Yale Cell Sorting Biosafety Program -

advertisement

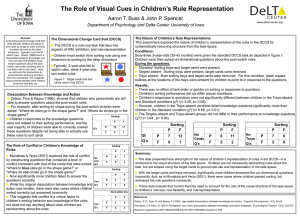

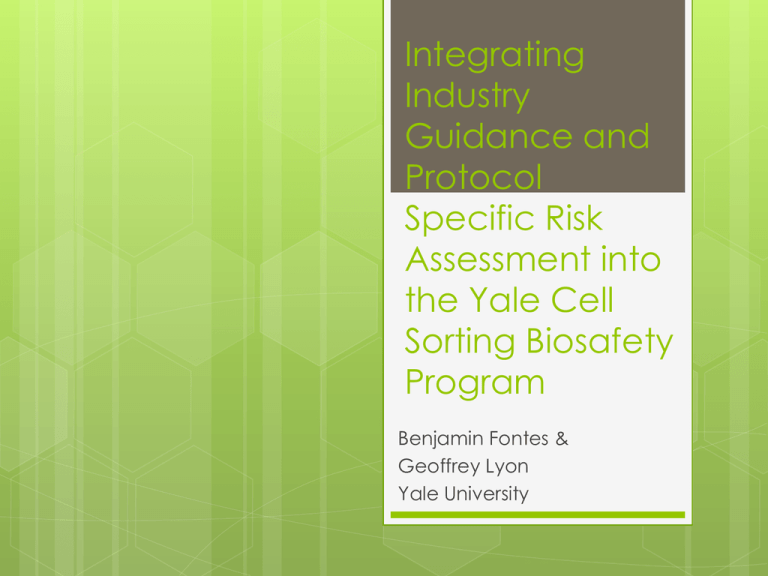

Integrating Industry Guidance and Protocol Specific Risk Assessment into the Yale Cell Sorting Biosafety Program Benjamin Fontes & Geoffrey Lyon Yale University Central Guidance Document • International Society for the Advancement of Cytometry (ISAC) Cell Sorter Biosafety Standards • Cytometry, Part A, Volume 85, Issue 5, pages 434453, May 2014 – • Ingrid Schmid, Kevin Holmes, Stephen Perfetto, Charles (Hank) Pletcher, Philip Hogarth, Simon Monard, Robert Wadley Pioneers (Schmid, Perfetto, Holmes) – Pletcher, Lyon, Lopez…. – Your institution’s pioneer? 2014 ISAC Cell Sorting Biosafety Standards Updates (augmentation of): Lab Design PPE Equipment specific SOPs Validation of aerosol containment Bacteriophage Glo-Germ Technetium-99 (UCONN – Wallace et al) Fluorescent beads (Pletcher & Lyon) NIH “next” (Holmes and continuous improvement) 2014 ISAC Cell Sorter Biosafety Standards Update Author(s) obsession (Schmid, Perfetto, Holmes…others) Obsessive in personal and researcher protection Obtaining data & continuous improvement Find your “obsessive” colleagues (Lyon @ Yale) 2014 Update “NIH Influence” 2014 ISAC Cell Sorting Biosafety Standards Industry Guidance Document Gives “NIH” recommended Biocontainment Does not take the place of Risk Assessment! Page 7, bottom of Table 2, footnote a “This list represents examples of biosafety level determination for cell sorting of specific agents. The final determination of the biosafety level is dependent upon the risk assessment conducted in collaboration with safety specialists, subject matter experts, and the IBC or equivalent.” 2014 ISAC Cell Sorting Biosafety Standards Flexibility Based on Risk Assessment Page 13 – 1st full paragraph PPE for BSL3 “Note that given the combination of engineering controls, aerosol evacuation system and instrument located within a certified biosafety cabinet, may, dependent upon a risk assessment, allow for alternate combination of PPE. This requires approval by the cell sorting operator/facility director, biosafety professional and the Institution’s biosafety committee.” 2014 ISAC Cell Sorting Biosafety Standards Flexibility Based on Risk Assessment Page 13, Last Paragraph before Appendix A: Alternate combinations of engineering controls, personal protective equipment and biosafety procedures that do not perfectly match the recommended BSLs may be selected. The final risk assessment SOP should be selected based on risk assessment and endorsed by the cell sorting facility manager, biosafety professionals and the IBC.” 2014 ISAC Cell Sorting Biosafety Standards Flexibility Based on Risk Assessment Page 12 3.1.1.2 Cell Sorters in biological safety cabinets …Class I BSCs enclosing cell sorters must be manufactured to meet functional certification criteria for personal protection as defined by the BMBL or EN 12469, although it is recommended that the inward airflow velocity be 100 linear feet per minute or greater; HEPA filters must be tested for leakage annually.” Key Messages in ISAC 2014 Introduction Work with manufacturers LAIs and aerosols Pertinent regulations Biosafety “Identify and evaluate agent hazards” BSPs Principles and Cell Sorting best at this “Identify laboratory procedure biohazards” Cell sorter operators best at this Key Messages in ISAC 2014 Biosafety Principles and Cell Sorting Cell sorter operator serves as PI/Lab Director Must conduct risk assessment Most knowledgeable of the work in their labs Each “operator” knows “their” instrument Teach Biosafety and work with operators Learn “Cell Sorting” and work with operators See procedure from start to finish Transport to/from and all steps in between Key Messages in ISAC 2014 Biosafety Have SOPs in place that provide a foundation for selection of controls at each BSL (BSL1, BSL2, BSL2-enhanced, BSL3) Evaluate sorters selected for biohazard use Not Principles and Cell Sorting all sorters created equal Minimize # of operators sorting biohazards (where applicable) Hands-on training and proficiency documentation Key Messages in ISAC 2014 Emergency procedures Know what a spill is for cell sorters (stream deviation) Use biosafety “common” sense Evacuate, allow aerosols to settle, be removed Know contamination zone of the sorter before sorting biohazards Develop decontamination SOPs Relationship / Partnership Cell Sorting Operators & Biosafety / EHS Professionals Biosafety/EHS Share: Risk Assessment and Risk Management Principles of Biosafety Cell Sorting Professionals Share: Knowledge of equipment (function, operation) Process flow (and more…) Yale Cell Sorting Biosafety Program Identification on campus of all high speed cell sorters SciQuest (past, new and future purchases) Core labs Department specific sorters Equipment questions on biohazard registration forms Training of EHS professionals (equipment recognition on inspections) Yale Cell Sorting Biosafety Program Campus user group meetings Lab inspections Core Facility registration form (where applicable) Testing & certification of HEPA filtered control devices (AMS’, Class I and II BSCs) Equipment validation testing Negative pressure verification Minimum PPE requirements for biohazards Yale Cell Sorting Biosafety Program Added Core Facility Manager to Yale BSL3 Subcommittee Share best practices Approved SOPs used as templates for new locations (starting point) Demo particle challenge testing and assessment Assist with authorization for biohazard use with new sorters Yale Cell Sorting Biosafety Program Clear “bands” established (CT biohazard regulations influence work location) Low Risk (BSL1) Moderate Risk (BSL2) Primary human materials, other human cells, defective pathogen vectors, non-human primate cells High Risk (BSL2-enhanced and BSL3) Risk Group 2 and 3 human pathogens Samples known to harbor human pathogens if used for research (CT State DPH registration required) Yale Cell Sorting Biosafety Program Negative pressure rooms for BSL2 (and higher) AMS at BSL2 (and higher) Containment aerosol challenge verification Trained, experienced operators (all levels) PPE (lab coat, gloves and full face protection) at BSL2 Gowns, 2 pair gloves, face shield, sleeves at BSL3 with respirator consideration based on risk Primary containment enclosure and AMS (BSL2-enhanced and BSL3) Power of Professional and Regional Sharing Journal articles Online posts (extra pulmonary TB) Rockefeller University Cell Sorting Biosafety Summit (Part 1 and Part 2) 2 Full Days on cell sorting biosafety hazards Best practices shared Many different approaches Q&A Forum Yale Flow Cytometry Core Facility: Services: Cell Sorting and Cell Analysis to 220+ Currently: PIs and 1000+ users 6 – High Speed Cell Sorters In the Anlyan Center, George St. And Amistad Building 14 – Analysis Machines In the Anlyan Center, Amistad, and 300 George St. Buildings How much has flow cytometry grown? PubMed Articles Citing Flow Cytometry: • • • • • 1974 – 1 1980 – 119 1990 – 2,288 2003 – 5,890 2013 – 10, 306 How many of you have a flow cytometer or cell sorter? What is a safety officer likely to encounter: “We have a FACS machine”, “It’s a cytometer” or “That’s just a FACS machine” What do you actually have on your hands? An Analyzer Or a Cell Sorter How does Flow Cytometry Work? + = A problem for EHS and everyone else is that we use the terms FACS and Flow Cytometry Interchangeably: BD FACSVantage - Sorter BD FACSCalibur - Analyzer* BD FACSVerse - Analyzer BD FACSJazz - Sorter BD FACSAria - Sorter BD FACSCanto - Analyzer BD LSRII - Analyzer -Definitely not sorter by Today’s standards Cell Analyzers: Cell Sorters: Pressures: 3-6 psi 20-70+ psi Aerosol Containment: Usually none Frequently AMS/Hoods Samples (at Yale): Always fixed Usually non-fixed Levels of Safety at Yale for analyzing samples: 1) Fixation – all samples run on analyzers* 2) On a sorter with an AMS – samples that cannot be fixed 3) On a sorter in a hood – samples that are potentially hazardous 4) On a sorter in a hood with respirators – samples that are infected/ hazardous What are the potential risks and hazards associated with flow cytometers and cell sorters ? Flow Cytometers/Analyzers: Greatest potential hazard or risk associated in running a cytometer: The users 1) Train every user 2) Establish clearly stated rules “But, I’ve been doing flow for years at XXXXX.” Why are you here? Can anything really go wrong with a sorter? The Good News: There are currently no laboratory acquired infections directly attributed to the process of cell sorting. (Holmes, Perfetto; Cyto 2010) The Bad News: Cell sorting is a procedure that intentionally creates droplets and aerosols. 80% of laboratory acquired infections are from an unknown route of exposure, but the majority are likely transmitted via airborne exposure. (Sulkin & Pike 1951, Pike 1979) The Other Bad News: Manufacturer trainings place little to no emphasis on bio-safety and the potential risks associated with cell sorting and cell analyzers. So where do you start? Framework for RA/RM Risk Assessment Risk Management Pathogen Practices (good work practices) Procedures Protective equipment (clothing and equipment) Personnel Place (facility design) Pathogen – Initial Risk Assessment Principal Investigator- Risk Group Classification• BMBL Biosafety in Microbiological and Biomedical Laboratories (BMBL), Current Edition (http://www.cdc.gov/biosafety/publications/bmbl5/) • Public Health Agency of Canada – Pathogen Safety Data Sheets and Risk Assessment (http://www.phac-aspc.gc.ca/lab-bio/res/psds-ftss/index-eng.php#l) • NIH Guidelines – Classification of Bio-hazardous Agents by Risk Groups (http://oba.od.nih.gov/oba/rac/Guidelines/APPENDIXB.htm) • ABSA Risk Group Tables for Infectious Agents (http://www.absa.org/riskgroups/index.html) Pathogen – Initial Risk Assessment Principal InvestigatorRisk Group Classification• Risk Groups (Gwladys Caspar, former Harvard University BSO) – RG1 “don’t drink it” – Analyzer or Sorter – RG2 “don’t touch it” – Sorter with AMS – RG3 “don’t breathe it” – BSL-3 Sorter – RG4 “don’t do it in MA/CT/Yale” • BARE – “Block all routes of exposure” (Ben Fontes, Yale EHS) Personnel• Training and extensive knowledge of the cell sorter and hood • Must have experience operating sorter outside of a BSL-3 setting prior • Health Screens and Blood storage by Employee Health • Bio-safety, Blood-Borne Pathogen, and BSL-3 Trainings and refresher courses must be completed regularly • EHS ensures personnel have a good track record in regard to Safety to be considered for BSL-2 or BSL-3 sorting What do you think this is? The preferred transportation vessel for analysis users. Proper sealable secondary containers Proper collection tubes that are properly sealed Clean Starting Area Organize all required items before starting experiments Cell Sorting Biosafety – 1) Provide sort operators with the appropriate tools to evaluate their ability to conduct sorts • Pre-sort discussion with the sort operator and pre-sort experiment questionnaires BSL-2 and BSL-3 sorts • • • • • • Identify the health risk BMBL Biosafety in Microbiological and Biomedical Laboratories (BMBL), Current Edition (http://www.cdc.gov/biosafety/publications/bmbl5/) Public Health Agency of Canada – Pathogen Safety Data Sheets and Risk Assessment (http://www.phac-aspc.gc.ca/lab-bio/res/psds-ftss/index-eng.php#l) NIH Guidelines – Classification of Bio-hazardous Agents by Risk Groups (http://oba.od.nih.gov/oba/rac/Guidelines/APPENDIXB.htm) ABSA Risk Group Tables for Infectious Agents (http://www.absa.org/riskgroups/index.html) Check Principal Investigator’s CT State Bio-hazard Registration Form for work with a particular agent • Add Sorting Facility to protocol as a location for research • Ensure the researchers conducting the research are on the protocol • Pre-sort discussion with the sort operator and pre-sort experiment questionnaires BSL-2 and BSL-3 sorts • First questions for us, • “Is your material fixed or non-fixed?” • “Is your material mouse, human, or other?” • “Is your material infectious?” • “Has your material been altered/treated in anyway?” • Based on the above answers we have the research complete a BSL-2 or BSL-3 questionnaire that we will keep on record • The questionnaires are reviewed in conjunction with the Environmental Health and Safety Office • We perform a risk assessment of the proposed sort • General Risk Assessment Guidelines Used I. Determine the agent, volume, and concentration II. Proposed practices/procedures (sorting in this instance) III. Proposed location and PPE IV. Training, experience, and health status of the workers Lo pressure sort (12 psi, 130-micron nozzle) Hi pressure sort (70 psi, 70-micron nozzle) Stream Askew Centered Stream Glo-Germ Bead Modified Testing• Glo-Germ particles are not ideal (tough to keep in suspension, clump, irregular shape) • Hank Pletcher (Penn.) and Yale Sorting Facility modified Glo-Germ protocol using Polysciences Yellow-Green (YG) Microspheres Testing Aerosol Containment Position No AMS/No BSC/No Tube Holder No AMS/No BSC/Tube Holder In AMS/BSC/No Tube Holder A >150 9 0 B 16 0 0 C 0 0 0 D 0 0 0 Any guesses on how many particles can be detected on the sash during this? ~ 4300 YG Beads in 8-minutes 273 YG Beads in one 10-minute test So what is the likely route of potential exposure for the sort operator? 80% of known infections in another study were associated with a “break down” in work practices, or adherence to good microbiological practices and safe technique may have prevented these events. (Phillips 1965) Can we perform BSL-3 sorting in your current Flow Cytometry dungeons?