northern Hospital revealed failure in PPR pipe installed in 1997. Review indicates due to installation utilising incorrect clipping and reported prolonged elevated temperatures 10 Pipework Considerations Total system Velocity to achieve function Effect of velocity on system components Correct material for application Heat source and temperature control Redundancy and system size Control in construction to ensure design is delivered How embedded is main reticulation? Service variability and sensitivity to life cycle changes Commissioning plan 11 A Message Key infrastructure needs to be either resilient or have a workable replacement strategy Hydraulic systems are fundamental to operations in hospitals, prisons and hotels The consequences of poor design and selection decisions are usually born by someone else Leaks cause significant damage and downtime Leaks cause infections (Aspergillus etc.) Systems need to be considered wholistically Risks and limitations of any design should be understood and communicated Standard practice should be regularly reviewed to ensure it is Good practice 12