MS PowerPoint () format

advertisement

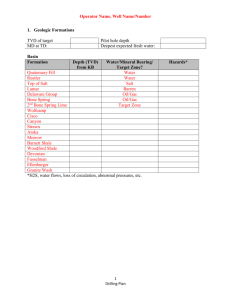

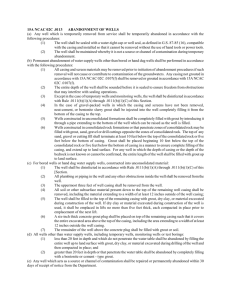

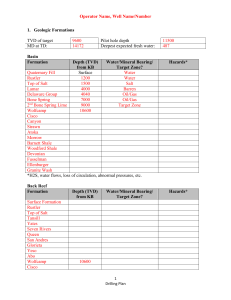

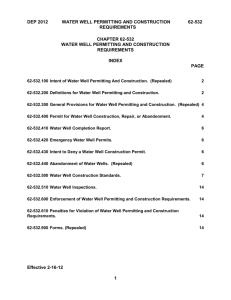

Norse Energy Corp., USA As natural gas assumes a far more important role in America’s energy mix, Norse Energy is committed to exploring, developing, producing, and marketing gas to the burgeoning premium markets of the metropolitan northeastern United States. Exploring growth opportunities for business in the local area Objective: To provide a brief overview of our operations, and explain our practices. Start of a Natural Gas Well Lifecycle Pre Planning: In house Geology Department to gather and evaluate subsurface information Obtain data using seismic testing and information from existing wells Input from Engineering, Marketing, and Pipeline divisions for feasibility and economic analysis Permitting and Regulations: NYS DEC Drilling Permit approval requirements: • Survey well location, Environmental Assessment Form, and unit verification • Storm Water Pollution Prevention Plan (SWPPP) establishes erosion and sedimentation plans and procedures for State Pollutant Discharge System (SPDES) • Drilling Procedures: Formations to be encountered, casing design, cement types and volumes, and wellbore path Additional regulatory agencies: OPRHP, Army Corps. of Engineers, NYSDOT, County and Towns, NYS PSC (pipeline), and the SRBC (water withdrawal) Start of a Natural Gas Well Lifecycle Site Selection After a site is selected by Geology, field work is coordinated with Land and Environmental to determine the feasibility of a well at that location. • Land owner is notified of potential well • Access road, well site, equipment placement and pipeline route approval is received from land owner Spacing Units Once a site is determined to be feasible, Land Dept. will generate the spacing unit. The spacing unit is prepared in accordance with NYS DEC regulations and requires their approval. Spacing Unit Examples (As per NYS DEC Regulations) For our current Herkimer wells the following spacing units are in place: 80 Acre units for a depth above 4,000’ 160 Acre units for a depth of 4,000-6,000’ 320 Acre units for a depth of 6,000-8,000’ Natural Gas Well Lifecycle Drilling of the Well Site Construction When all permitting is in place, the access road and well site are constructed in cooperation with the landowner. This activity is regularly inspected and monitored by the governing agencies. Drilling and Casings Spud the well and set conductor if needed Drilling surface hole (usually 12 1/4”) and install the surface casing string (usually 500’) of 9 5/8” and cement the casing to surface Install and pressure test the Blow Out Preventer (BOP) (This is done on each string of casing as per NYSDEC regulations) Drill intermediate hole (usually 8 3/4”) and install intermediate casing sting (usually 2,000-3,500’) of 7” casing and cement to surface, begin kick at this point. Drill main horizontal hole (usually 6 1/4”) using directional motors • Install production casing if required (usually 4 1/2”) and cement Present Herkimer Sandstone wells are coming in naturally and do not require the production casing. Natural Gas Well Lifecycle: Completions and Hydraulic Fracturing Completion Procedures If production casing is installed and cemented, the following procedure is followed to complete the well • Production casing is then perforated along the horizontal at precise intervals to open pathways through which the frac job can be performed and gas will flow. • During the initial portion of the frac job, water is pumped from the surface under pressure to create fractures in the rock formation underground. Once the fractures are established, a water/sand combination along with a small amount of other compounds is pumped into the fractures to prop them open. • Hydraulic Fracturing fluids are typically 99.5% sand and water, with the .5% remainder consisting of DEC approved compounds. NYS DEC Regulations Currently NYS DEC Regulations allow a maximum of 80,000 gallons of water for Hydraulic Fracturing of a well. New Regulations (sGEIS) are pending which will cover large volume Fracturing used in horizontal shale wells. Natural Gas Well Lifecycle: Restoration, Pipeline, and Marketing Restoration All free fluids are removed from the pit by a NYS licensed hauler and disposed of at a NYS approved disposal facility. The pit, which stores drill cuttings and fluids, has a 20 mm lining which is folded over and covered after the free fluids are removed. Transitioning to Pitless The well site is then filled back and the top soil replaced to allow seeding and mulching to be done. Final restoration is inspected by NYSDEC for regulatory compliance. Pipeline The well line is installed from the well to a gathering system. The gathering system transports gas from individual wells to a compressor facility. Compressor facilities are required to increase gas pressure which allows it to feed into transmission lines All pipelines are regulated by NYSPSC for safety and sometimes for environmental (dependent on spec’s some pipelines are regulated by FERC) Marketing Norse sells approximately 25% of production to NYSEG and used locally. Norse sells to the Dominion line, which services the East Coast including NYSEG Norse Energy Corp., USA Our Future in New York Surpassing Expectations and Piloting the Potential • • The Herkimer Sandstone Formation in this area is proving to be a very successful field. The Marcellus and Utica Shales, stretching throughout our core area, hold promise of success as well. Production Taxes • Production is currently taxed on a real property basis. • The rate is established based on a five year rolling average established by ORPS. • Tax revenues are applied locally: Schools, Towns, Counties, and Local Fire Departments. Questions?