Water Purification PowerPoint

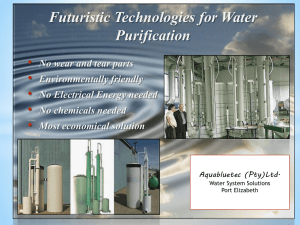

advertisement

WATER PURIFICATION WATER PURIFICATION • We all need clean water, water that is free of potentially dangerous contaminants. • For our homes we need basic clean and sanitary water. Water that can be used for cooking, cleaning and bathing. Water that meets or exceeds the purity standards of our local governments. For bio-pharmaceutical uses, the water used must meet a much higher standard. WATER PURIFICATION • Bio-pharmaceutical manufacturing uses “Water For Injection” (WFI). WFI is considered to be 100% water. This water is free of sediment, minerals, and organic contamination. • WFI is typically contained in stainless steel systems, heated to temperatures just below boiling, and pumped through systems to the point of use that will not allow dead zones where the water does not circulate. WATER PURIFICATION • WFI is used to clean water resistant manufactured medical equipment such as syringes. Under high pressure it is sprayed on this equipment, used to soak it, and injected into the internal parts of the equipment. WATER PURIFICATION • In our homes we might have a sediment filter to remove fairly large particles suspended in the water. Our cars have a sediment filters for oil. Photograph from Wiki Media Commons • Sediment filters for water typically use a cloth or paper filter cartridge. As the water flows through large sediment particles are removed from the water. Sediment removal is frequently the first step in making WFI. WATER PURIFICATION • If the water coming into our homes was to be used to make WFI and has some unwanted biologic residue, chlorine, or a foul odor then a second filter is added. The second filter will be activated charcoal. Activated charcoal will not remove sodium fluoride or nitrates. Photograph from Wiki Media Commons WATER PURIFICATION Typically the two canisters for the filters are connected in simple series. Filter canisters used in our homes are small; a few inches in diameter and less than a foot long. Those used in WFI production for bio-pharmaceutical manufacturing are much larger. Photograph from Wiki Media Commons WATER PURIFICATION • Some locations have water very high in mineral content. These locations will add an ion exchange filter to their series of filters. These beads are made of plastic resin and can be charged to attract specific ions. Photograph from Wiki Media Commons WATER PURIFICATION • A water softener is an ion exchange filter to remove scale producing calcium and magnesium from water. • Water softeners use special resin( small plastic beads) that attract calcium and magnesium ions. • Water softeners cycle periodically to recharge; they flush the residue with salt water to remove (rinse away) unwanted ions. This rinse water is discarded. WATER PURIFICATION • Another device that is added to water purification systems in some homes and in biopharmaceutical manufacturing plants is a reverse osmosis filter. • This device forces water to move against the normal direction of osmosis through a semipermeable membrane. The reverse osmosis requires high pressure to move water through the filter. WATER PURIFICATION • Reverse osmosis removes bacteria, spores and viruses from water. • Water after being run through the reverse osmosis membrane is very, very clean. The water before the membrane will have a built up of unwanted particles and must be cycled (flushed out) periodically. WATER PURIFICATION WATER PURIFICATION • In the production of water for injection for bio-pharmaceutical manufacturing has an additional stage, distillation. • Distillation heats water to its boiling point, creates vapor which passes through a cooling system, and re-condenses back to liquid water. Water after the distillation process is 100% water. WATER PURIFICATION • Water for injection is kept at high temperatures and is used for a very complete cleaning of medical products. Any small amount of remaining manufacturing residue and biological contaminants are completely cleaned from the product. The product is now ready for clean-room packaging and sealing. • Medical products, such as syringes, are sterilized by gamma radiation after packaging.