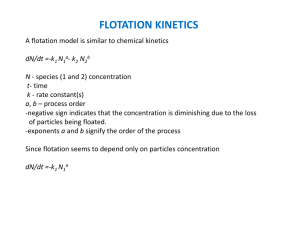

FLOTATION - WordPress.com

advertisement

FLOTATION INTRODUCTION Flotation is an operation that removes not only oil and grease but also suspended solids from wastewaters. The waste flow or a portion of clarified effluent is pressurized in the presence of sufficient air to approach saturation. Waste flow is pressurized to approach saturation released to the atmospheric pressure Minute air bubbles are released from the solution SS, oil & grease, sludge flocs are floated attachment with air bubbles Enmeshed in the floc particles Air-solids mixture rises to the surface AIR SOLUBILITY AND RELEASE The saturation of air in water is directly proportional to pressure and inversely proportional to temperature. The quantity of air that will theoretically be released from solution when the pressure is reduced to 1 atm: AIR SOLUBILITY AND RELEASE AIR SOLUBILITY AND RELEASE The actual quantity of air released will depend (i) upon the turbulent mixing conditions at the point pressure reduction (ii) on the degree of saturation obtained in the pressurizing system AIR SOLUBILITY AND RELEASE Since the solubility in industrial wastes may be less than that in water, a correction have to be applied : FLOTATION UNIT The performance of a flotation system depends upon having sufficient air bubbles present to float substantially all of the suspended solids . An insufficient quantity of air will result in only partial flotation of the solids, and excesive air will yield no improvement. FLOTATION UNIT The performance of a flotation unit terms of effluent quality and solids concentration in the float can be related to an air/solids ratio: FLOTATION UNIT FLOTATION UNIT When pressurized recycle is used: DAF The most common procedure is that of dissolved air flotation (DAF), in which the waste stream is first pressurized with air in a closed tank. After passing through a pressure-reduction valve, the wastewater enters the flotation tank where, due to the sudden reduction in pressure, minute air bubbles in the order of 50- 100 microns in diameter are formed. DAF As the bubbles rise to the surface, the suspended solids and oil or grease particles adhere to them and are carried upwards. It is common practice to use chemicals to enhance flotation performance. One alternate design involves the recycling of part (10-30%) of the treated water. DAF All systems contain a mechanism for removing the solids that may settle to the bottom of the flotation tanks, usually by a helical conveyor placed in the conical bottom. The main advantage claimed of DAF systems is the faster rate at which very small or light suspended solids can be removed in comparison with settling. DAF Performance of DAF systems has been reported to be dependent on several factors: the solids concentration the ratio of air to solids (A/S) Key factors in the successful operation of DAF units are the maintenance of proper pH proper flow rates the continuous presence of trained operators DAF DAF Diagram of a DAF system with recycle DAF DAF DAF SURFACE AERATOR Another flotation system exists in which air is not dissolved but forced through the wastewater by surface aerators. This system generates air bubbles of larger size than DAF systems.