The VCTIR Presentation in Powerpoint format - Trb

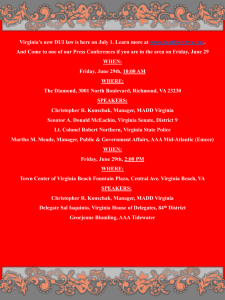

advertisement

SESSION: DEICER MANAGEMENT SOLUTIONS Salt Management Research in Virginia Jimmy White, Virginia Center for Transportation Innovation & Research The Virginia Department of Transportation (VDOT) is responsible for maintaining more than 57,000 miles of roadway. A large part of this maintenance effort comprises the implementation of VDOT's snow removal and ice control program. As a result, VDOT purchases approximately 500,000 tons of sodium chloride annually. These chemicals are stored and managed at over 300 salt storage facilities throughout the Commonwealth. The Department has undertaken a number of research projects with the intent of identifying and developing methods to minimize the potential environmental burdens associated with salt storage. These efforts include salt- laden stormwater characterization, minimization, storage, treatment, and reuse. The findings and outcomes of each of these efforts will be discussed. First went to work for the Virginia Department of Highways in 1967 as a Survey Party Roadman during the summers while attending the University of Virginia. Background includes Highway Design & Construction, Construction Management, and Maintenance Management. Jimmy completed the VDOT Engineer Training Program and participated in the construction of Several Major Bridge Projects and Two Underwater Tunnel Projects in the Hampton Roads region of Virginia. Jimmy served as the Resident Engineer in Lexington, VA for 20 years where he managed the Maintenance and Construction Program for a 3 County Area with 100 centerline miles of Interstate Highway and more than 1,500 miles of Primary and Secondary Highways. In his role as Implementation Coordinator Jimmy is responsible for the implementation of new technology and research recommendations. Recently completed the refurbishment of the Mixing Pad runoff management at nearly 200 Maintenance Areas across Virginia, led the implementation of the production and use of Salt Brine for anti-icing operations. Currently leading projects to recycle mixing pad and vehicle wash water into salt brine production. Pollution Prevention Efforts for Managing Winter Maintenance Chemicals: A Research Summary Jimmy White Implementation Coordinator BACKGROUND • VDOT typically purchases over 500,000 tons of NaCl each year • Chemicals are stored and distributed out of 300+ salt storage facilities • Each has covered storage and open loading pad • Runoff from loading pads directed to stormwater ponds 3 Storage Site Locations 4 Typical VDOT Salt Storage Sites 5 PROBLEM • • • • 6 VDOT is collecting a lot of water Evaporation is not always sufficient Chloride levels are high Disposal options are limited and costly RESEARCH APPROACH 1. Characterize extent of runoff problem – – – Quantity Quality Disposal options and costs 2. Examine Management Options – – 7 Minimize capture Storage options RESEARCH APPROACH (cont.) 3. Examine relevant treatment technologies – – – Reverse Osmosis Ion Exchange Electrodialysis 4. Determine feasibility of recycling stormwater – – – – 8 Determine effect of “contaminants” on resulting brine Determine what filtering is necessary Determine quantities of brine potentially used by VDOT Cost analysis PROBLEM CHARACTERIZATION 9 Water Quantity • Annual Treatment Volumes (million gallons) • Winter Treatment Volumes (million gallons) – Minimum = 19 – Average = 31 – Maximum = 36 Volume (million gallons) – Minimum = 35 – Average = 59 – Maximum = 88 100 Annual Volumes 60 Winter Volumes 40 20 0 Maximum Average Minimum Annual Rainfall 10 80 WATER QUALITY • Chloride – 140 to 3100 mg/L – 1600 mg/L average • TSS – 3 to 270 mg/L – 20 mg/L average • Oil and Grease – 0 to 193 mg/L – 2 mg/L average 11 MANAGEMENT OPTIONS 12 Reduce Volumes 13 Reduce Impervious Area 14 Add Diversion Valves 4/13/2015 15 Tank Storage Instead of Ponds 4/13/2015 16 TREATMENT 17 Technologies Investigated • Ion Exchange • Electrodialysis • Reverse Osmosis – – – – – Most promising of the three Could reach target concentration for Cl Low cost ($0.05/gallon) Portable Waste stream may be reusable • Cons – Unknowns: maintenance and pre-filtering requirements 18 Reverse Osmosis Pilot • Laboratory tests – Removal efficiencies – Maintenance issues • Field tests – True cost of operation – Maintenance issues – Unforeseen problems 19 Reverse Osmosis Pilot • Maximum 50% volume reduction • Pre-filtering is not feasible with current system • System throughput is too slow • Manpower requirements • Still have not addressed regulatory limit or fate of product stream RECYCLING 21 Recycling Tests • Produced brine in lab using impaired influent water: – 100-5000 mg/L Cl– 0-100 mg/L TSS – 0-20 mg/L Oil and Grease – Varying temperatures • Produced brine in field using salt water from VDOT site Recycling Volumes Potentially Used Recycling Conclusions • Existing salt concentrations, TSS values, and oil and grease levels do not inhibit the production of brine • No additional pre-filtering is required • Significant cost savings could result from the use of brine, depending on the volumes generated QUESTIONS? 4/13/2015 25