Lecture 1 – Putting Safety Into Perspective

advertisement

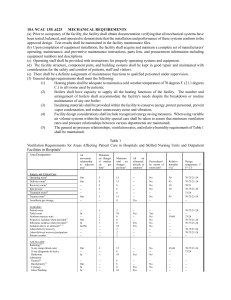

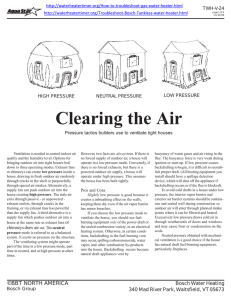

Industrial Ventilation - A major control measure Dr. AA, UTM Part 1 - Introduction What Is Industrial Ventilation? Environmental engineer’s view: The design and application of equipment for providing the necessary conditions for maintaining the efficiency, health and safety of the workers Industrial hygienist’s view: The control of emissions and the control of exposures Mechanical engineer’s view: The control of the environment with air flow. This can be achieved by replacement of contaminated air with clean air 3 Why Industrial Ventilation? To maintain an adequate oxygen supply in the work area. To control hazardous concentrations of toxic materials in the air. To remove any undesirable odors from a given area. To control temperature and humidity. To remove undesirable contaminants at their source before they enter the work place air. 4 Types Of Industrial Ventilation Systems 1. Supply systems To create a comfortable environment in the plant i.E. The HVAC system To replace air exhausted from the plant i.E. The replacement system 2. Exhaust Systems An exhaust ventilation system removes the air and airborne contaminants from the work place air The exhaust system may exhaust the entire work area, or it may be placed at the source to remove the contaminant at its source itself 5 Supply Systems Components Air inlet section Filters Heating and/or cooling equipment Fan Ducts Register/grills for distributing the air within the work space 6 Exhaust Systems Types of exhaust systems: General exhaust system Local exhaust system 7 General Exhaust Systems Application • Used for heat control in an area by introducing large quantities of air in the area. The air may be tempered and recycled. • Used for removal of contaminants generated in an area by mixing enough outdoor air with the contaminant so that the average concentration is reduced to a safe level. Two Types • Natural Ventilation: uses wind or thermally induced convection to induce air flow. • Mechanical Ventilation: Uses fan (with or without duct) 8 Local Exhaust Ventilation (LEV) The objective of a local exhaust system is to remove the contaminant as it is generated at the source itself. Advantages: • More effective as compared to a general exhaust system. Remove contaminant before it has a chance to spread. • The smaller exhaust flow rate results in low heating costs compared to the high flow rate required for a general exhaust system. • The smaller flow rates lead to lower costs for air cleaning Components: • Hood • The duct system including the exhaust stack and/or recirculation duct • Air cleaning device • Fan, which serves as an air moving device 9 Local Exhaust Ventilation Exhaust outlet Ducting Hood or exhaust inlet Fan and motor Filter or purifying system Ducting What is the difference between Exhaust and Supply systems? 11 End of Part 1