Presentation2

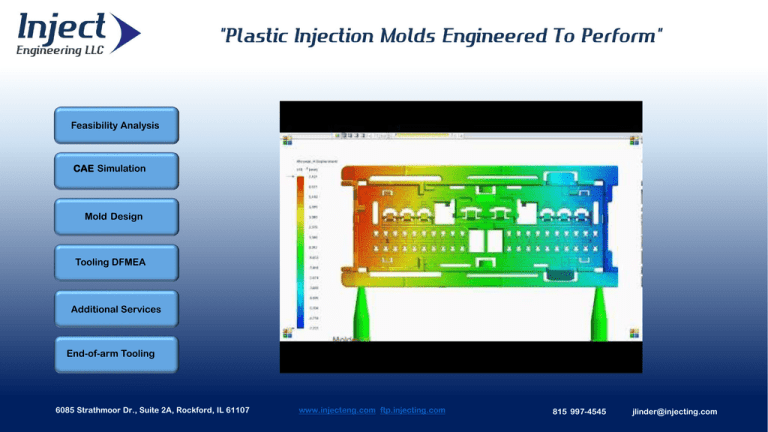

advertisement

Feasibility Analysis CAE Simulation Mold Design Tooling DFMEA Additional Services End-of-arm Tooling 6085 Strathmoor Dr., Suite 2A, Rockford, IL 61107 www.injecteng.com ftp.injecting.com 815 997-4545 jlinder@injecting.com Manufacturing Feasibility Analysis Every new project begins with a manufacturing feasibility analysis. The part model is examined to ensure the part has sufficient amounts of draft so the part will release properly from the mold. Part features which could cause premature steel failure are identified and communicated to the client. Undesirable cosmetic issues are reviewed. 2D drawings and 3D model files are compared for compatibility. Modifications to the part model needed for manufacturability are reviewed and included in the quotation. All potential product design improvements are discussed with the client prior to starting the project. 6085 Strathmoor Dr., Suite 2A, Rockford, IL 61107 www.injecteng.com ftp.injecting.com 815 997-4545 jlinder@injecting.com CAE Mold Simulation • • • • • • • • 6085 Strathmoor Dr., Suite 2A, Rockford, IL 61107 Gate location and runner size is determine for best filling and packing pattern Uniform and balanced cooling schematic is developed for turbulent flow characteristics Knit lines, flow lines, sink mark are identified Air trap analysis show areas needing venting Shrinkage values are defined Warpage potential is compared to 2D drawing specifications and requirements Initial processing parameters are charted What-if simulations are used to optimize the process and part geometry www.injecteng.com ftp.injecting.com 815 997-4545 jlinder@injecting.com Mold Design • • • • • • • • • Molds Designed in NX (UG) 3D Solid Model Designs 2D Drawings available as required Mold Components based on USA Sources Designs Based on SPI/SPE Class 101 Standards Preliminary Designs in 3 Days Final Designs in 7-10 Days Multiple Mold Design Packages in Same Time Stack-up Analysis between mating Components 6085 Strathmoor Dr., Suite 2A, Rockford, IL 61107 www.injecteng.com ftp.injecting.com 815 997-4545 jlinder@injecting.com Tooling DFMEA • Technical tool design review process is based on a tooling DFMEA. Every potential failure mode is identified and designed out. • Process begins with the mold ready to load into the press and ends with good part in the box. • Process considers press and process compatibility, mold integrity and reliability items, as well as all major mold systems and components. 6085 Strathmoor Dr., Suite 2A, Rockford, IL 61107 www.injecteng.com ftp.injecting.com 815 997-4545 jlinder@injecting.com Services • Product Design for Manufacturability assistance • Stack-up analysis for mating components • Comparing 2D drawings to 3D model file reviewed to ensure model features are at mid-point of print tolerance zone • Mold building through subcontractors (Domestic & International • Plastic molding (sub-contractors) • Project Management assistance 6085 Strathmoor Dr., Suite 2A, Rockford, IL 61107 www.injecteng.com ftp.injecting.com 815 997-4545 jlinder@injecting.com EOAT (End-of-arm Tooling) • EOAT based on tool design • Plastic fixture plates that are both conformal to part and breakable in crash situations • Plastic fixture plates are about 1/3 the weight of aluminum • EOAT finished when mold is T0 sampling 6085 Strathmoor Dr., Suite 2A, Rockford, IL 61107 www.injecteng.com ftp.injecting.com 815 997-4545 jlinder@injecting.com