Nanomaterial Safety - ssunanotraining.org

advertisement

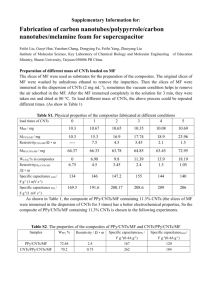

Safety and Industrial Hygiene of working with Carbon Nanotubes Nanotechnology is the engineering and manipulation of materials at the molecular level The dimension of nanomaterials are between 1 and 100 nanometers • 1nm is 1 billionth of a meter • A human hair is 50,000 nanometers in diameter Particles created at the nanoscale have different chemical and physical properties than larger particles of the same material Carbon Nanotubes (CNTs) in particular have unique electrical, mechanical, and thermal properties with a large potential in electronics, aerospace, and many other industries. • CNTs exist in two forms, single-wall (SWCNTs) and multi-wall (MWCNTs) Due to the relatively new nature of nanotechnology, research is still being conducted on the health hazards Two facts must be known to determine if workers are at risk • The type and concentration of nanoparticles in the workplace • The specific properties of the nanoparticles that could potentially affect the body Workplace exposure tasks that increase the risk of • Handling powders of nanomaterials • Maintenance on equipment and processes used to produce or fabricate nanomaterials and the cleaning-up of spills and waste material containing nanomaterials • Cleaning of dust collection systems used to capture nanoparticles • Machining, sanding, drilling, grinding, cutting, or other mechanical disruptions of materials containing nanoparticles In lab animals, some nanoparticles reach blood, brain, and other organs when inhaled This causes adverse effects such as inflammation and fibrosis in the lungs and other organs Recent studies have shown that size, surface area, surface chemistry, solubility, and possibly shape all play a role in determining the potential to cause harm Studies in workers exposed to aerosols of some manufactured or incidental microscopic and nanoscale particles have reported adverse lung effects including lung function decrements and obstructive and fibrotic lung disease CNTs may contain metal catalysts as byproducts of their production, which could contribute to their toxicity Regardless of the process by which CNTs were synthesized and the types and amounts of metals they contained, CNTs were capable of producing inflammation, epithelioid granulomas (microscopic nodules), fibrosis, and biochemical/toxicological changes in the lungs SWCNTs have been shown to produce adverse effects at mass doses at which ultrafine carbon black did not produce adverse effects. Both are carbon based but SWCNTs have a unique structure SWCNTs were shown to be more toxic than quartz, which is considered a serious occupational health hazard if it is chronically inhaled MWCNTs have been shown to produce lung lesions similar to those observed in studies with SWCNTs These results indicate that, if CNT particulates reach the lung in sufficient quantity, they will produce a toxic response These studies do not answer the important health risk question of whether airborne CNT particles can reach the lungs, because in all cases the CNTs were placed inside the lungs of animals, not inhaled The lungs aren’t the only organ affected by CNTs • Studying the effects on mouse hearts, scientists found damage to the DNA, an increase of plaque in the aortic area, and an increase of atherosclerotic lesions in the brachiocephalic arteries The risk of nanotubes is often compared to that of asbestos Exposure to asbestos is not the same exposure that could occur with CNT’s. According to Lance Criscuolo, president of Zyvex Performance Materials, an Ohiobased company that uses CNTs, “CNTs, once mixed into a polymer matrix, are bound up and no longer releasable into air or water.” This means the workers in most concern are the ones actually creating the CNTs and putting them into plastics The EPA is most concerned with the fibrous, dry powder and less concerned with CNTs that are integrated into polymer materials, said David Burton, General Manager, Applied Sciences Inc. Criscuolo said Zyvex has done air monitoring studies throughout the entire process. “These studies were performed by a certified company. They were not able to detect any significant amount of CNTs in the airstream. This testing was also included in the composite cutting and sanding area. This provides some solid evidence that once CNTs are encapsulated within a resin system, that they are not able to become free from that system.” Inhalation • This is the most common and most dangerous type of exposure • It has been determined that the factors that have a role in pulmonary toxicity include, but are not limited to: particle number and size distribution dose of particle to target tissue surface treatment on particles the degree to which engineered nanoparticles aggregate/agglomerate surface charge on particles particle shape and/or electrostatic attraction potential method of particle synthesis – i.e., whether formed by gas phase or liquid phase synthesis and postsynthetic modifications, which likely influence aggregation behavior. Ingestion • Nanoparticles may enter the gastrointestinal tract as they are cleared from the upper respiratory tract and they appear to pass through relatively quickly • It is known that some nanoparticles, specifically nanotubes and nanofibers, can undergo surface oxidation and length shortening in presence of strong acid conditions, so it is possible that the acidic gastric environment will not only be unable to destroy the nanoparticles, but it may functionalize and shorten the particles to a point that their toxicological effect on the surrounding environment might change drastically Dermal • Some studies show that nanoparticles may penetrate the skin due to their small size. This possibility is being investigated Traditional industrial hygiene sampling methods can be used to measure airborne nanoparticles • Scientists are developing more sensitive and specific sampling techniques Workers need the development of sensors that simultaneously detect airborne nanoparticles and determine their potential to generate reactive oxygen species- possibly providing early indications of harm These materials are used in the production of the CNT’s Employers should use engineering controls to reduce workers exposure to nanoparticles • Source enclosure Isolating the generation source from the worker • Local exhaust ventilation systems Exhaust ventilation systems that use HEPA filters are effective in removing nanoparticles (See next slide) Prevent food and beverages in workplaces where nanomaterials are handled It’s a good idea to systematically evaluate exposure to ensure that control measures are working properly and that workers are being provided the appropriate personal protective equipment Existing U.S. regulations do not specifically address nanomaterials The EPA apparently intends to designate CNT releases into US waters as a “significant new use,” which would likely trigger a major amount of additional compliance recordkeeping for companies For a specific examples of a protocol for handling of nanotubes see: • PROTOCOLS FOR HANDLING NANOTUBE COMPOSITES.doc • C-nano Material Safety Data Sheet.pdf EPA is issuing significant new use rules (SNURs) under section 5(a)(2) of the Toxic Substances Control Act (TSCA) for two chemical substances which were the subject of Premanufacture Notices (PMNs). The two chemical substances are identified generically as multi-walled carbon nanotubes (MWCNT) (PMN P–08–177) and single-walled carbon nanotubes (SWCNT) (PMN P–08–328). This action requires persons who intend to manufacture, import, or process either of these two chemical substances for a use that is designated as a significant new use by this final rule to notify EPA at least 90 days before commencing that activity. EPA believes that this action is necessary because these chemical substances may be hazardous to human health and the environment. Exclusions include: • After they have been completely reacted (cured); • Incorporated or embedded into a polymer matrix that itself has been reacted (cured); or, • Embedded in a permanent solid polymer form that is not intended to undergo further processing except for mechanical processing. Personal Environmental Monitors can detect the amount of nanomaterials in the air that a worker is exposed to • This is crucial in the production of nanomaterials • Examples of PEMs Inhalation and ingestion protection can be provided by respirators • Must be(NIOSH)-approved air-purifying, tight- fitting full-face respirator equipped with N100 filters) Ingestion protection can be aided by frequent washing of the hands and maintaining a clean work environment Dermal penetration can be prevented by the use of nitrile gloves and full-coverage lab coats Accidental spills of nanotubes are inevitable during their production, and the massive use of nanotubes-based materials could lead to increased environmental pollution Research is being conducted to help aid in this situation • Scientists have found that CNTs deteriorate when exposed to the natural enzyme horseradish peroxidase, also called HRP • Once fully developed the method could be administered as easily as chemical cleanups in today’s labs The use of HEPA filtered vacuums and/or wet wiping techniques should be use often to keep the workplace clean Workers must wash hands frequently Setting up conforming hazardous waste management practices is a good idea