Sustainable Practices for Improved Environmental Compliance

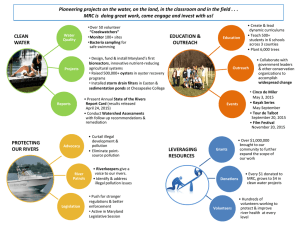

advertisement

Sustainable Practices for Improved Environmental Compliance by the Foundry Sector Prof. G. L. Datta Formerly: Professor in Mech Engg at IIT Kharagpur Presently: Chancellor, K L University, AP gldatta_05@yahoo.co.in The Talk Foundry Sector Sustainable Practices Environmental Compliance FOUNDRY INDUSTRY 8 to 10 thousand years old Presently there are 40 to 50 thousand foundries in the world World annual production is about 90 million tonnes of castings worth about 250 billion US$ About 2 million people are working in the foundries globally. FOUNDRY INDUSTRY First foundry was set up in China during the Shang dynasty about 3500 years ago. First cast iron foundry was established in England by Abraham Darby in 1709 AD. John Wilkinson of England obtained a Patent on cupola furnace in the year 1794 AD. FOUNDRY INDUSTRY IN INDIA Castings were made in the Indus Valley Civilization in the middle ages. Presently there are about 4500 foundries in India. India’s annual production exceeds about 7 million tons of castings. India ranks fourth in the world in terms of annual production. India’s annual production is about 15 billion US$. FOUNDRY INDUSTRY Global average casting productivity: 34 tons/man.year. Casting productivity in Japan: 97 tons/man.year. Casting productivity in India: 16 tons/man.year FOUNDRY INDUSTRY IN HOWRAH Once Howrah used to take pride in being called the ‘Manchester of India’ with a strong industrial base in Howrah. It possessed once about 500 foundry units. There are now about 300 left. Traditionally the foundries were run as family business enterprises. Some units had the privilege of having professional expertise while others did not. FOUNDRY INDUSTRY IN HOWRAH Total employment is about 50,000 including about 40,000 contract laborers Some of the common practices: Green sand manual molding Cast iron castings Divided blast cupola Why Sustainable Practices? Activities in a Foundry are prone to creating various kinds of pollutants – the degree of pollution depends on the practice The Foundry Sector in Howrah has a big stake in terms of generation of employment and wealth Thus the question of sustainable practices. Before we talk about the sustainable practices, let us have a look at the profile of the Howrah Foundry Industry. SWOT ANALYSIS ON HOWRAH FOUNDRIES Strengths Weaknesses Opportunities Threats STRENGTHS OF HOWRAH FOUNDRIES It has a good legacy, which needs to be sustained. Given proper coordination and cooperation, 300 odd foundries employing about 50,000 workers directly and an equal number indirectly – providing livelihood to a few lakhs of people. There is abundant cheap labor, thanks to the large migrant population in this area. There exist good quality technical institutions in and around this region, which can supply trained human resources needed at different levels. STRENGTHS OF HOWRAH FOUNDRIES Contd… The foundries have capability to take up both ferrous and nonferrous castings practically of any size and complexity. There are many experienced and capable foundrymen in this region capable of taking any challenge. Availability of quality pig iron in this region is an added advantage to the ferrous foundries. STRENGTHS OF HOWRAH FOUNDRIES Contd… Good quality support industries needed for running the foundry industry (e.g., foundry equipment and consumable manufacturers) exist in this region. With the ‘Foundry Park’ in sight the Howrah Foundries will soon find it easier to derive benefits of working together and produce castings. There exists a strong, motivated and committed ‘Foundry Association’ working for the welfare of the Howrah Foundries. WEAKNESSES OF HOWRAH FOUNDRIES Most of the foundries in this region still practice old and obsolete technology and hence are not capable of fulfilling the quality, supply deadline and competitive price requirements. There is a concept of “gala mal” in some of these foundries. Foundry rejections are rather high ranging from 12 to 20% or more making productivity low and price noncompetitive. WEAKNESSES OF HOWRAH FOUNDRIES ‘Brand Name’ situation is mostly nonexistence. The physical environment and pay packages are not sufficiently attractive to ‘lure’ young talent to work in the foundries. Some of the foundry units operating in this region are too small (tiny), which may not be economically viable. WEAKNESSES OF HOWRAH FOUNDRIES Contd.. No foundry has any R & D section worth its name. Automation, and use of IT and CAD/CAM softwares can be found only to a limited extent while foundries elsewhere have been able to improve their productivity by adopting some of these technologies. WEAKNESSES OF HOWRAH FOUNDRIES Contd.. Many foundries are working under the threat of closure due to noncompliance with pollution control norms. In many foundries again, the need for HRD finds low priority. In-house testing and inspection facilities are mostly nonexistent. Opportunity for outsourcing these facilities is also considered inadequate. WEAKNESSES OF HOWRAH FOUNDRIES Contd.. The environment inside and outside the foundries is polluted: Air pollution from fumes, gases, and dust, Water pollution from use of chemical binders, Sound pollution. WEAKNESSES OF HOWRAH FOUNDRIES Contd.. Till the Howrah Foundries move to the Foundry Park, they would be working in isolation and would not be able to derive the benefits of services like ‘sand reclamation’, ‘sand testing’, ‘non-destructive evaluation of castings’, ‘heat treatment’, ‘CNC machining’, and so on. Labor productivity and installed capacity utilization are rather low as compared to some of the Southern States of our country not to speak of countries like China, Japan and Germany. OPPORTUNITIES FOR HOWRAH FOUNDRIES The Indian Foundry Sector is presently experiencing a boom, which is being aided by a thriving economy and an exponential growth in the Automobile and Engineering sector. With the boom in the automotive sector in the country, in general, and in Bengal, in particular, demand for automotive castings made of aluminium alloys, grey iron and ductile iron is predicted to double in the next five to ten years. OPPORTUNITIES FOR HOWRAH FOUNDRIES Contd.. The economic growth of the country coupled with the favorable industrial policy of our Government, has given a fillip to the demand for castings to meet various industrial needs. Our foundries in this region have to gear up to meet the present and the future demand. With financial banks adopting more ‘loanfriendly’ attitudes, fund raising for expansion and modernization of foundries has become easier than ever before. THREATS TO HOWRAH FOUNDRIES Availability of castings from elsewhere at a price lower than that Howrah Foundries can afford has to be overcome by improving overall productivity. Incapability to produce quality castings would shy away even the existing customers. THREATS TO HOWRAH FOUNDRIES Contd… Non-adherence to pollution control norms would invite demand for closure from appropriate authorities. Types of Pollutants Created by Foundries Gaseous – CO, CO2, SO2, Nox Suspended Particulate Matter Water Pollution Pollution due to solid waste Standard Norm Cupola Capacity (Melting rate) Less than 3 tonne per hour 3 tonne per huor or more Particulate Concentration (mg / m3) 450 150 Why Environmental Compliance? Compliance is a must to improve and to sustain quality of life of all living beings. Pollution Prevention Reducing Pollution – Sustainable Practices By use of energy efficient practices Check efficiencies of all machines – blowers, pumps, compressors, air conditioners, lighting systems, molding machines, sand conditioning plant, mold drying ovens, heat treatment furnaces, Reduce wastages – air and oil leakages, running machines when not required, spillage of liquid metal. Reducing Pollution – Sustainable Practices ------contd By improving productivity: Reduce casting rejection Reduce wastage of liquid metal – increase metal temperature by exothermic reaction Improve liquid metal casting yield – better methoding practice, improved mold design. Reducing Pollution – Sustainable Practices ---- contd Operating cupola in the most efficient way by ensuring: Correct blast rate and blast pressure Correct distribution of air between the top and lower tuyeres Non-turbulent entry of air into the cupola Correct sizing of the cupola parameters such as tuyere area, well depth, stack height Good operating and maintenance practices Feed material control – shape, size, weight, sequence. Reducing Pollution – Sustainable Practices---- contd By using improved design of furnaces and equipment – cupola height, divided blast, furnace lining, use of recuperators, exhaust system, dust catcher, Employing induction furnace for melting Employing efficient heat treatment and mold drying ovens. Good Practices Practice “Green Foundry” – energy efficient practices and use of renewable sources of energy Practice ‘lean casting manufacturing techniques’ Reduce waste and recycle waste Protect workers, the public and the environment Reduce risk of spills, accidents and emergencies Good Practices Pursue quality of life through human resource development, Have faith in science, technology and human resources, Promote a work culture symbioting world of knowledge and work through reengineering, participation and motivation, Build a partnership between industry, govt agencies, funding agencies and academia. CONCLUSION To understand sustainable practices needed for environment compliance, SWOT analysis of Howrah Foundry industry has been presented, Possible common measures have been identified and discussed. THANK YOU VERY MUCH FOR YOUR KIND ATTENTION