Quality Management System Certification

International Aerospace Quality Group (IAQG)

Other Party Management Team (OPMT)

Prepared by:

Tim Lee

– Chair IAQG OPMT

The Boeing Company

October 10, 2013

Quality Management System

Certification

Montreal - Conference

Purpose & Topics

Purpose:

•

To provide an overview of the Industry Controlled Other Party (ICOP)

AS9100/9110/9120 Quality Management System (QMS) certification oversight processes

•

Describe how organizations can prepare for an audit and the value of

ICOP certification

2

Agenda Topics:

•

9100 Series Standards & Document Relationship

•

What is ICOP

•

Other Party Management Team (OPMT)

•

Audit Preparation and ICOP Value

•

Summary

•

Q & A

3

9100 Series of Standards

Quality Management Systems

•

EN/AS/JISQ 9100 - Requirements for Aviation, Space and Defense

Organizations

•

Organizations that design, develop and/or produce aviation, space and defense products; and by organizations providing post-delivery support.

•

EN/AS/SJAC 9120 - Requirements for Aviation, Space and Defense

Distributors

•

Organizations that procure parts, materials and assemblies and resell these products to a customer in the aviation, space and defense industries.

•

EN/SJ9110 - Requirements for Aviation Maintenance Organizations

•

Organizations whose primary business is providing maintenance, repair and overhaul services for aviation commercial and military products; and original equipment manufacturers.

IAQG Document Relationship

IAQG OWNERS DATA

Oversight of Certification Scheme

9104-1

(organization) 9104-2

(surveillance/certs)

9104-3 (auditors)

9100

(General)

Quality Management System

Requirements

Standards /

Technical

Reports

9102

FAI

9103

Key Char.

9110

(Maintenance)

9120 (Distributors)

9115

Software

9107

DDA

9114

Direct ship

9137

AQAP align.

9131

N/C Doc

9162

Operator Self Verif

9132

Marking

9133

Sup.Qual.

9101

Audit

Process

9134

Sup risk

Supply Chain Management Handbook (SCMH)

1

Sales &

Scheduling

2 3

Requirement

Flow down

Design &

Developm’t

4

Sourcing selection

5

Plant, skills & planning

6

Order Mgt

& logistics

7

Manufact.

&

Inspection

8

Supplier

Mgt.

9

Control of

N/C mat’l

C/A & P/A

10 11

Customer

Support

Business

Processes

Data Type

People Capability documents

(PCAP001)

& structure

(skills matrix)

4

5

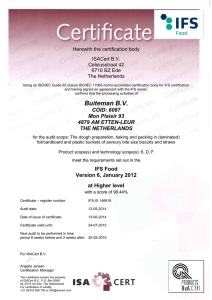

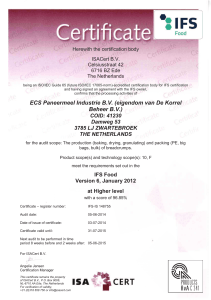

WHAT IS ICOP?

•

ICOP is a globally harmonized 9100/9110/9120 Aerospace

Quality Management System (AQMS) Certification process defined by the IAQG

•

Industry Controlled:

•

The IAQG through each Sector provides direct oversight of all AQMS certification activities

•

Other Party:

•

Certifications activities are conducted by accredited

Certification Bodies (CB) and Authenticated Aerospace

Experienced Auditors (AEA) that are recognized through the ICOP process

•

ICOP process is managed by the IAQG Other Party

Management Team (OPMT)

6

Industry Controlled Other Party

• Our Aviation, Space & Defense sector certification scheme utilizes ISO for basic requirements and supplements ISO with

Aviation, Space and Defense (AS&D) unique requirements.

• ISO 9001 as supplemented by 9100

• Certification Criteria is Linked to ISO 17021 and

IAF Documents

IAQG OPMT

•

Mission:

•

Management and oversight of the 9100 series

Aviation, Space and Defence Quality

Management System certification program.

•

Vision:

•

A measurable IAQG quality management system certification program that is efficient, recognized and brings benefit to all stakeholders

Page 7

Other Party Management Team

OPMT

Other Party Management Team

Committee

IAQG

Council

8

RMC

(Americas)

Sector Management Structures

Voting Members;

ABs;

CBs; and

Industry

Representatives

OPMT

(Europe)

Voting Members;

ABs;

CBs; and

Industry

Representatives

JRMC

(Asia / Pacific)

Voting Members;

ABs;

CBs; and

Industry

Representatives

•

Acronyms

RMC - Registration

Management Committee

OPMT - Other Party

Management Team

JRMC - Japan Registration

Management Committee

AB - Accreditation Bodies

CB - Certification Bodes

ICOP Criteria

•

9104-001 – Accreditation/Certification Requirements

•

Certification Structures

•

Sector Requirements

•

Recognized Accreditation Bodies (ABs)

•

Accredited Certification Bodies (CBs)

•

Authenticated Aerospace Auditors

•

Auditor Authentication Bodies (AABs)

•

OASIS database management

•

9104-002- Oversight

•

Oversight and surveillance process to ensure conformance to established aerospace industry 9100-series standard accreditation/certification requirements

•

9104-003 – Auditor Authentication & Training

•

A common process for aerospace auditor training and authentication to be utilized by all the IAQG sectors

Certification Structures

•

Prior to 9100 Series ICOP certification an organization must work with their contracted CB to determine the appropriate

AS9104/1 (Appendix B) defined certification structure that supports their internal organization structure.

•

Certification Structure options include:

•

Single Site - Organization having one location

•

Multiple Site – QMS with multiple locations, similar processes

•

Several Site – Single QMS with several independent sites

•

Campus – Single QMS with sites that support same Value Stream

•

Complex – Single QMS with combination of the above structures

•

A defined structure will assist CBs with the development of a robust and conforming audit program, and provide industry with visibility of the structure within the OASIS database.

On-Line Aerospace Supplier

Information System (OASIS)

•

•

•

OASIS Database – 15,000 Sites

Database where all information related to ICOP certifications, auditors and audit results is stored

Only general information such as Accreditation Bodies, Certification

Bodies, Certified Supplier sites, Approved Auditors is publicly accessible.

•

•

Includes a list of approved Certification Bodies (CB)

Includes a robust Stakeholder Feedback process to Industry

Leaders, Certification Bodies and Document Reps

OASIS LINK

Page 11

Audit Prep

12

•

Preparation

•

Top Management Commitment

•

Obtain Industry Standards: 9100/9110/9120 QMS; 9104-001

Accreditation/Certification; 9101 Assessment Process;

•

Update procedures and processes

•

Incorporate Customer and Regulatory requirements

•

Ensure all personnel have been adequately trained

• Implement “Process Approach”

•

Processes identified, interrelationships and linkages defined

•

Performance measures & objectives established, supported with metrics

•

Actions taken when objectives are not met

•

Complete an internal audit to verify conformance

•

Address identified non-conformances via robust corrective action process.

Audit Prep & CB Selection

13

•

Preparation (continued)

•

Conduct Management Review to analyze health of QMS and address resources needed to maintain and improve QMS

•

Focus on Customer expectations and address customer complaint

•

Personal accountability

•

Certification Body (CB) Selection

•

Contract with an ICOP approved Certification Body (CB) that is listed in OASIS

•

Service Provider

•

Competitive Bid Process

•

Set high expectations (Add Value)

•

Work with CB to prepare for and complete certification process

•

Certification Structure Determination

•

Stage 1 Audit Prep & Stage 2 Audit

•

Corrective Action & Certification Decision

ICOP Benefits

14

•

Value of ICOP

•

Globally harmonized certification scheme that is recognized by major

Aviation, Space and Defense companies

•

Supports supplier approval activities with a recognized quality management system certification

•

Public database (OASIS) listing all certified organization and their status

•

Process approach to conformance assessment

•

Analysis of effectiveness

•

Focus on exceeding customer expectations

•

Supports Customer supplier approval processes

•

Reduces redundant QMS Audits

Resources

IAQG Website

AAQG Website

Excellent starting points for resources.

Page 15

Resources

AS9104/1 Link

AS9100C Link

AS9101D Link

Page 16

Resources

• 9100 Deployment Page – Numerous Resources

Link: http://www.sae.org/iaqg/organization/requirements.htm

Page 17

Supply Chain Management Handbook (SCMH)

• The SCMH provides guidance material to help continuously improve On Time,

On Quality Delivery

(OTOQD)

• It is provided at no cost and is available to all levels of the supply chain

• Link: http://www.sae.org/scmh/

18

Summary

19

•

Industry Controlled Other Party

•

Globally harmonized – Stakeholder Accountability

•

Audit Preparation

•

Ensure adequate audit duration has been agreed to with the CB

•

9104-001 provides minimum duration only

•

Conduct an effective internal audit to verify conformance

•

Process metrics on the shop floor not in the board room

•

ICOP Value

•

Independent assessment of conformance

•

Validates investment in Quality Management System

•

Globally recognized certification process

•

Process focused audits

•

Use effectiveness evaluation to identify opportunities for improvement

•

Working Together to continually improve the Aviation, Space and

Defense AS9100/9110/9120 certification process

Questions…..

ICOP Certification Scheme: Efficient - Recognized - Beneficial

Page 20