Supporting Facility and Process Flows

Chapter 7

McGraw-Hill/Irwin

Copyright © 2011 by The McGraw-Hill Companies, Inc. All rights reserved.

Course Overview

Define, describe and classify services (Ch 1,2)

SPECIAL TOPICS

VIEWS

TOOLS

Information

technology (Ch 5)

Strategic view of

service design &

development (Ch 3,4)

Capacity planning &

queuing models

(Ch 11,12,16)

Supply Chains &

Outsourcing (Ch 13)

Process view of

quality improvement

(Ch 6,7,8)

Project management

(Ch 15)

Facility location

(Ch 10)

Globalization (Ch 14)

Encounter view of

customers &

employees (Ch 9)

Inventory control

(Ch 18)

2

Servicescapes

Designing Physical Surroundings to Affect Employee

and Customer Behavior

• Ambient Conditions: background characteristics

such as noise level, music, lighting, temperature, and

scent.

• Spatial Layout and Functionality: reception area,

circulation paths of employees and customers, and

focal points.

• Signs, Symbols, and Artifacts: selection, orientation,

location, and size of objects.

3

Environmental Orientation Considerations

• Need for spatial cues to orient visitors

• Formula facilities draw on previous experience

• Entrance atrium allows visitors to gain a quick

orientation and observe others for behavioral cues

• Orientation aids and signage such as “You Are Here”

maps reduce anxiety

• Allow customers to see both into and through the

space

4

Facility Design Considerations

• Nature and Objectives of Service

Organization

• Land Availability and Space

Requirements

• Flexibility

• Security

• Aesthetic Factors

• The Community and Environment

5

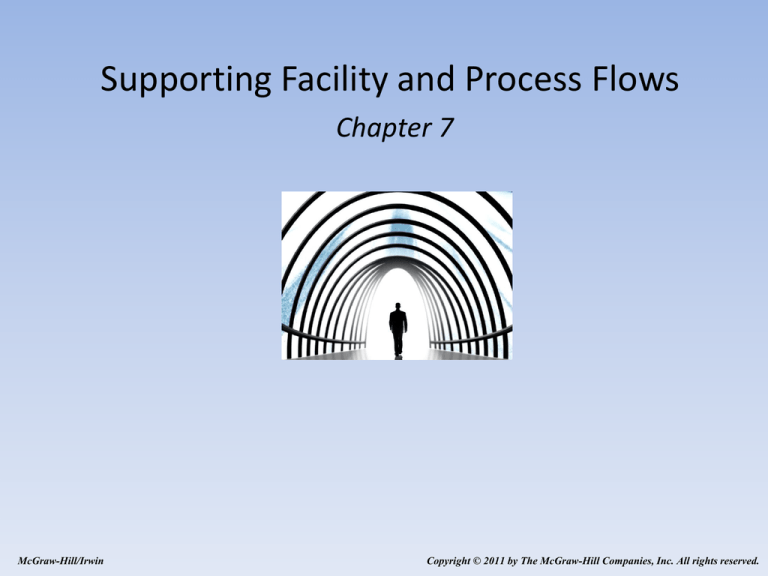

Types of Services Processes

Process Type

Service

Example

Characteristic

Management Challenge

Project

Consulting

One-of-a-kind engagement

Staffing and scheduling

Job Shop

Hospital

Many specialized departments

Balancing utilization and

scheduling patients

Batch

Airline

Group of customers treated

simultaneously

Pricing of perishable

asset (seat inventory)

Flow

Cafeteria

Fixed sequence of operations

Adjust staffing to demand

fluctuations

Continuous

Electric Utility

Uninterrupted delivery

Maintenance and

capacity planning

6

Process Flow Diagrams

• Visualize and document a process

• Identify bottlenecks

• Determine system capacity

• Make improvements

7

Process Flow Diagram of Mortgage Service

Property Survey

CT=90 min.

Completed

Applications

Mortgage

Applications

Yes

Final Approval

Approved

Mortgages

CT=15 min.

No

Accept

Mortgages

Credit Report

Title Search

CT=45 min.

CT=30 min.

Unapproved

Mortgages

Finish

Processing

8

Mortgage Service Process Gantt Chart

Rush Order Flow Time =

90 + 15 = 105 min

3

1

2

Process Cycle Time

Every 90 min a new

mortgage is completed

Slide contributed by David Hoyte

Fig. 7.5, pg 163

9

Process Analysis Terminology

• Cycle Time is the average time between completions

of successive units.

• Bottleneck is the factor that limits production usually

the slowest operation.

• Capacity is a measure of output per unit time when

fully busy.

• Capacity Utilization is a measure of how much output

is actually achieved.

• Throughput Time is the time to complete a process

from time of arrival to time of exit.

10

Process Analysis Terminology (cont.)

• Rush Order Flow Time is the time to go through the

system without any queue time.

• Direct Labor Content is the actual amount of work

time consumed.

• Total Direct Labor Content is the sum of all the

operations times.

• Direct Labor Utilization is a measure of the

percentage of time that workers are actually

contributing value to the service.

11

Bottlenecks

1) When flow is not

synchronized, process

rate is limited by the

“bottleneck”

2) The bottleneck

constrains throughput.

The rate of total

throughput is the rate of

the bottleneck

3) Time lost on the

bottleneck is time lost in

the whole process

Slide contributed by David Hoyte

12

Work Allocation – Boat Show

2

1

In

30

120

Collect

Payment

15

240

Hand Stamp

+ program

What is the Process Capacity?

Where is the Bottleneck?

What if 1 more person is added?

3

15

Out

240

Apply wrist

band

Capacity Calculation:

15 sec cycle = 4

customers per min

= 4 x 60 = 240

customers per hour

Activity

Number(s)

Capacity

per hour

Cycle Time

in seconds

Slide contributed by David Hoyte

13

Work Allocation – Boat Show

1

In

30

2

15

1

In

120

30

240

3

15

240

Out

120

Collect

Payment

Hand Stamp

+ program

Apply wrist

band

What is the Process Capacity now?

Slide contributed by David Hoyte

14

Options for Eliminating a Bottleneck

1. Add another worker to the job.

2. Provide aid to reduce activity time.

(e.g. automating an activity)

3. Regroup the tasks to create a new line balance

with different activity assignments.

• Goal: all jobs/activities should be of nearly

equal duration.

15

Automobile Driver’s License Office

2

1

15

In

240

Review

30

120

Payment

4

3

60

60

Violations

40

90

Eye Test

Activity

Number(s)

Cycle Time

in seconds

5

20

180

Photograph

6

30

120

Issue

Out

Capacity

per hour

16

Automobile Driver’s License Office

(Improved Layout)

In

1,4

55

65

3

60

60

2

30

In

1,4

55

65

3

60

120

5

20

180

Out

6

30

120

60

17

Health Maintenance Organization (B)

Activity

Time (sec.)

Receive prescriptions

24

Type labels

120

Fill prescriptions *

60

Check prescriptions *

40

Dispense prescriptions *

30

* Must be performed by Pharmacist

18

HMO (B) Questions

1. Identify the bottleneck activity, and show how

capacity can be increased by using only two

pharmacists and two technicians.

2. In addition to savings on personnel costs, what

benefits does this arrangement have?

19

HMO (B) Process Flow

Current staffing: 2 Techs & 3 Pharmacists,

each doing one task

Activity

1

2

3

150

24

Cycle

time

4

30

120

5

60

60

90

40

120

30

Capacity

per hour

What is the bottleneck operation?

What is the capacity of the system?

Why? How can capacity be increased?

Slide contributed by David Hoyte

20

HMO (B) Process Flow (old vs. new)

1

2

3

150

24

4

30

120

5

60

90

60

40

1, 2

30

25

144

What other benefit do

the two symmetrical

“cells” provide?

Slide contributed by David Hoyte

1, 2

2 Techs

120

25

144

Capacity

30 / hr

2 Techs

3 Pharma

3,4,5

27.7

130

3,4,5

Capacity

50 / hr

2 Techs

2 Pharma

27.7

130

21

The Role of the Servicescape

The Servicescape

Concept: a modern farmer’s market for the

discerning customer

•

•

•

•

Aesthetics

Force Flow

Queuing

Results

“We want to change the way people eat…” Brian Cronin, General Manager

23

Aesthetics

24

Force Flow

Seafood

Dairy

Bakery

Meat

Produce

Beer & Wine

Deli

Grocery & Staples

Produce

Cheese

Produce

Flowers

Cafe

Info

Coffee

Entrance

Cashiers

Exit

Catering

25

Normal Grocery Store

Dairy

Meat

Frozen

Produce

Grocery & Staples

Cashiers

Deli

26

Queuing Systems

Express Lanes

Checkout

Deli/Meat

6

1

5

3

4

2

27

Comparison

Central Market

60k ft2

Average Grocery Store

Size

100k ft2

Transactions / Week

25,000

$40

Wine

50,000

Sales / Customer

Product Mix

$20

Groceries

28

“There’s cheese at the end of the

maze…”

Questions

1. How do the environmental dimensions of the

servicescape (ambient conditions, space/function,

signs, symbols & artifacts) explain the success of

Central Market?

2. Comment on how the servicescape shapes the

behaviors of both customers and employees?

29