Pick-Face Area

advertisement

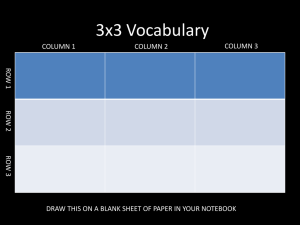

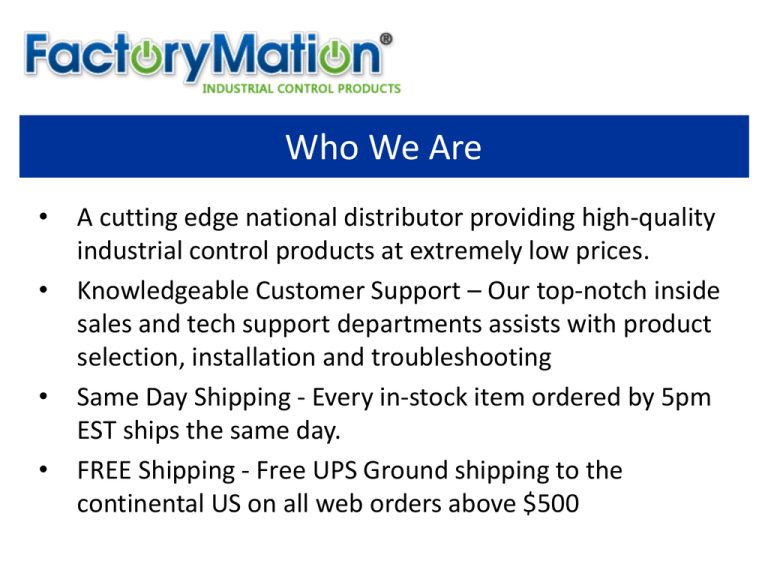

Who We Are • • • • A cutting edge national distributor providing high-quality industrial control products at extremely low prices. Knowledgeable Customer Support – Our top-notch inside sales and tech support departments assists with product selection, installation and troubleshooting Same Day Shipping - Every in-stock item ordered by 5pm EST ships the same day. FREE Shipping - Free UPS Ground shipping to the continental US on all web orders above $500 Who Are Our Customers? • Any industry that has some type of manufacturing process is a potential customer. Industries such as Automotive, Food and Beverage, Packaging, Waste Water, Pharmaceutical, Oil and Gas are just a few examples where you will find a high degree of automated assembly or process taking place. • Diverse group of customers range from Fortune 100 companies to retirees who have taken up woodworking in their garage. Importance of Warehouse • Due to the nature of our business, it is imperative we ship orders quickly and accurately. • Many purchases are to replace products that have expired, causing costly shutdowns for our customers. Considerations • FactoryMation is a young, rapidly growing organization. Our goal is to dramatically improve efficiency in order to double our output without adding additional headcount. • The bulk of our orders are labor intense piece picks. • FM is flexible. We will consider any and all ideas to help improve efficiency and increase accuracy. • FM plans to open additional warehouses in the coming years. We plan to use the layout of this facility as a guide to future warehouse design. • Some items have significant lead-times and they are shipped immediately upon arrival. Need to determine the best way to quickly move these from item receipt to order fulfillment. Old system Warehouse Cheat Sheet Row 1: Brook Crompton Motors Row 2: Teco & Allied Row 3: Iboco Row 4: Teco Row 5: LS/Metasol Row 6: LS/Metasol Row 7: Weg & J. Auer Row 8: Micron, Aeco, & Delta Row 9: Magnecraft, Repol, Elko, Ferraz, & Misc. Row 10: Bimed, & Chint Row 11: Autonics, Menics, Finder, & Kitel Row 12: IMO, Greenlee, & Teco Row 13: Eldon Row 14: Eldon Row 15: Eldon Row 16: Hibox & Scame Row 17: Saginaw Row 18: Saginaw Row 19: Eldon Enclosures Row 20: Eldon Enclosures Back Wall: Ferraz Fuses • Pickers required to memorize location of products based on manufacturer. • Items sorted alphabetically • New employees struggled to find products. Took months to get familiarized with locations • No weight or dimensions taken into consideration New system Bin Locations • First two digits represent Aisle/Row • Second set of numerical digits represent Bay/Pallet Position • Third character (letter) signifies Shelf Position/Pallet level • Fourth set of characters (numeric) indicates bin Pick-Face Area G F E D C B A 01-01-C-02 • Areas below shaded in green represent fixed bin locations, except for top shelf • Top shelf of green area is overflow along with areas below shaded in blue. • Unshaded areas indicate rack-pick, Pallet Storage or unit-load areas. Inbound Warehouse Processes: Receiving/Putaway Warehouse Processes: Receiving/Putaway Warehouse Processes: Receiving/Putaway Handheld Mobile Computer Utilized • Receiving – Each item is scanned to ensure accuracy. • Putaway – Handheld mobile device directs warehouse personnel through warehouse in most efficient manner to complete putaway process. Warehouse Processes: Receiving/Putaway Outbound Warehouse Processes: Picking & Fulfillment Warehouse Processes - Outbound • Picking – Each bin location is scanned to ensure accuracy. Like putaway, the mobile computer will guide the picker through the warehouse using the most efficient route. • We will be batch picking. Multiple orders are grouped into small batches to reduce travel. • At the time of fulfillment, individual items will be scanned to ensure accuracy and verify quantities. Warehouse Processes: Fulfillment/Shipping Small Parcel Shipping Dock Challenges • What is the best way to determine product placement in bins? • Should FM arrange SKUs by Product Family and Groups? This would simplify putaway and replenishment, but would not be as efficient when picking. • Should FM arrange SKUs solely by sales volume? Much more efficient for picking, but more difficult to replen and putaway. • What is the best way to layout the pick-face area to maximize efficiency? • What size bin is best for each SKU? • How much product should FM keep in each bin based on prior sales history? • How often should FM replenish? • How to determine reorder points and safety stock for bins? • Determine optimal shipping carton size to reduce cost and void fill required. • Where should shipping and receiving docks be located? • What is the best method for measuring performance? Questions