Lecture 5

advertisement

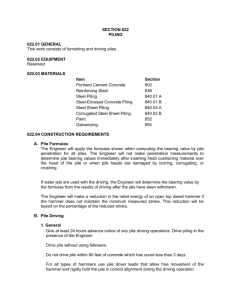

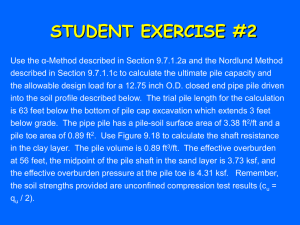

Foundations Excavations ARCH 330 Fall 2008 Yes, I was a stud. The Function of a Foundation Foundations Foundation Engineering- Evaluating the ability to support a given structural load and designing the substructure or transition member needed to support the construction. To transfer the structural loads safely into the ground. This means dealing with forces and soil pressures. The need for deep excavations. Foundations • Spread Footings – Proper compaction under the footing • Driven Piles – Types of piles • • • • Wood Concrete Steel Composite -Pile Drivers • Drop Hammer • Mechanical- Hydraulic, diesel, steam • Vibratory • Caissons or Drilled Shafts • Cofferdams Review Plans & Specifications • Consistency with geotechnical report • Reduce confusion during construction • Without Differing Site Conditions clause contractor responsible • Read the report in response to what is underground. – Understand prescribed method, consistency with soils report • Site Investigations – Environmental restrictions – Site conditions at each and every location • The report has pertinent information- follow it. • Compaction testing – Understanding moisture content – Proper proctor Geotechnical Studies Soils Report • • • • • • Buildings Retaining Walls Bridges Roadways Landslides Forensic Investigations Importance of Geotechnical Studies • • • • Provide efficient foundations systems Improve bid accuracy Reduce change orders Reduce long term problems Geotechnical/Soils Reports Recommendations • • • • • • • Suitability of on site soil for structural fill Bearing capacity Foundation type Lateral earth pressures Pavements Drainage Seismic Steps for Geotechnical Study • • • • • • Explore site conditions Perform lab testing Perform engineering analysis Prepare report Assist with plans and specifications Construction observations Soil Report • Borings or test pits • To lab for: • • • • Moisture content Gradations Proctor test Consolidation, direct shear, triaxial Pile & Pile Driving • Site Investigation – Type & weight of structure – Soil properties – Depth of stratum – Variations of stratum depth – Availability of piling type – Availability of pile driver – Availability of experience in driving pile Pile & Pile Driving (Site Investigation cont) – Comparative placement cost – EPA & OSHA regulations – Depth of excavation for placement of equipment ie building footing – Location of piling ie river, lake, ocean – Noise & Vibration – Adjacent structures Pile & Pile Driving Piling Types Wood Pile Precast Concrete Pile Steel H-Pile Steel Pipe Pile Composite Piles (Please review page 571-594) Pile & Pile Driving • Pile Caps & Grade Beams – Piles are clustered then caped • Number of piles per cap are determined by the load bearing capacity of the soil. • From the cap comes a column or bent. • Piles can be connected by grade beams Pile & Pile Driving Pile Drivers • • • • • Drop Hammers Single/Double-Acting Steam Hydraulic Diesel Hammers Vibratory Pile Drivers Caisson or Cofferdam What’s the difference? • Caisson- Boring or drilling a hole and filling with concrete. • Cofferdam- A temporary boxlike structure used to hold back water or earth while work is being done inside it. EXCAVATION • • • • • • • • • • • HORIZONTAL & VERTICAL LAYOUT BEGIN EXCAVATION SWELL AND SOIL TYPES UNSUITABLE SOIL STRUCTURAL FILL SITE DRAINAGE DEWATERING COMPACTION BACKFILL SAFETY MECHANICAL & ELECTRICAL Excavation Wall Bracing No matter what restraining system is used to stabilize the sides of an excavation, the walls will have to be braced against lateral pressures exerted by the surrounding soil and water. • Shoring for trenches (trench boxes) • Lateral forces surrounding the structure – Slope back – Different shoring systems – Tiebacks (rock and earth) Protection of Excavations Lateral Forces Deep Excavations • Slope Back- Usually 2:1, The angle of repose at which a soil material will stand without moving • Interlocking Sheet Piling • Steel Soldier Piles- H beam with lagging • Concrete Slurry walls-Shotcrete (pneumatically projected at high velocity onto a surface) Other piling terminology Battered pile- A pile driven somewhat at an angle so as to resist horizontal forces. Kelly bar- The equipment on the pile driver that determines the height of the pile to drive. EXCAVATION Terminology In the industry terms can mean different things. Toe- (1) Any protection from the base of a construction or object to give it increased bearing and stability. (2)That portion of sheeting below the excavated material. (3) To drive a nail at an oblique angle. (4) The junction between the base metal and the face of a filled weld. (5) The part of the base of a retaining wall that projects beyond the face away from the retained material. Excavation • Need for Deep Foundations • Removing ground water or dewatering • Amount of material to be removed – Soil swell percentage • For removal and replace • Tons to cubic yards • Protection of Excavation – Sheet Piling – Soldier Piles – Concrete Slurry Walls • Excavation Wall Bracing – Slope back – Shoring – Tiebacks Foundation Sequencing Drive Piling- Excavate> >[Slope protection/shoring system]> Layout Piles>Drive Piles>Cut off piles>Fine grade/Compact>Structural Fill> Backfill to follow foundation system Drilled Piling (concrete)- Excavate> >[Slope protection/shoring system]> Layout Piles>Auger piling>Fabricate Cage>Set reinforcing cage>Pour concrete pile>Fine grade/Compact>Structural Fill> Backfill to follow foundation system Spread Footings-Excavate>[Slope protection/shoring system]>Layout>Fine foundation system grade/Compact>Structural Fill> Backfill to follow EXCAVATION EXCAVATION • TABLE V:2-1. ALLOWABLE SLOPES.Soil typeHeight/Depth ratioSlope angle Stable RockVertical90°Type A¾:153°Type B1:145°Type C1½:134°Type A (shortterm)½:163°(For a maximum excavation depth of 12 ft)