Shape memory alloys

advertisement

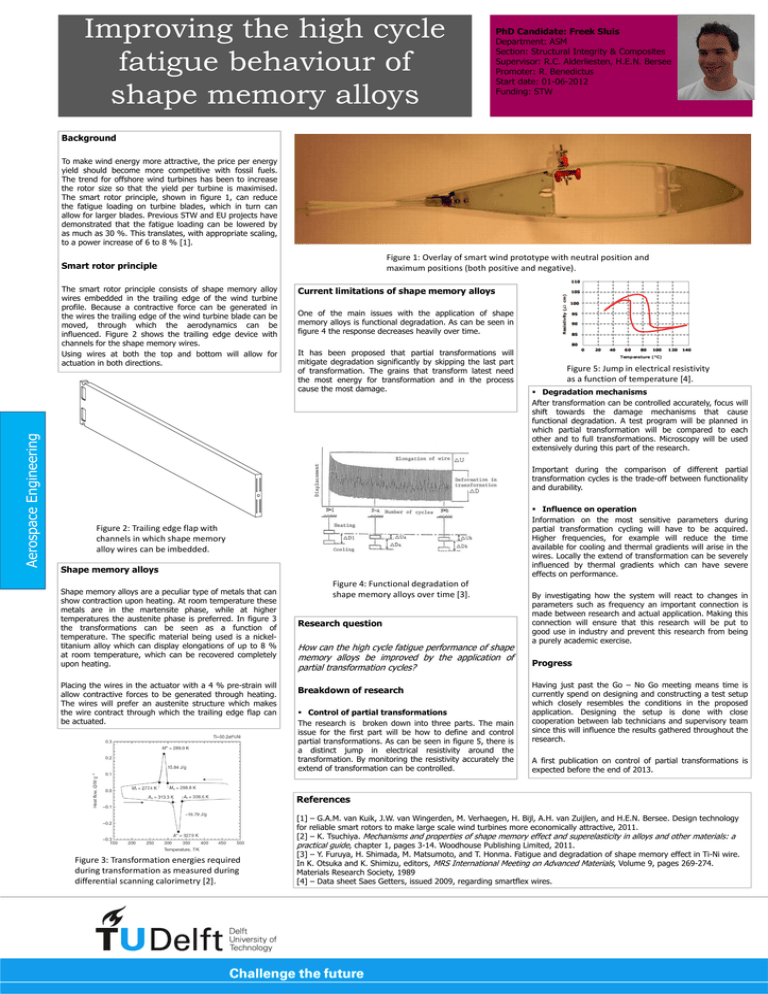

Improving the high cycle fatigue behaviour of shape memory alloys PhD Candidate: Freek Sluis Department: ASM Section: Structural Integrity & Composites Supervisor: R.C. Alderliesten, H.E.N. Bersee Promoter: R. Benedictus Start date: 01-06-2012 Funding: STW Background To make wind energy more attractive, the price per energy yield should become more competitive with fossil fuels. The trend for offshore wind turbines has been to increase the rotor size so that the yield per turbine is maximised. The smart rotor principle, shown in figure 1, can reduce the fatigue loading on turbine blades, which in turn can allow for larger blades. Previous STW and EU projects have demonstrated that the fatigue loading can be lowered by as much as 30 %. This translates, with appropriate scaling, to a power increase of 6 to 8 % [1]. Figure 1: Overlay of smart wind prototype with neutral position and maximum positions (both positive and negative). Smart rotor principle Aerospace Engineering The smart rotor principle consists of shape memory alloy wires embedded in the trailing edge of the wind turbine profile. Because a contractive force can be generated in the wires the trailing edge of the wind turbine blade can be moved, through which the aerodynamics can be influenced. Figure 2 shows the trailing edge device with channels for the shape memory wires. Using wires at both the top and bottom will allow for actuation in both directions. Current limitations of shape memory alloys One of the main issues with the application of shape memory alloys is functional degradation. As can be seen in figure 4 the response decreases heavily over time. It has been proposed that partial transformations will mitigate degradation significantly by skipping the last part of transformation. The grains that transform latest need the most energy for transformation and in the process cause the most damage. Figure 5: Jump in electrical resistivity as a function of temperature [4]. Degradation mechanisms After transformation can be controlled accurately, focus will shift towards the damage mechanisms that cause functional degradation. A test program will be planned in which partial transformation will be compared to each other and to full transformations. Microscopy will be used extensively during this part of the research. Important during the comparison of different partial transformation cycles is the trade-off between functionality and durability. Influence on operation Information on the most sensitive parameters during partial transformation cycling will have to be acquired. Higher frequencies, for example will reduce the time available for cooling and thermal gradients will arise in the wires. Locally the extend of transformation can be severely influenced by thermal gradients which can have severe effects on performance. Figure 2: Trailing edge flap with channels in which shape memory alloy wires can be imbedded. Shape memory alloys Shape memory alloys are a peculiar type of metals that can show contraction upon heating. At room temperature these metals are in the martensite phase, while at higher temperatures the austenite phase is preferred. In figure 3 the transformations can be seen as a function of temperature. The specific material being used is a nickeltitanium alloy which can display elongations of up to 8 % at room temperature, which can be recovered completely upon heating. Placing the wires in the actuator with a 4 % pre-strain will allow contractive forces to be generated through heating. The wires will prefer an austenite structure which makes the wire contract through which the trailing edge flap can be actuated. Figure 4: Functional degradation of shape memory alloys over time [3]. Research question How can the high cycle fatigue performance of shape memory alloys be improved by the application of partial transformation cycles? Breakdown of research Control of partial transformations The research is broken down into three parts. The main issue for the first part will be how to define and control partial transformations. As can be seen in figure 5, there is a distinct jump in electrical resistivity around the transformation. By monitoring the resistivity accurately the extend of transformation can be controlled. By investigating how the system will react to changes in parameters such as frequency an important connection is made between research and actual application. Making this connection will ensure that this research will be put to good use in industry and prevent this research from being a purely academic exercise. Progress Having just past the Go – No Go meeting means time is currently spend on designing and constructing a test setup which closely resembles the conditions in the proposed application. Designing the setup is done with close cooperation between lab technicians and supervisory team since this will influence the results gathered throughout the research. A first publication on control of partial transformations is expected before the end of 2013. References Figure 3: Transformation energies required during transformation as measured during differential scanning calorimetry [2]. [1] – G.A.M. van Kuik, J.W. van Wingerden, M. Verhaegen, H. Bijl, A.H. van Zuijlen, and H.E.N. Bersee. Design technology for reliable smart rotors to make large scale wind turbines more economically attractive, 2011. [2] – K. Tsuchiya. Mechanisms and properties of shape memory effect and superelasticity in alloys and other materials: a practical guide, chapter 1, pages 3-14. Woodhouse Publishing Limited, 2011. [3] – Y. Furuya, H. Shimada, M. Matsumoto, and T. Honma. Fatigue and degradation of shape memory effect in Ti-Ni wire. In K. Otsuka and K. Shimizu, editors, MRS International Meeting on Advanced Materials, Volume 9, pages 269-274. Materials Research Society, 1989 [4] – Data sheet Saes Getters, issued 2009, regarding smartflex wires.