投影片 1

advertisement

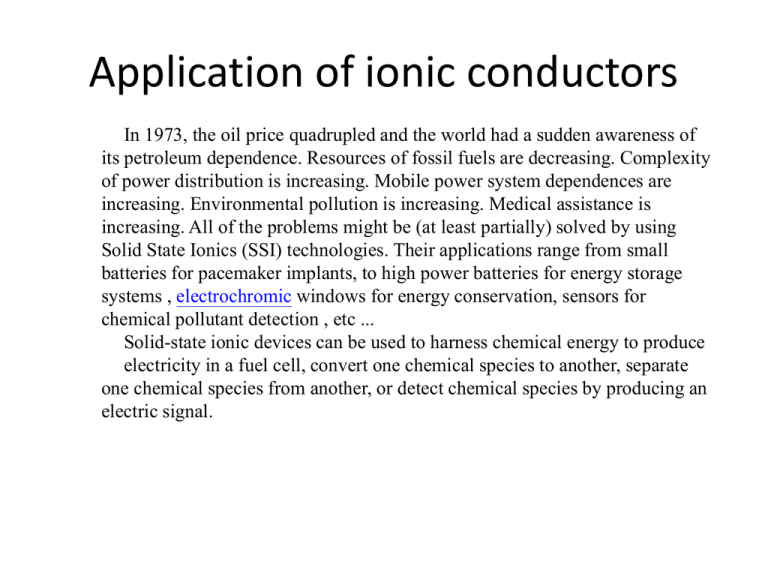

Application of ionic conductors In 1973, the oil price quadrupled and the world had a sudden awareness of its petroleum dependence. Resources of fossil fuels are decreasing. Complexity of power distribution is increasing. Mobile power system dependences are increasing. Environmental pollution is increasing. Medical assistance is increasing. All of the problems might be (at least partially) solved by using Solid State Ionics (SSI) technologies. Their applications range from small batteries for pacemaker implants, to high power batteries for energy storage systems , electrochromic windows for energy conservation, sensors for chemical pollutant detection , etc ... Solid-state ionic devices can be used to harness chemical energy to produce electricity in a fuel cell, convert one chemical species to another, separate one chemical species from another, or detect chemical species by producing an electric signal. Gas sensors Two potentiometric designs have evolved: surface-modified solid electrolyte gas sensors and mixed potential gas sensors. In the former, the surface of a solid electrolyte is coated with an auxiliary phase which will react electrochemically and reversibly with the analyte and generate an interfacial potential. Sensitivity and selectivity to the analyte are provided by the auxiliary phase, e.g., the Na2CO3 /NASICON system can be used for CO2 sensing This approach allows the use of several conventional ceramic solid electrolytes, including YSZ, β-alumina, or NASICON to construct sensors for many gases especially the environmental gaseous pollutants such as CO2, CO, NOx , SOx , H2, Cl2, and NH3, etc. An important advantage of this approach is the development of detection methods that survive harsh conditions where typical liquid electrochemical sensors would be inappropriate. In a mixed potential sensor design more than one electrochemical reaction takes place at the electrodes so that a mixed potential is established by competing reactions. The catalytic activity of the electrode material is particularly important, e.g., the Pt/YSZ/Au sensor can measure CO and hydrocarbons due to the difference in catalytic activities between the Pt and Au electrodes. Oxygen Sensor PO' 2 emf = " RT PO 2 ln ' 4F PO 2 PO" 2 yttria stabilized zirconia (YSZ) The cell operates at temperatures 500~1000 ℃, can be used to measure oxygen partial pressure as low as 10-16 atm Typical response of a commercial ZrO2oxygen sensor to change on Air/Fuel of an engine The main application of oxygen sensors in the gasoline run automobiles is to control the air-to-fuel ratio (λ). The oxygen partial pressure changes abruptly in the vicinity of the stoichiometric mixture of the air and the fuel (λ = 1: air = 14.5 kg; fuel = 1 kg). The figure shows the characteristic sensor output, the λ-curve, for a range of air-fuel mixture in the combustion engine. The emissions of toxic gases such as CO, NOx , and hydrocarbons (HC) depend on the λ point at which the engine functions. In the fuel rich region, the emission of CO and HC dominates and in the lean region, NOx emission is larger. These exhaust gases are converted to non-toxic gases CO2, N2, and H2O by a three way catalytic converter located in the exhaust system. The O2 sensor output is fed back to the engine control so that the engine operates between the rich and lean fuel conditions centered around the stoichiometric ratio. HCs Sensor Pt/YSZ/Nb2O5 sensor, using Nb2O5 and Pt electrodes on tape-cast YSZ. The EMF response of this sensor to different concentrations of propylene (HCs)in air, in the temperature range 500-700°C. Sensor SO2 Pt mesh T=790oC Ag V1 emf (mV) V1 Pt catalyst air+SO2 Ag V2 Pt 3.63%Y2(SO4)3 in pure Ag2SO4 Ag Al2O3 K2SO4 K2SO4+1%Ag2SO4 PSO2=1000ppm Graphite embedding Ag+Ag2SO4 reference electrode V2 PSO2=100ppm V1 V1 PSO2=10ppm days Schematic diagram of a K2SO4-electrolyte sensor and its observed emf variation in time Variation of emf with time for swapping of SO2 concentration from 20to 1000pp oxygen generators Ceramic oxygen generators (COG) are receiving the greatest attention for medical and aerospace applications because they can readily produce a pure oxygen gas stream from ambient air. Compact COGs are being developed to provide a continuous supply of oxygen-enriched air for people with breathing disorders. Similarly, these devices can enrich the breathing oxygen concentration for high altitude aircrafts. More recently this technology has sparked the interest of NASA for space exploration. Because of the distance involved, if we are to travel to other planets in the future, we need to utilize available planetary resources. The technology envisioned to make this possible is based on a COG converting CO2 to O2 and CO. Experimental results demonstrating the efficacy of this technology are shown by the Faradaic oxygen production from CO2/CO gas mixtures . Faradaic production of O2 from CO/CO2 gas mixture in a ceramic oxygen generator. Catalyst Fuel cell- proton conductor Proton exchange membrane (PEM) fuel cell The proton exchange membrane is one of the most advanced fuel cell designs. Hydrogen gas under pressure is forced through a catalyst, typically made of platinum, on the anode (negative) side of the fuel cell. At this catalyst, electrons are stripped from the hydrogen atoms and carried by an external electric circuit to the cathode (positive) side. The positively charged hydrogen ions (protons) then pass through the proton exchange membrane to the catalyst on the cathode side, where they react with oxygen and the electrons from the electric circuit to form water vapour (H2O) and heat. The electric circuit is used to do work, such as power a motor. Fuel cell- oxygen conductor A solid oxide fuel cell is made up of four layers, three of which are ceramics (hence the name). A single cell consisting of these four layers stacked together is typically only a few millimeters thick. Hundreds of these cells are then connected in series to form what most people refer to as an "SOFC stack". The ceramics used in SOFCs do not become electrically and ionically active until they reach very high temperature and as a consequence the stacks have to run at temperatures ranging from 500 to 1,000 °C. Reduction of oxygen into oxygen ions occurs at the cathode. These ions can then diffuse through the solid oxide electrolyte to the anode where they can electrochemically oxidize the fuel. In this reaction, a water byproduct is given off as well as two electrons. These electrons then flow through an external circuit where they can do work. The cycle then repeats as those electrons enter the cathode material again. Electrochromic smart car window Electrochromic Properties of Sol-gel Coating of Nb2O5 and Nb2O5:Li+ It can be observed that, close to -1.0 V, there is an increase in the cathodic current associated with Nb2O5 reduction with simultaneous Li+ cation insertions. During this process it is observed a change in the optical properties of the films, from transparent to gray color. Variable resistor devices As an active material, inserted tungsten trioxide, MxWO3, is often used in switching applications between very high and very low resistance: low inserted tungsten trioxide is a dielectric while high inserted is a metallic conductor . A more linear dependence between resistivity and insertion was observed in mixed conductors based on some silver salts. They have been used in the design of controllable resistors. Figure shown above gives an example of such an electrochemical device. Medical Applications of Solid State Ionics Biomedical applications of solid state power sources; biofuel cells; and iontophoretic* and related devices used for controlled transdermal** drug delivery and monitoring of physiological parameters. •Iontophoresis is a technique using a small electric charge to deliver a medicine or other chemical through the skin. **Transdermal is a route of administration wherein active ingredients are delivered across the skin for systemic distribution. Examples include Transdermal patches used for medicine delivery, and Transdermal implants used for medical or aesthetic purposes. Biofuel cell Penny Sized Biofuel Cell