HOT WORK

advertisement

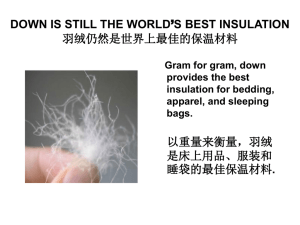

HOT WORK Up to 25 percent of fatalities in shipyards result from fires and explosions caused by hot work. (Bureau of Labor Statistics USA) Helen Verstraelen HOT WORK? Cutting and welding operations for construction / demolition activities that involve the use of (portable) gas or arc welding equipment. Gases frequently used: Acetylene Oxygen HOT WORK ACETYLENE ACETYLENE C2H2 Fire and explosion data: Flash point: -18°C Auto ign. Temp.: 305°C LEL: 2,5%; UEL: 100% Extinguish with CO2 or dry chemical Health hazard data: Asphyxiant, irritant and anesthetic no TLV, about 100mg/l may be tolerated for 0,5 to 1 hour No chronic harmful effects evidence Thermal burns possible ACETYLENE Stored in cylinder Completely filled with porous filler material diatomaceous earth charcoal asbestos (strengthener) cement (binder) Acetone used to solve the acetylene ACETYLENE Always keep cylinder in upright position Prevent loss of acetone and so reduce the cylinder’s ability to hold dissolved acetylene Handle with care Dropping can cause leakage Filler can break and cause voids where acetylene can accumulate and decompose Cylinders designed for temp up to 52°C ACETYLENE Keep flammable gas cylinders from oxidizing gas cylinders Soap test regulator, torch, hose and cylinder connection before placing acetylene equipment in service Move leaking cylinders to open area In most cases, it is best to allow a burning acetylene cylinder to burn itself out Keep valves closed when not in use OXYGEN Fire and explosion data: NA Oxygen is nonflammable, but supports and vigorously accelerates combustion of flammables. Some materials non combustible in air, will burn in the presence of oxygen Materials that burn in air, will burn violently in atmosphere richer than approx 25% Oxygen OXYGEN Health hazard data: NA Non toxic under normal conditions, necessary to support life Liquid oxygen or cold gas will freeze tissues and can cause severe cold burns Oxygen at higher concentrations can produce cough and chest pain 100% within 8 to 24 h 60% within several days Much quicker under high pressure, also other nervous system malfunctions WELDING HEALTH PROBLEMS Gases and fumes Inhaling toxic gases from base material, filler material, coatings, paints, shielding gases, chemical reactions, contaminants in the air. Effects are different for each gas. Short and long term reactions from fever to cancer Heat Can cause burns, eye injuries, heat stress or heat stroke WELDING HEALTH PROBLEMS Radiation UV radiation: Burns can occur without prior warning. “Arc-eye”. UV reacts with O and N to form ozone and nitrogen oxides. These are toxic and can cause lung diseases IR radiation: May heat the skin and the tissues below the surface. Visible light: Can cause adaptation and shading of the eye, to protect the retina. Noise Musculoskeletal injuries UNSAFE PRACTICES No competent fire watch Combustible materials, vapors not moved Hot work near heavy concentration of dust or combustible vapors Proper type of fire extinguisher not at the scene Oxygen and gas cylinder not in upright position Oxygen and gas hoses with mechanical damage No shutoff valves Hoses not removed after work REDUCING RISKS Identify hazards (type welding, materials used, environment) Use safety data sheets Eliminate or substitute hazardous materials Make sure workspace is proper ventilated Use Shielding Follow safe working practices REDUCING RISKS Monitor the air Welding only for proper trained personnel Complete the hot work permit and stick to its requirements Wear personal protective equipment Helmet, goggles, clothing… Always used along with, but never instead of engineering controls and safe working practices. PPE HOT WORK PERMIT The hot work permit system is intended to educate the parties involved in construction of the hazards and to implement control measurements to help mitigate them. HOT WORK PERMIT HOT WORK PERMIT HOT WORK PERMIT HOT WORK The first question you should always ask yourself: CAN THE JOB BE AVOIDED? IS THERE A SAFER WAY? EXAMPLE: HOT WORK ON CARGO CONTAINMENT SYSTEMS OF GAS CARRIERS • In repair yards: cargo- and ballast tanks, pipes, void spaces are safe in terms of concentrations of O2, flammable and toxic gases • most tanks have some external thermal insulation • • • • • mineral wool perlite balsa wood polystyrene polyurethane INSULATION • mineral wool: • manufactured by melting volcanic rock and limestone and spinning the molten material into wool. • thermal insulation • passive fire protection • chemical inert • non combustible • open cell structure: thus capable of absorbing hydrocarbon liquids or vapours INSULATION • perlite: • finely powered volcanic rock • inert • can absorb liquid • used on refrigerated LPG tankers in ’60, ’70 and ‘80, treated with silicone to stick INSULATION • balsa wood: • open grain structure – very good insulation • used in early membrane systems • in case of fire: rapid spread because open structure • can absorb several times its own weight of water and therefore also petroleaum liquids or vapours INSULATION • polystyrene and polyurethane: • highly inflammable • covered with protective aluminium foil • when ignited, release large quantities of toxic, black smoke HOT WORK IN SHIPYARDS • Gas carriers under construction: • • • • Welding before insulation is fitted Insulation stored in safe place Beware for solvents in glues No self adhesive plastic protection. This will encourage spread of fire insulation material without and with plastic protection HOT WORK IN SHIPYARDS • Gas carriers in service: • Fully pressurised ships: • Generally not larger than 2000m³ • These ships do not need extra insulation • Easy to detect safe working conditions • No hot work casualties recorded for these type of ships HOT WORK IN SHIPYARDS • Gas carriers in service: • Semi pressurised vessels • Generally u to 20 000m³ capacity • Insulated with polyurethane foam, glued to the tank surface and covered with a galvanised steel or aluminium foil • Extra attention required when hot work is carried out • gas entered in insulation • solvents in glue • Fully refrigerated vessels • Most common • same insulation and precautions as above