Risk_Assesment

advertisement

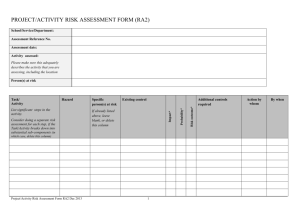

HSC on board library – CBT 7 Course Format Course is made up of this power point presentation accompanied by the short questionnaire next to you! Please ask an agency employee to assist whenever required. You can advance through the presentation by hitting the “ENTER” key with your desired speed! You should be able to complete in 2 hours CHECK ON YOURSELF Please read the questionnaire and answer the questions to your best knowledge without consulting this presentation or an instructor. Be fair to yourself! Complete it (not more than 8-10 minutes), Turn it around and continue here. The chance of an adverse event The likelihood of hazard being realised The combination of the probability, or frequency of occurrence of a defined hazard and The magnitude of the consequences of the occurrence. You should know 3 Common areas of risk to the company and shipboard staff: RISK TO HEALTH AND SAFETY 1. Risk to Health and safety, Consequences are injuries and fatalities 2. Risk to Environment, Consequence is pollution, etc 3. Risk to Operations, consequence are broken equipment, damaged cargo, off-hire, etc RISK TO ENVIRONMENT COST RISK TO OPERATION HOW DO WE MANAGE THE RISKS? Through the procedures By Safety management system We will not have accidents. What is the result if we make enough regulations ?? Principles of risk Management Ask yourself these questions 1. 2. 3. 4. What are the risks in shipboard operations? How often are you or your crew, at risk What are the consequences of an accident? What can you do about it ????????????????????? Risks in Lifeboat Drills (for example) Killed more than safe ? UK marine Accident investigation Branch’s database, accumulated over 10 - year period, Indicate the lifeboat and launching system cost the lives of 12 seafarers. ( 16% of total lives lost on UK flagged vessels) X 12 Seafarers + 87 seafarers injured X 87 Seafarers It happened during drill and training What’s wrong ??? Too late for us, but don’t forget Risk Assessment and Incident Investigation for the rest of our colleagues who are still alive !!! DAMAGE OF L/BOATs DURING DRILL What is the purpose of Risk Assessment ? The purpose Is to ensure that careful examinations of shipboard operations are carried out to determine what can cause harm that existing controls are adequate determine or risk levels are tolerable. Objective of Risk Assessment The Objective Where risk level are unacceptable, to identify and implement appropriate controls to reduce risk levels to as low as reasonable practicable Expected outputs of a Risk Assessment ???????? Minimisation of risk to people and the environment Improvement in operational performance Assist on establishing a responsible image within the marketplace How do accidents happen! Accident Near Misses Unsafe ships Lack of Safety Culture Lack of shipboard teamwork Affects of Operation Performance Social well being of seafarers Successful safety Management There is an absolute link between the social well being of seafarers and a successful Safety Management System onboard! Regulations could reduce level of Risk HIGH Level of risk REGULATIONS RISK MANAGEMENT LOW Safety assessment process Identification of Hazards Risk assessment Risk control options Cost benefit assessment Recommendations for decision making Risk Assessment Programme • Make sure shipboard personnel aware that company is serious about risk assessment • Ensure procedure are in place before commencement • Provide training 1. Purpose and objective 2. Identifying the hazards and controls • Identify who should carried out the risk assessment 1. Experience person 2. Old + Young = Experience + Objectivity 3. Assessing risk 4. ALARP ( as low as reasonably practicable) $$$$$$$ 5. Review processes Review RISK ASSESSMENT PROCESS COMPRISES 7 STAGES • Inventory of shipboard operations • Identify hazards • Identify existing controls • Determine risk • Decide if risk is tolerable • Implement Controls • Review assessments Inventory of shipboard operations • Importance to list and categorize all shipboard operations Operation type Operation group Deck Vessel Integrity Man on deck in heavy weather Engine Routines Watchman doing round check in darkness Mooring Lowering/Launching of L/B and MOB boat Cargo Navigation Operation Entering cold weather Which Operations do you assess FIRST ??? First SELECT those that have a potential for loss which could do most harm to 1. 2. 3. 4. people, property, the environment, the reputation of the company. Identify hazards, what causes an accident? Consequences Accident Direct causes Indirect causes Root Causes Lack of management, poor Management, lack of controls Falling, slipping, fire, Explosion, Oil spill, Collision, Grounding, system Failure Unsafe Acts Smoking, not wearing PPE, Ignoring safe working practices Unsafe Conditions Job factors Personal factors Lack of control Dark, noisy, toxic/explosive Atmosphere , Design, equipment, manning Fatigue, lack of training, Organisation or Familiarity For Example Accident - Ship runs aground Direct Cause - Duty Officer set wrong course on Auto-pilot. Indirect cause - Fatigue due to lack of rest prior to bridge watch Root cause - Company policy on rest periods not fully implemented CREATING SAFE WORKING ENVIRONMENT 1st STEP (KEY POINT) HAZARDS IDENTIFICATION 2ND STEP CONTROL Will Cause MINIMISE THE HAZARDS RESULT SAFE OPERATIONS Difference between Hazard and Event Hazard Event Slippery Surface Slipping causing a minor injury Corroded ladder Rung collapsing causing bruised/cut foot Combustible atmosphere Explosion causing fatalities Toxicity Inhalation causing fatalities Darkness Banging head or tripping causing minor injury Depending on the nature of the operation, the consequences of an event can have different levels of severity; darkness may have a greater impact on the entry into enclosed spaces than on navigation, Ask following 3 questions which could you help to find hazards and the nature of the harm, 1. Is there a source of harm? 2. Who or What can be harmed? 3. How could harm occur? Identify Existing Controls Controls can fall into following categories 1. Procedure – the majority of the controls will be in the form of procedure 2. Environment – For example – oily / water separator 3. Personal Protective Equipment (PPE) - For example – Breathing Apparatus, Gloves 4. Human Element – For example: Rest periods, training 5. Design/engineering – For example: Increasing the strength of hatch covers, fitting hoops around ladders How to determine the Risk ? is the combination of 1. The likelihood of the hazardous event occurring 2. The severity of the consequences Assessing Likelihood Likelihood Occurrence Highly unlikely < Once per year per fleet Unlikely < Once per year per ship Likely < Once or more per year per ship Consequence Level……. Needs to be determined for possible harm to people, ship and/or the environment For Example……………………………… Consequence Effect Slightly harmful Harmful Extremely harmful cuts, bruises, headaches or discomfort due to surrounding environment. Requires first aid, but able to resume work next day. Minor pollution, unacceptable funnel emissions Laceration, burns, temporarily disability Unable to return to work within 3 days or requires repatriation Moderate pollution, Onboard oil spill contained Amputations, major fractures, multiple injuries, poisoning or fatal injuries Unable to resume sea-going employment Major pollution, Overboard oil pollution Qualitative Risk Table Once you have determined the likelihood and the level of consequence, you can determine the level of risk using the qualitative risk table Consequence Likelihood Highly unlikely Slight Harmful Trivial Risk harmful Tolerate Risk Extremely harmful Moderate Risk Unlikely Tolerable Risk Moderate Risk Substantial Risk Likely Moderate Risk Substance Risk Intolerable Risk Decide if Risk is Tolerate Risk Trivial Tolerate Moderate Substantial Intolerable Action ~No action is required and no documentary records need be kept. ~No additional controls are required. consideration may be given to more cost effective solution of improvement that imposes no additional cost burden. Monitoring is required to ensure that controls are maintained. ~Effort should be made to reduce risk. but the costs of prevention should be carefully measured and limited. ~Work should not be started until the risk has been reduced. Considerable resources may have to be allocolated to reduce the risk. Where the risk involves work in progress, Urgent action should be taken. ~Work should not be started or continued until the risk has been reduced. If it is not possible to reduce the risk even with unlimited resources, Work has to remain prohibited. ALARP PRINCIPLE Increasing Level of Risk Unacceptable Region Tolerable Region Risk can’t be justified unless there are acceptable reasons Tolerable only if risk reduction is impracticable or if its cost is grossly disproportionate to the improvement gained Tolerable if cost of reduction would exceed the improvement Broadly acceptable region Necessary to maintain asssurance that Risk remains at this level For following example for personnel to Enter Enclosed space with minimum control 1. Unacceptable region of ALARP It would be unacceptable for personnel to enter oil cargo tank when full of oil or not gas free as the risks are too high It is within the bounds of reason however, expect this to happen under exceptional circumstances, i.e. rescue 2a.Tolerable region of ALARP (Upper Zone) Enter to empty fuel oil Tank Risk to personnel of entering the tank could be high BUT not as high as full tank To drive down the risk vast amount of money involved (designing and fitting hi-tech ventilation, lighting system, etc) The cost of such measurement would be grossly disproportionate to the improvement THEREFORE OPERATION IN ITS PRESENT STATE IS TOLERABLE AND RISKS ARE REDUCED TO LEVEL THAT CAN BE CONSIDERED ALARP. 2b.Tolerable region of ALARP (Lower Zone) Enter into empty and well ventilated fresh water tank Generally operation with Tolerable risk level If harm occurs, it is more likely the result of a consequence of an individual’s action rather than from any inherent properties of MT tank. To drive down – need low or moderate expense But could be considered unnecessary as current Risk levels are already ALARP 3.The Broadly acceptable region of ALARP In this region……………… Risks are regarded as trivial + Adequate controls are in place Review should be in place No further action required unless reasonable practicable measures becoming available or Required by Law or Industry convention Guidance on selecting Controls Remove or eliminate the hazard Contain the hazard Use technology to monitor the hazard Adapt the individual to the work Personnel Protective Equipment Emergency Response Re- design, Re-equip Review on Assessment Risk level should be TOLERATE RESIDUAL RISK should be as low as reasonably practicable ANY NEW HAZARDS created should be acceptable FEEDBACK from personnel on planned controls SUGGESTIONS for improvement