Core Materials

advertisement

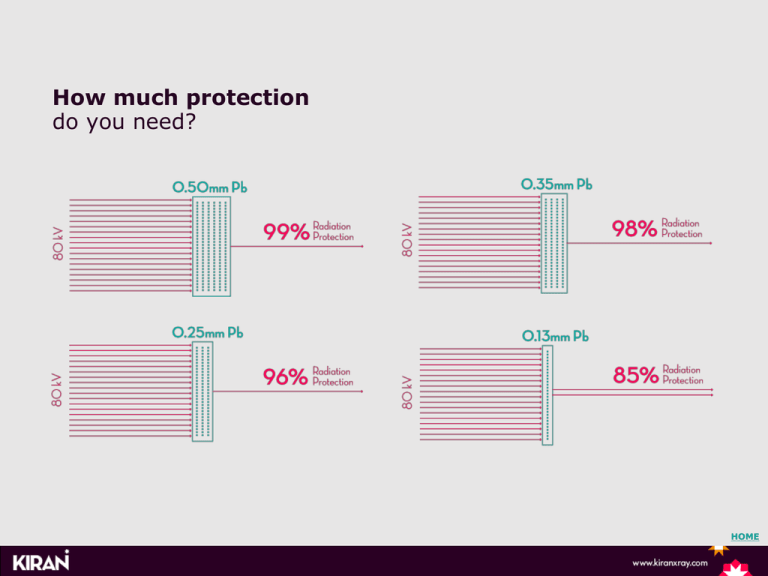

How much protection do you need? HOME What differentiates a good and not-so-good apparel? Protective Material: Quality & Weight Comfort & Ease of Use Application Based Design Covering Fabrics Suitability Workmanship & Consistency HOME Protective Material Types Lead Light Lead No Lead HOME What about Lead Material? • Traditional lead rubber sheeting has been used for over 60 years for making protection apparel. • Even in 21st century, lead continues to be an excellent x-ray protection material. • It is particularly useful in procedures that last a short period eg for a conventional x-ray. HOME Why are some Lead Materials heavier than others? Leaded protective material can be made in many ways: 1. 1st generation protective materials used Lead Oxide rather than with Lead powder. Weight of oxide is unnecessarily adds to apron weight. This process is used in making over 60-70% of lead protective material even after over 60 years . This type of material is used by a large number of manufacturers all over the world as it is the cheapest material. 2. New technology developed in mid 80s used Lead powder instead of lead oxide. 3. If the lead powder contains a high percentage of impurity ,weight of product will be that much higher. 4. Furthermore, in both lead oxide and lead powder, binding material (typically rubber or vinyl) is used to make sheeting. a. In most materials this is nearly 20% of the weight of lead or lead oxide. b. In the new generation materials this is only 10-12% of the weight of lead powder. Kiran’s LEADLITE is the best of such material developed after extensive research and development with its proprietary formulations . HOME Lead vs Lead! 4.0 3.6 Weight In Kg/Sqm 3.3 (Weights are for 0.25 lead equivalence) 1st Generation Lead Oxide Materials Kiran’s Lead Materials with high binders and/or impurities Kiran’s Material Material is the lightest possible leaded material HOME Lead Apron vs 5.4 4.7 4.2 Weight In Kg Coat apron made from 1st generation Lead oxide market. Coat apron made from Lead Materials with high binders and/or impurities Coat apron made from aprons are 22% lighter than any other lead aprons available in Comparison for a apron of size 100X60 with a protection of 0.5 mm Pb @^#$& my back! Why Light Lead? Long hours of wearing a heavier apron particularly during surgeries and in cathlab leads to discomfort, pain and risk of back problems. Light weight aprons reduce the load on the back and provide relief. HOME Why is Light Lead lighter than Lead? Certain elements of the periodic table have good X-ray blocking properties similar to that of Lead. Eg: Tin, Antimony, Bismuth, Tungsten An optimum combination of several such elements in a mixture with pure lead powder results in approximate 30% lower weight compared to conventional lead sheeting. HOME Light Lead vs Light Lead! Weight In Kg/Sqm 3.3 2.7 (Weights are for 0.25 lead equivalence) Most Light Lead Materials Kiran’s Material Kiran’s represents the state of the art of light lead compounding technology. HOME Lead Apron vs. Vs 5.8 4.4 3.8 Weight In Kg Double side apron made from Lead oxide Double side apron made from Double side apron made from aprons are 34% lighter than any other lead aprons available in market and 14% lighter than Comparison for a apron of size 100X60 with a protection of 0.5 /0.25 mm Pb Why do we need No Lead? Lead is toxic, carcinogenic and harmful to the environment. The need is for a radiation protective material that is as light as light lead but not an environmental hazard. HOME No Lead vs No Lead! 3.3 Weight In Kg/Sqm 2.7 (Weights are for 0.25 lead equivalence) Most No Lead Materials Kiran’s Material Kiran’s has been developed using the best lightweight technology, eliminating all lead and using mineral oils instead of plasticizers . HOME Kiran uses the best protection made yet! HOME