ATR112_-_Week_1

advertisement

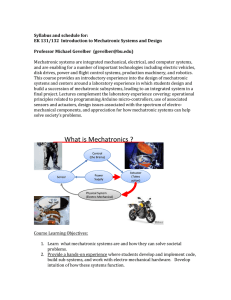

Jami Dale Mechatronics Instructor ATC302A Jami.dale@cpcc.edu x6545 jami.dale.people.cpcc.edu Moodle Syllabus Attendance! *Semester of Program? *Your goals for course? *Internet/PC access? Software Skills? *Industry Experience? *Exposure to Automation? Automation (aka Mechatronics) History Principles Components Safety Analysis Tools Troubleshooting Simulation & Hands On Mechatronics vs. Automation & the interchangeability Mechatronics is a principle of operation Mechatronics History Principles Siemens Certified Mechatronic Systems Assistant Operator • Understand & explain the principal operations of the mechatronic subsystems & how they work together. • Localize malfunctions, identify causes & sources of malfunctions, correct malfunctions where possible. • document malfunctions to pass to experts for resolution to keep production functioning preventing loss. • Read & understand the technical documents, reports & outlines specific to the system. • Perform routine & preventive maintenance. • Understand & implement safety regulations required for operation of the system. Siemens Certified Mechatronic Systems Associate Line Technician • Understanding & analyzing the technical specification of mechatronic systems, modules and components. • Deriving & determining parameters for mechatronic systems & system elements. • Measuring, interpreting & analyzing electrical, PLC/microcontroller & mechanical values. • Assembling and installing tools and hardware systems. • Using troubleshooting skills to identify, foresee & prevent possible problems, conflicts & failures & to systematically & intelligently make repairs. • Programming mechatronic modules & systems. • Observe, follow, and influence cost control & process efficiency procedures. Automation (aka Mechatronics) is a design philosophy Siemens Certified Mechatronic Systems Associate Process Tech • Define the functional requirements of a mechatronic system with ‘use cases’, interviews with customers & users, & systems modeling techniques. • Perform high-level design by defining appropriate mechatronic systems to perform specific tasks; Utilizing knowledge of machine elements, actuators, pneumatics & electric drives. Traditional ‘bottom up’ System Approach ‘top down’ Internet!! ‘Best Practices’ Books & Papers Handouts Festo MPS 500-FMS Overview of operation • what is being made • system startup • stations operations