A Slow Pyrolysis Reactor Utilizing Concentrated Solar Radiation to

advertisement

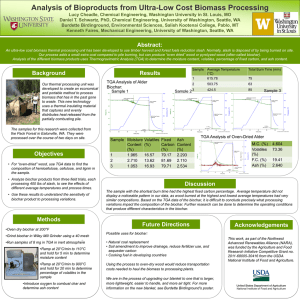

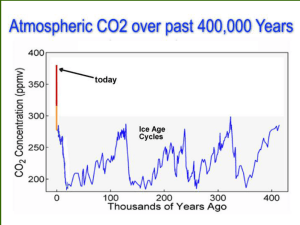

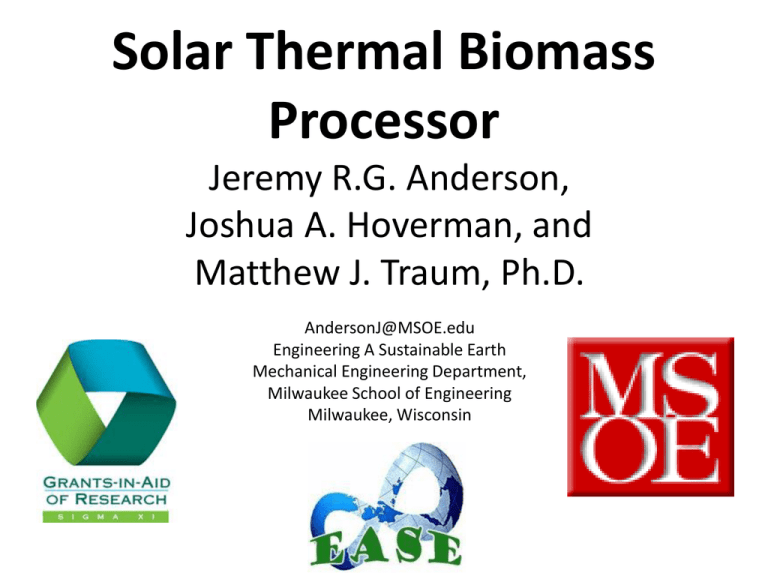

Solar Thermal Biomass Processor Jeremy R.G. Anderson, Joshua A. Hoverman, and Matthew J. Traum, Ph.D. AndersonJ@MSOE.edu Engineering A Sustainable Earth Mechanical Engineering Department, Milwaukee School of Engineering Milwaukee, Wisconsin Overview • Thermal Processing • Markets • Benefits • Progress • Future Work • Desired Outcomes Parabolic Trough Receiver Tube (Reactor) Hopper Controls Products Parabolic Trough Waste Biomass In Drying electricity Torrefaction Pyrolysis Syngas Biochar 300K – 373K 473K – 553K 553K – 873K 800F – 2100F 3900F – 5350F 5350F – 1,1110F fertilizer System Parameters Q mc T Heat P Q t mc T t Power P=16kJ/s=16kW 16m2 Needed At 15 MJ/kg Energy cycle per hour Heat Loss 8 MJ 900 MJ Solar Receiver Tube(Reactor) 58 MJ 617 MJ Syngas Heat Biochar 333 MJ Markets • Agriculture • Forestry • Municipal waste • Bio-fuel production Environment • Renewable energy • Carbon sequestering process • Facilitates organic farming • Improves soil quality • Reduces run-off pollution Economics • Energy products • Eliminate solid-waste tipping fees • Reduce fertilizer costs (Biochar) • Carbon credit sales • Creates new sustainable jobs • Retains current jobs Biomass Syngas Biochar Prototype Components Phase II • FF-MCHP system (Flexible Fuel Micro Combined Heat and Power) • Consolidate power generation with hot water and air services • Develop a robust and inexpensive disc turbine for power generation • Design intuitive turbine controls for optimal waste heat utilization • Optimize total system thermal efficiency Syngas Methane Modified Brayton Cycle Combustion Chamber Disc Turbine Comp ATM Hot Water Gen. Hot Air ATM Disk Turbine Components Nozzle Rotor Source: Budapest University of Technology and Economics, Ferenc Lezsovits Desired Outcomes • Pilot system for Sweet Water by May 2013 • Closed loop urban agriculture • Synergy of multiple technologies • Proof of concept Solar Thermal Biomass Processor Jeremy R.G. Anderson, Joshua A. Hoverman, and Matthew J. Traum, Ph.D. AndersonJ@MSOE.edu Engineering A Sustainable Earth Mechanical Engineering Department, Milwaukee School of Engineering Milwaukee, Wisconsin Acknowledgements • EASE Board of Directors • Sigma XI • MSOE Research Team –Josh Hoverman –Kyle Pace –Matt Wesley References [1] Steinfeld A, Palumbo R: Solar Thermochemical Process Technology. In: Meyers RA, editor. Encyclopedia of physical science and technology. New York: Academic Press, ISBN 0-12227410-5, 2001;15:237–56. [2] Carolan J, Joshi S, Dale B: Technical and Financial Feasibility Analysis of Distributed Bioprocessing Using Regional Biomass Pre-Processing Centers. J Agric Food Ind Org 2007, 5:129. [3] Gallagher P, Dikeman M, Fritz J, Wailes E, Gauther W, and Shapouri H: Biomass from Crop Residues: Cost and Supply Estimates. U.S. Department of Agriculture, Office of the Chief Economist, Office of Energy Policy and New Uses. Agricultural Economic Report No. 819 [4] Kellig R, Brenta G, Stephen J, Norman R, Nelsehmann S: Biochar for Environmental Management: Science and Technology. College of Agriculture and Life Sciences, Cornell University, Ithaca, New York 14853, and School of Materials Science and Engineering, University of New South Wales, Sydney, NSW2251, Australia [5] Prins M, Ptasinski K, Janssen F: Thermodynamics of Gas-Char Reactions: First and Second Law Analysis. Chemical Engineering Science 58 (13-16):1003-1011. [6] Roberts K, Gloy B, Joseph S, Scott N, Lehmann J: Life Cycle Assessment of Biochar Systems: Estimating the Energetic. Economic and Climate Change Potential, Environmental Science and Technology 44, 827–833.